Boge Rotary Screw Air Compressors

Description

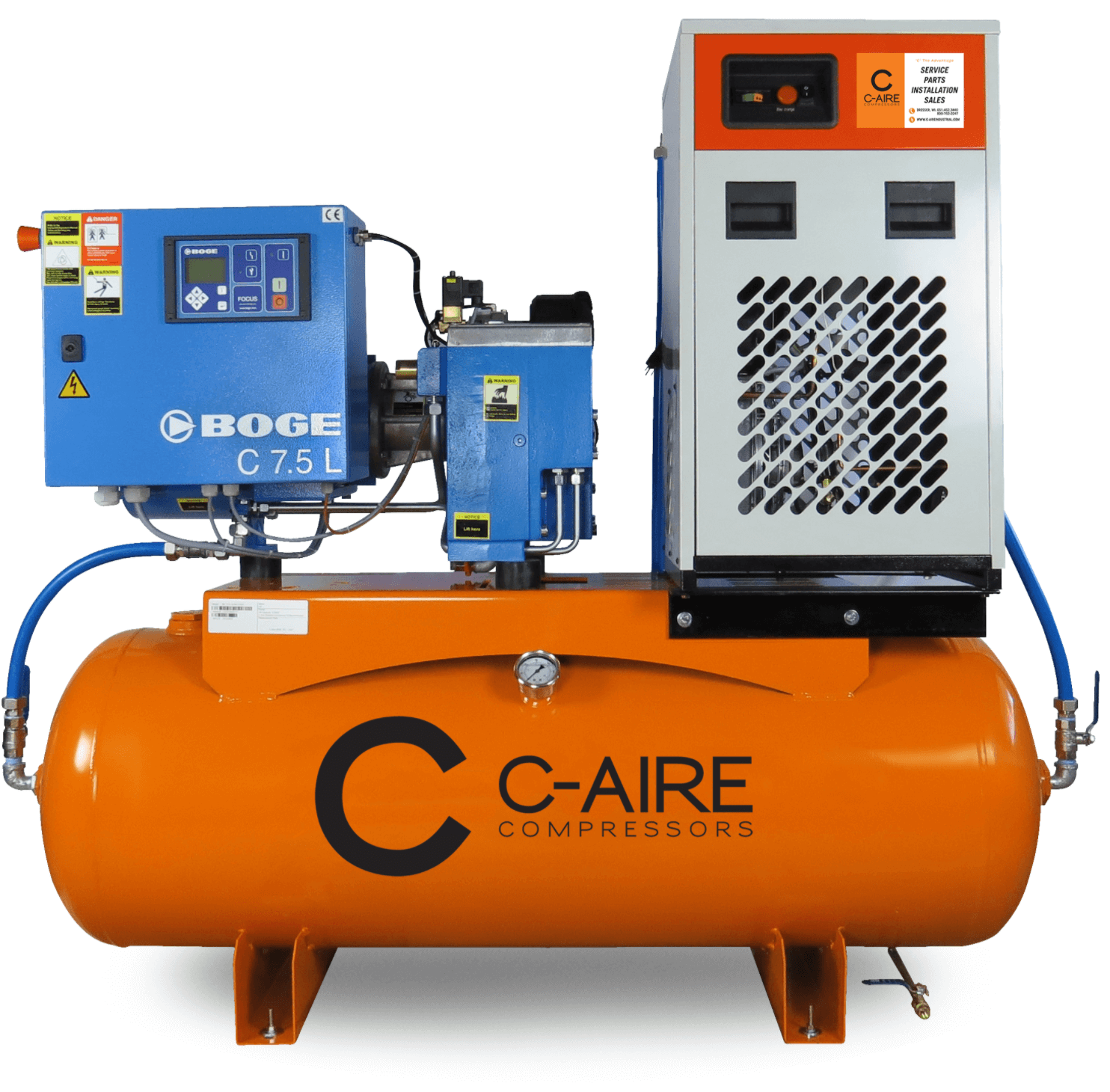

C SERIES 7.5HP 125P Boge Rotary Screw: System mounted on 80 Gal. Horizontal Receiver Refrigerated dryer.

Read MoreRead Less

How Rotary Screw Air Compressors Work

- Two intermeshing rotors in a housing having an inlet port at one end and a discharge port at the other end

- Most Rotary Screw units are single stage

- Motors run continuously. The inlet port is closed when the desired PSI is achieved and opens again as needed

- Lubricant injected into the compression chamber serves three functions

- Lubricant injected into the compression chamber serves three functions

- Air exiting the rotors passes through a sump/separator. Directional and velocity changes are used to separate most of the liquid.

- The remaining aerosols in the air are separated by a Coalescing Filter, resulting in generally 2-5 parts per million of lubricant carryovers

- Lubricant (carrying much of the heat from air compressing) passes through the cooler before returning to the rotators

Additional Notes

Downloads

Specifications

| Phase | 3 |

|---|---|

| CFM | 30 |

| PSIG | 125 |

| Hz | 60 |

| Voltage | 208 |