If you’re looking to elevate your shop’s plasma cutting capabilities and achieve the precision and excellence your projects demand, You’ve Come to the right place

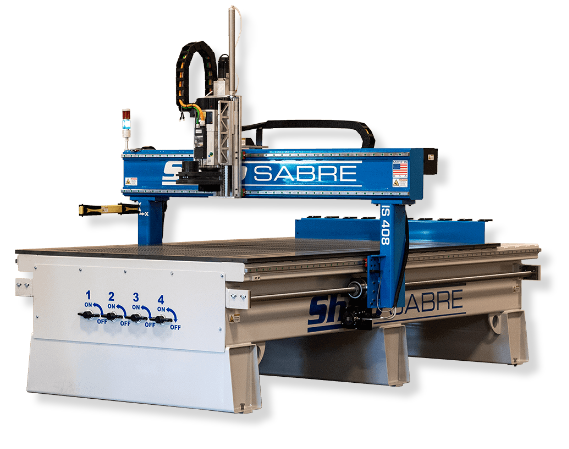

ShopMaster CNC Plasma

Sidekick CNC Plasma

Crossfire XR

ShopSabre TC Series

Questions?

Not sure which machine is right for you and your production? Schedule a free consultation with one of our in-house experts for personalized, one-on-one guidance.

When it Comes to Your Plasma System, Don’t Settle For Mediocrity

The ShopSabre Plasma Table – Often imitated but never duplicated, ShopSabre’s American-made CNC Routers feature cutting-edge technology and premium components, the kind typically only seen on much higher-priced machines.

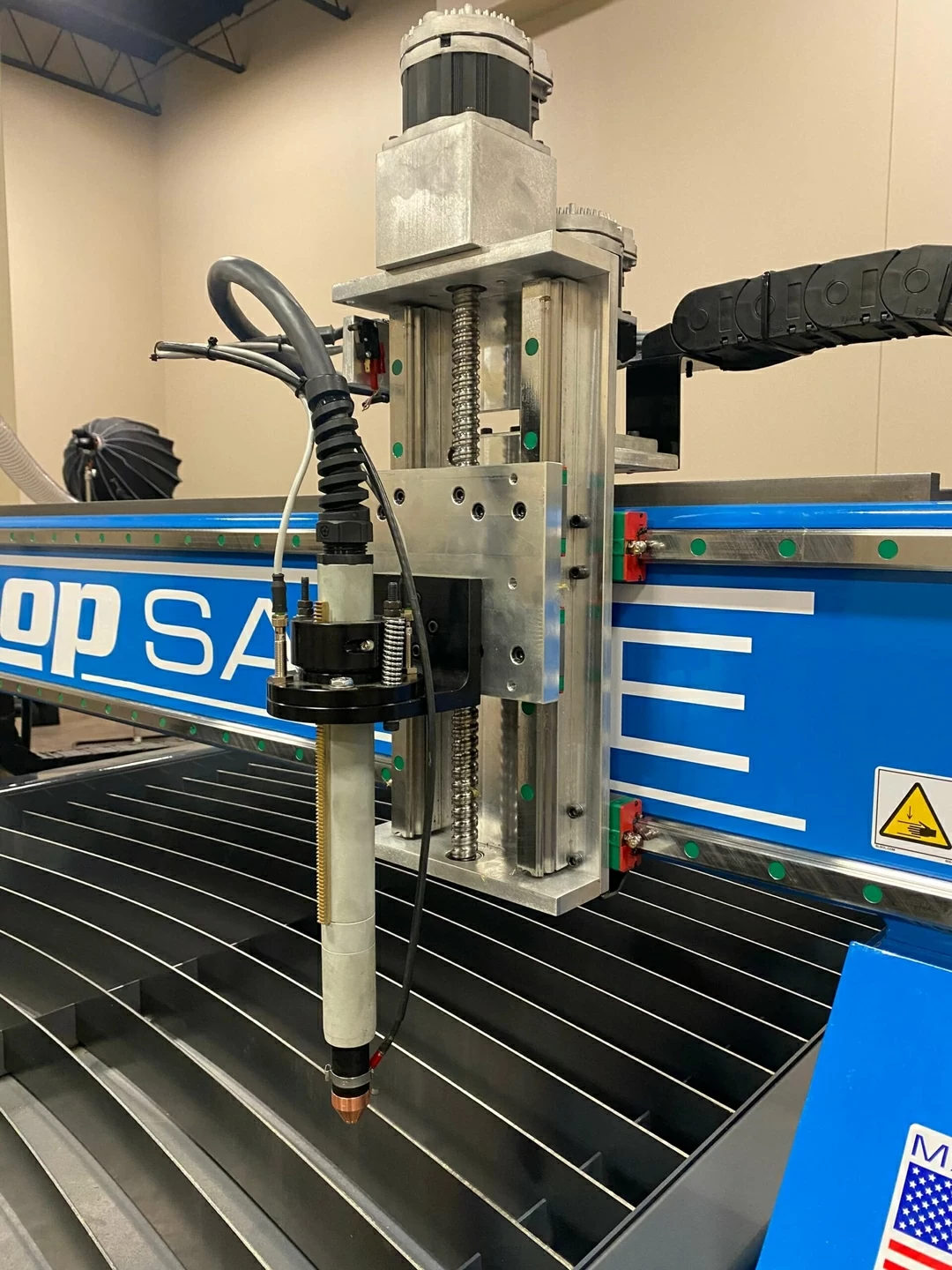

Each plasma table we manufacture can be configured in a wide array that suits your exact business needs. From advanced dust control features to impressive drill heads and state-of-the-art tool changers, you’ll be empowered to take your plasma table to the next level.

Embrace ShopSabre CNC Plasma Tables and seize the ultimate control over your machining.

Parts to Keep You Running

In house inventory & same-day shipping keeps your business on track with less downtime.

CNC Training For Life

We offer a variety of free training tools to help you make the most of your CNC machine. From CNC Plasma Tables to CNC Routers, ShopSabre offers training to help you succeed in your business or hobby, with unmatched customer service in the industry.

Financing Available

Receive better rates and better terms with our versatile financing and leasing options.

A Plasma Cutter Should Work The Way You Do

ShopSabre is proud to bring you True American-made CNC plasma cutting tables at a price that can’t be challenged by anything in a similar price range. Each CNC plasma table made by ShopSabre, features state-of-the-art manufacturing technology and high-quality components.

Every CNC Plasma table is loaded with capabilities not optionally offered by the competition. Our range of custom CNC plasma table options allows you to unleash the possibilities and versatility of your CNC plasma table. Not all plasma cutters are the same!

From 4th-axis pipe cutting options to advanced cutting solutions of High Definition, our various CNC machines can be configured to deliver in any industry and tailored to handle a wide range of applications, weights, speeds, and quality cuts.

Don’t be limited by the out-of-the-box capabilities of cheap or imported cutting products. Make your next CNC Plasma Table, A ShopSabre CNC Machine.

Why ShopSabre For Your CNC Plasma Table?

Our commitment to industrial strength and unbeatable customer service ensures your CNC plasma table or cutter will deliver the perfect results.

Every ShopSabre CNC table or plasma system is carefully built to perform from the moment you get it.

At ShopSabre, our CNC plasma tables have many advantages over the competition, including:

-

Top-rated material, Technology, and construction are often found only in capable machines retailing for $100,000 or more, saving you on cost

-

Industrial-strength gantry upright construction for the highest level of precision and speed for any industry

-

High-precision motion components including state-of-the-art drive technology ensure the highest accuracy, cutting forces, and operation performance possible, including heavy usage

-

Advanced and name-brand electronics to give you the most torque and precision in any CNC plasma table system competitively priced

-

CNC grade motion controller with PC OS compatibility gives you the ease of a computer with the same capabilities you’d find in a standalone control tower

-

Fully Welded Metal Frames – No Bolts or Kit Systems

-

Industry Engineered and Tested – Not Piece together Kits, allowing for greater versatility

-

No assembly or Installation is required – drop it in place, connect it to power, and go to work

-

Each CNC Plasma Table is custom-built for your specific needs and budget with many available options already included when compared to manufacturers

-

Complete warranty and FREE lifetime tech support to give you peace of mind

-

Truly USA-engineered, developed, fabricated, assembled, and supported

CNC Plasma Table Uses & Applications

CNC plasmas have a wide range of applications and can handle virtually any metal. Our plasma tables are commonly used for:

- Construction and carpentry

- Custom Fabrication Shops

- Prototyping & R&D

- Plate Processing – Nested Work

- Hot Rod & Race Shops

- Farming Industry

- Signs and Decor