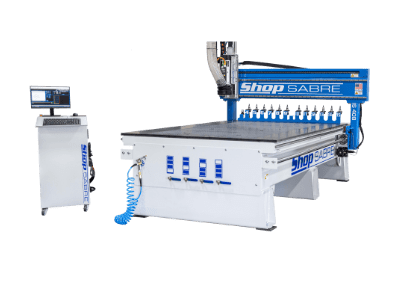

Everything You Need in a CNC Router

When buying a CNC router, the service and quality are the two most critical items. You need a machine that works when you need it, and that machine needs to deliver excellent performance every time you put it to work. At ShopSabre CNC, we’re committed to building CNC routers of unmatched quality and value combined with unbeatable customer service. Ultimately the build quality and technology will determine your machine’s life expectancy and performance capabilities.

CNC machines are a big investment and with that many people are tempted by Low prices claiming to be the same but many of these companies are simply Chinese imports, suppliers of lower quality technology, or even kit machines all showing lower price tags due to their inferior build quality and technology. If you buy one of those machines, you’ll soon find yourself in need of a new one. That’s why we tell you to “buy your second machine the first time” and save yourself the hassle, headache, and hidden costs found with lower build quality or non-American made equipment.

Don’t be fooled by other machines who claim to be fastest growing or more industrial, Facts remain more people trust the ShopSabre CNC brand than any other manufacturer due to our quality and competitive pricing. This makes us a true industry leader in the CNC router market. With more machines replacing our competition every month, it goes to show the advantages to buying your second machine your first time, and our customer retention proves this.

Below we have outlined the key elements of a CNC router. We hope this will help you understand why we are the top CNC Router manufacturer for your money and why you will truly outperform the competition with our equipment! We also recommend checking out the higher priced CNC router machines and then looking at our systems. With similar materials, components, and overall design, you’ll quickly see why our machines offer the best performance at the best value.

Framework

Framework

Structural

ShopSabre CNC routers are constructed of the top-rated North American structural steel tubes and heavy wall steel plate. We don’t use fabricated tubes (Bent Steel), extruded aluminum, or angle iron in our machine frames. Our systems are constructed of structural tube steel welded with no assembly required, giving you the same quality you’d find in machines retailing for $100,000 or even more.

Unbeatable Precision and Accuracy

We build our frame to withstand all the projects you need to tackle. Not only is the base of our machine stress relieved for tension reduction but we also aerospace mill the PRO, IS, and IS-M Frames for added tolerances & precision and then run them through a number of quality tests including a Faro Measurement to assure each frame meets our expectations and your demand. We don’t stop there though, We also take it one step further than the competitors and stress relieve & mill the gantry as well to ensure both the frame and the gantry are square. These factors give you the most rigid and accurate assembly in the machine class.

In the PRO, IS, and IS-M Series tables the utilization of the Aerospace milling center gives you an edge over the competition. Precision milling the frame, gantry, and related components to ensure there are no tolerance issues or accuracy problems comes standard on our Machine Tool Grade solutions! Ultimately the machine is only as good as it’s foundation so don’t settle for a CNC router machine that is simply bolted together, picked off a shelf and pieced together, or worse purchased in foreign countries and imported to be resold to you. Our frames are a work of art on their own – truly engineered with the use of high end FEA software to properly load test the systems because they are built to be second to no other design, and with over 20 years of experience, we have proven they can withstand the growth and changes in your everyday business operations.

Gantry Construction

Gantry Construction

Industrial Quality

Regardless of what level ShopSabre CNC router you purchase we don’t put a lightweight gantry on an industrial frame and call it complete. All ShopSabre CNC Routers come standard with a Structural Tube Steel Gantry that has been performance milled and stress relieved. All ShopSabre CNC Router gantries are designed with the same FEA Software used on the frame to assure the bearing spacing, tube size, and wall thickness is properly fitted for the machine capacity. In fact, the ShopSabre CNC Pro, IS, and IS-M Series Routers all come with the same gantry construction that is found on the high production $100,000+ series tables. If you look at our most economical machine the ShopSabre 23, this model still uses a Steel Gantry Spanning Bridge for added rigidity. ShopSabre CNC routers continuously go above and beyond by pairing the industrial framework with industrial structural steel tube gantry bridges. The details matter and our attention to them ensure you get the highest level of precision from your ShopSabre CNC Router.

Industrial Performance

ShopSabre CNC also uses a paired set of over-sized structural steel tubes for the gantry uprights (structural tube steel uprights on the IS-M, IS, PRO, and RC Series), allowing you to push the machines harder and faster under load with less deflection, harmonics, and cutting issues. This upgraded design also allows us to provide you with higher clearances than our competition standard which gives you a true edge over your competition. Many machines claim to be industrial, but when you look at the gantries you will find there are few that can truly stack up against a ShopSabre CNC Router machine technology.

Aluminum CNC machines are a thing of the past and only benefit the company selling you them as it allows them to purchase cheaper electronics and increase their margins. There is an engineering reason you don’t find much Aluminum in high end routers or milling centers. Proper Engineering is why we too choose to use a higher strength design to increase your cutting performance, machine rigidity, and overall cutting speeds. Don’t be fooled into purchasing something that is uncommon to Industrial CNC Router manufacturing.

Motion Components (Drives, Guides, and Motors)

Motion Components (Drives, Guides, and Motors)

High-Precision Components

(Shown Above) ALL ShopSabre CNC Routers are all built with same high-precision components. We use top rated 25MM linear guide rails with matching 25MM Linear Guide Bearing Blocks utilizing internal quad roller sets and triple wipers on EVERY axis of EVERY machine. We use two bearing blocks on each rail with two rails per axis to ensure cut forces are equally distributed over the rail to reduce the amount of wear and noise. Many competitors use inferior components that include non-name brand bearings, older precision roller & V-Guide roller technology, precision slides, or undersized lighter weight 15-20MM linear guide ways.

Another key part of this is the bearing spacing themselves, very few machines offer the FEA engineering like we do therefore ShopSabre’s bearing spacing is wider to provide you a higher cutting force and more stability under load.

Just like a football player who widens their stance to get a competitive advantage over their opponent, the Bearing spacing on a ShopSabre gives you an advantage over your opponents!

Self-Cleaning Systems, Low Failure Rates

The triple-sealed technology of the bearing blocks used on our CNC router systems ensures that regardless of how much debris and dust you create from your routing, you will not get failure to the bearings when properly maintained. This design also makes the CNC router machine a self-cleaning system, this ensures while running you do not need to worry about wiping down the rails or watching for build up. Simply put it to work and come back when the job is complete.

On the PRO, IS, and IS-M Series we even protect the Y Axis Rails by reducing their exposure to the debris and dust to further improve performance, reliability, and reduce maintenance costs/time.

Best-in-Class Ball Screws

On our Machine Tool Grade Industrial CNC routers (ShopSabre PRO, IS, and IS-M Series), the motion on all three of the axes (X, Y, and Z ) are driven by high precision ball screws which incorporate our “Whip Free” design with matched ball nuts which also happen to be the largest diameters in our class. In fact, in many cases our ball screws will rival the diameter of machines that retail well into $100,000.00 price point. We don’t believe in using smaller flimsy ball screws or cheaper lead screw technology to save cost. These are truly industrial grade ball screws similar to what you find on higher priced and higher caliber machines retailing for double the price. Unlike the designs of our price competitors, our ball screw design is dual Y axis driven on the PRO, IS, and IS-M Series, giving you an even cut force no matter where you are cutting on the machine. This also significantly improves cutting tolerances and performance while maximizing the cutting speeds of your machine.

A few of our competitors run a cheap lead screw design or, even worse, many of them utilize a less accurate technology in the form of a rack and pinion drive system which will cause unnecessary wear for the X & Y Axis bearings and motors while reducing cut forces and machine precision. The ShopSabre ball screws also have anti-backlash ball nuts mounted in angular contact bearing blocks to ensure the highest accuracy possible. You will also find that on our PRO, IS, and IS-M we are using the latest ball screw technology in rotational ball nuts means NO Whip exists in these machines – that outdated technology is a thing of the past, on a ShopSabre you get the latest in technology and this results in high performance!

Also standard on the RC, PRO, IS, and IS-M Series is our Servo Control System. In fact, our PRO, IS, and IS-M use the most Advanced Mitsubishi A/C digital super servo drive in the class with matching amplifiers and glass encoders.

These motors are simply the highest accuracy, highest torque, and most dependable technology in the machine class.

The IS & IS-M Series uniquely comes with the only dual Y axis ball screw drive system paired with 2 kilowatts of Y axis power for UNDER $70,000 made in the U.S.A.

Our machines give you the quality of much more expensive machines at the price of cheaper import products. A higher price tag doesn’t always mean better technology, let the facts speak for themselves – nobody offers more technology in the class than ShopSabre CNC!

At ShopSabre, you always get the best technology for the lowest investment.

Ask our sales for more details about the drive system technology on our CNC routers. We promise you won’t be disappointed.

ShopSabre CNC Controller

ShopSabre CNC Controller

Power of Industrial, Convenience of PC

ShopSabre CNC uses the best of both worlds when it comes to our CNC controller. Unlike many competitors, we DO NOT use cheap hobby controllers such as Mach 3, and we most definitely do not stick our clients with something proprietary built. Many cheaper controls cause programming issues and compatibility problems long term because they don’t have the technology to stay up to date. We use an industrial PCI driven controller that has been conveniently integrated to operate with a P.C. environment to give you maximum control over your CNC system.

From the outside our control functionality looks like a normal PC, but behind the scenes there is an industrial CNC grade dedicated PCI controller with integrated Micro Processor and all the same hardware you’d find in a standalone control tower for thousands more. Just like our machines, the controller is also Made in the U.S.A. to assure the best support and continued service. Our CNC routers are built to be the best on the market and provide you the motion control technology you expect from a quality machine without the intimidating appearance of a CNC control tower.

CNC Controllers have never been so easy to operate – Many of our customers without any CNC experience are operating their machine in as little as 2 hours from receiving it!

Don’t settle for complicated controllers which require days of training, our controller will blow you away!

Top-Quality Connection

Our system does not connect to the machine with a cheap serial port, printer port or USB cable. We use a true CNC grade industrial connection via a high definition 37-pin connection. Unlike many other systems, ours lets you alter drawings at your CNC system and store files at your CNC with a massive 250GB Solid State hard drive. You can also Network your machine, perform at machine on-board diagnosis, and even operate various Windows Compatible programs without compromising your machine control capabilities. Simply load your CAD software on the machine computer so you do not need to walk away to make changes to a file. These machines are truly built for today’s users and tomorrow’s technology.

No Special Training and Maximum Capabilities

The ShopSabre CNC also requires NO special training because it is designed to be as easy as the cheaper quality controller systems with point and click technology but with all the capabilities found in the $100,000+ machines. The ShopSabre controller has a built-in microprocessor that ONLY drives your CNC machine while the PC processor runs the PC and any programs you might have running. This means Windows DOES NOT operate your ShopSabre CNC system but is present for those programs that require it. The ShopSabre CNC controller also has available USB drives to ensure you can plug in your flash drives and external hard drives. The ShopSabre CNC system also comes with Ethernet capabilities as well as network capabilities and an optional USB wireless connection available.

Not Your Average PC Style Controller

Many people are given false information from competitors who are intimidated by our controller that all PC style controllers are hobby or lower quality, but this is simply not true. As CNC technology advances, so do computers. With 20+ years of ingenuity, our machine computers and CNC router machines are VERY compatible and provide some of the best CNC routing capabilities. After all, you can control your garage door, lights, and sprinkler systems with a cell phone, so offering industrial control with Windows compatibility is a breeze!

The ShopSabre CNC system has EVERY capability of a machine with standalone controllers, including many capabilities that the competitors cannot offer (even machines costing $100,000.00) such as part/job preview, at machine CAD, on-board diagnosis, bit offsets/compensations, tracing, direct import, jig setups and remembrance, job restarts, re-runs, speeds/feed over-ride, and mid file tooling changes along with other various ShopSabre CNC features. The ShopSabre CNC Controller is designed to function in an industrial environment, so you can be assured the dust and dirt won’t cause an issue for these controls.

Also, don’t worry about Windows updates that the competitors try to play off as the end of your machine. Windows updates won’t affect your ShopSabre CNC router, in fact we have designed our machines to be able to stay current so unlike dedicated controls your machine can continuously advance with technology. Our engineers make everything work together in harmony. The controller can easily be updated with Windows so you will never run into a compatibility problem with our FREE lifetime support!

Now if you simply MUST have a standalone style control ShopSabre is the first CNC Router manufacturer in the word to pair CNC Routing with the Mitsubishi M8 Series Controller on our IS-M Model. The M8 Series by Mitsubishi is the world’s fastest CNC Control and brings a dedicated control with the ease of ShopSabre interface. The M8 Series by ShopSabre is the world’s quickest and most accurate controller available in industry and comes standard on our IS-M Models.

Hold Down (Vacuum & Clamping)

Hold Down (Vacuum & Clamping)

Built for Your Needs and Your Budget

ShopSabre CNC Routers have an answer for any budget and power demand whether you are a full production shop working with cabinets or a one-off shop building custom designed signs or maybe a prototyping shop working on the next big thing. We can include a vacuum hold down system to fit your need and budgets. We offer the industry’s most powerful Single-Phase System as well as many High Performance Three Phase solutions. Don’t worry though, if vacuum is not in the budget right away or you simply need/prefer your clamps, we also offer T-Slot tables and if you want the best of both worlds the ShopSabre combo hybrid Vacuum/T-Slot tables to give you limitless material hold down abilities.

A League of Our Own

Why the ShopSabre vacuum systems are in a league of their own is simple: the ShopSabre CNC Router tables with our HiFlow vacuum option is specifically paired to each size of table giving you more CFM for hold down with better results. Many companies try to sell you “Universal” vacuum tables, low power pumps, or cheaper flexible tube connections. If you look at the facts many manufacturers truly do not know the science behind vacuum hold down and with factually not enough CFM for a 4 x 8, 5 x 10, or even bigger system you are the one that has to deal with the headache. If you look at machines retailing for $100,000 or more, those tables often include twin pumps or a single larger pump to ensure you are not watching your money move around the table. ShopSabre pairs industrial high suction pumps on all tables that typically provide suction levels almost twice of what comparable CNC Router machines will quote you for similar costs. The ShopSabre vacuum systems also come with independent vacuum zones allowing you to turn the air on and off to various areas as necessary so you do not waste suction on areas that you are not cutting on.

ShopSabre’s HiFlow Vacuum technology is the best in the industry giving you 50% more flow than competing machines, we have found you cannot cut what you cannot hold down!

We also are one of the few companies that truly took the time to engineer the vacuum table top and make sure the flow is as even as possible while allowing the capabilities of gasketing if you prefer (not required on most of our vacuum tables).

More Versatile Machines

The Hybrid T-Slot clamping tables are an option we introduced to the market several years ago that recess aluminum T-tracks into the table top and bolts those tracks to the steel frame below to allow you to add T-slots without the cost of a normal expensive full aluminum table top. We understand the need to remain versatile without spending unnecessary amounts of money.

Also included in all T-slot applications are the set of industrial clamps providing you the necessary components to get started. Don’t settle for a system that is going to cause you to slow the cuts down or force you to secure your materials down with tape, glue, or screws when a ShopSabre CNC Vacuum or T-Slot hold down system can make your job easier!

The Birth of ShopSabre CNC

The Birth of ShopSabre CNC

While constructing his next CNC router, Jim performed more market research and was amazed that no one offered an industrial quality machine under $60,000. Jim decided to take his design to the Woodworkers show in Atlanta, GA, where he received a lot of attention, accolades, and over a dozen requests for orders. Potential customers were willing to wait for their new machines as they understood the quality and components put into the design.

After returning home, Jim constructed a facility for the manufacturing of CNC machines in the U.S.A. With the help of his two brothers, four sons, two cousins, and his wife, Jim opened ShopSabre CNC and began changing the way the CNC industry works.

A few years after opening, Jim developed the first ShopSabre CNC plasma machine along with the technology that would make ShopSabre a leader in its class.

Spindles/Cutter Heads

Spindles/Cutter Heads

The Right Options for Your Needs

ShopSabre CNC router systems once again have an answer for any budget or need. Our ShopSabre 23 and RC Models come standard with a 3.25HP Porter Cable Variable Speed Router with industrial power cord and machine mounting bracket. Our more industrial models the PRO, IS, and IS-M come standard with Electric Fan cooled HSD Italian Spindles available in Manual, Quick, or Auto Tool Changing! Popular Spindle options include the 4HP HSD electric fan cooled spindles with ER25 collets, 9.3HP HSD electric fan cooled spindles with the ER32 Collet system, 5HP & 10HP HSD auto tool changer spindles with ISO30 and ER32 compatibility (Also available in HSK capabilities), and of course we also offer the larger 13HP HSD HSK System for our IS-M Series machines.

We also have special order spindle options for applications with other needs.

Everything You Need

All of our spindles come standard with a high quality Variable Frequency Drive (VFD) to control spindle RPM ranging from 1,000-24,000 depending on the model. The VFDs we offer also run on single or three phase at no additional cost to you allowing you to install your new ShopSabre in your home garage or industrial setting without the loss of performance or cutting abilities. Due to the higher quality VFD we use standard you can also run all your spindles on a S1 (100% Duty) Rating giving you higher performance, better load capacity, longer life, and no loss in power on Single Phase. ShopSabre CNC Routers also have the option to install a 5 position or 10 position tool rack or on the IS-M we offer a 10 Position Rotary Direct Drive Carousel tool changer with bi-directional change. Don’t be fooled by competitor’s quotes, Many only provide you with the tool changer head and 1 tool position and then force you to buy the additional features. We believe in providing the entire package so you go to work quicker without headache.

ShopSabre does not cut corners or hide anything. If you purchase a 5 position tool changer you get 5 complete positions which include the collets, cones, tool forks, and wrenches with vice. Yes, you read that correctly, even the wrenches & vice are included. This goes for any number of positions. ShopSabre CNC routers also come standard with an attached tool measure switch with ANY number of tool positions so you are not limited in the number of tools you can have because the tool measure switch is using a position in your tool changer.

Top-Rated Spindles

To prove we don’t cut corners, we encourage you to research HSD spindles and compare them to their industry. You will find that all our HSD spindles are rated the best on the market. We expect you to be able to get many years of use out of your spindle with little to know maintenance required. Our HSD spindles are Italian made (Italians make the best spindles) and U.S.A. supported and easy to maintain.

Don’t be fooled by lower priced machines which many times use off-brand spindles, water cooled technology, or air cooled solutions – Many times these solutions come from China at a lower price but are sold to you for comparable costs to a quality spindle. Many water cooled spindles are an inferior technology that requires additional equipment and maintenance. If the spindle is not an HSD, then it’s not the best. If its water cooled it will require more maintenance than electric fan cooled because of the water pumps and other various maintenance items, and they cool only when running whereas electric fans run anytime they are hot and reduce the amount of power loss seen by shaft driven fans. Don’t purchase a system that will leave you looking for more power or better quality.

Our Spindles are also Electric Fan cooled which increases the duty cycles, torque curves, and cutting performance all while reducing power consumption and maintenance costs. With an electric fan cooled you don’t have a bucket of water sitting next to your machine like the cheap water-cooled solutions.

Be sure to contact our sales team for more information on how a ShopSabre can make a difference in your shop!

RELATED MACHINES

IS-M Series

Industrial Series (IS)

IS EVA Series

PRO Series

RC Series