The Best CNC Routers & Plasma Machines for Metal Work

Precision matters when it comes to metal fabrication, and so does power. Whether you’re cutting non-ferrous metals, engraving brass, dealing with steel, or machining aluminum parts for production, your CNC machine needs to deliver repeatable accuracy under serious stress.

But with so many machines on the market, how do you know which is the best CNC machine for metal work?

In this guide, we’ll break down what makes a CNC machine great for metal, who it’s built for, and how to choose the right fit based on your workload, materials, and goals.

What Makes a CNC Machine Good for Metal?

Not all CNC machines are built to handle metal. Some are better suited to wood, plastics, or foam, and pushing those machines into metal can leave you with broken tools, botched jobs, and wasted material.

If you’re serious about working with metal, you need a machine designed for it from the frame up.

Here’s what to look for:

- Rigidity: Cutting metal generates serious force. A metal CNC machine needs a rigid frame and gantry system to hold position under load and reduce vibration.

- High-torque spindle: You’ll want a spindle with enough torque to power through dense materials without bogging down or overheating.

- Precision motion control: Ball screw drives and servo motors provide the accuracy and repeatability needed for intricate metal work.

- Proper tooling and chip management: Metal cutting produces heat and debris. To maintain performance and protect your machine, you need the right tooling, feeds/speeds, and chip evacuation system.

The Best CNC Routers for Metal Work

If you’re running full-time production, whether for fabrication, aerospace, or industrial prototyping, you’ll want a heavy-duty CNC router or plasma system built for 8+ hours of daily metal cutting. Look for fully welded frames, tool changers, and precision drive systems.

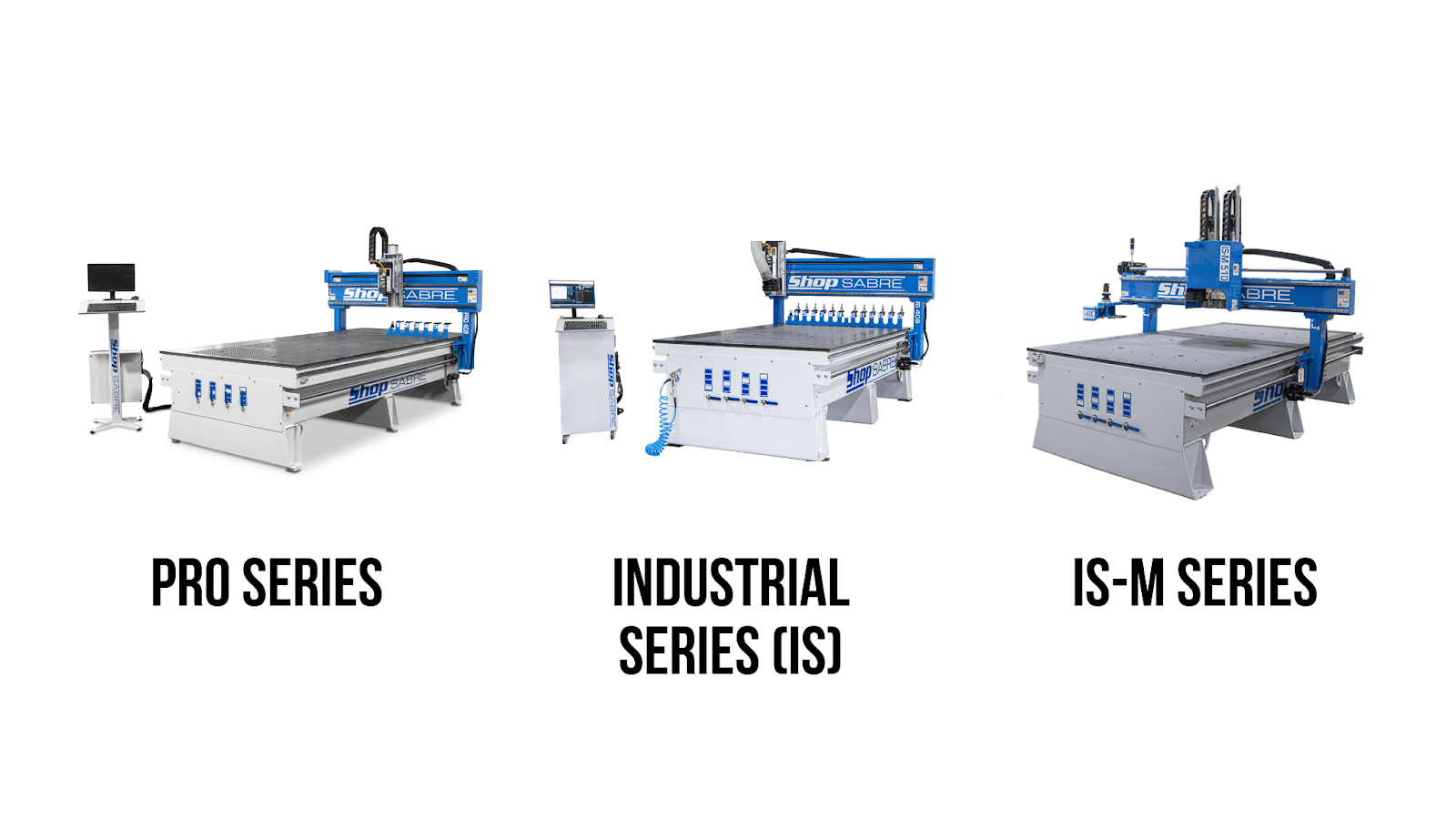

IS-M Series

If you’re serious about precision and tired of wasting time and material, the IS-M Series is where to start. These routers are designed for shops that need speed, accuracy, and the kind of reliability you only get from bed-milled frames and rigid gantry assemblies.

The IS-M is also the world’s first CNC router to feature the Mitsubishi M8 series control, an industry-leading interface that gives you serious control over your cuts.

Industrial Series CNC Router

Don’t let the word “industrial” scare you off. This series is built for shops with serious goals, but not $100,000 budgets. These metal CNC machines are engineered to compete with top-tier production routers while keeping affordability and reliability at the forefront.

Thanks to anti-backlash ball screws on all axes and our proprietary “Whip Free” Technology, you’ll get repeatable precision even on tight-tolerance metal projects.

Check out our complete list of the best metal CNC machines for small businesses.

The Pro Series CNC Router

The Pro Series CNC routers are the Swiss Army knife of the lineup for businesses that tackle everything from cabinets to signage to non-ferrous metal parts like aluminum, brass, and copper. These machines feature oversized work areas, intuitive point-and-click software, and true plug-and-play performance.

Perfect for shops juggling high-mix, custom work, especially if your workload includes materials beyond just metal.

Our complete lineup of aluminum and brass machining systems is built for serious shops that can’t afford downtime.

What About Steel and Ferrous Metals?

If your shop needs to cut steel, stainless, or other ferrous metals, a CNC router isn’t the right tool for the job. These materials are too dense and will quickly wear down or damage a router system.

For ferrous metals, you need a CNC plasma machine or a fiber laser.

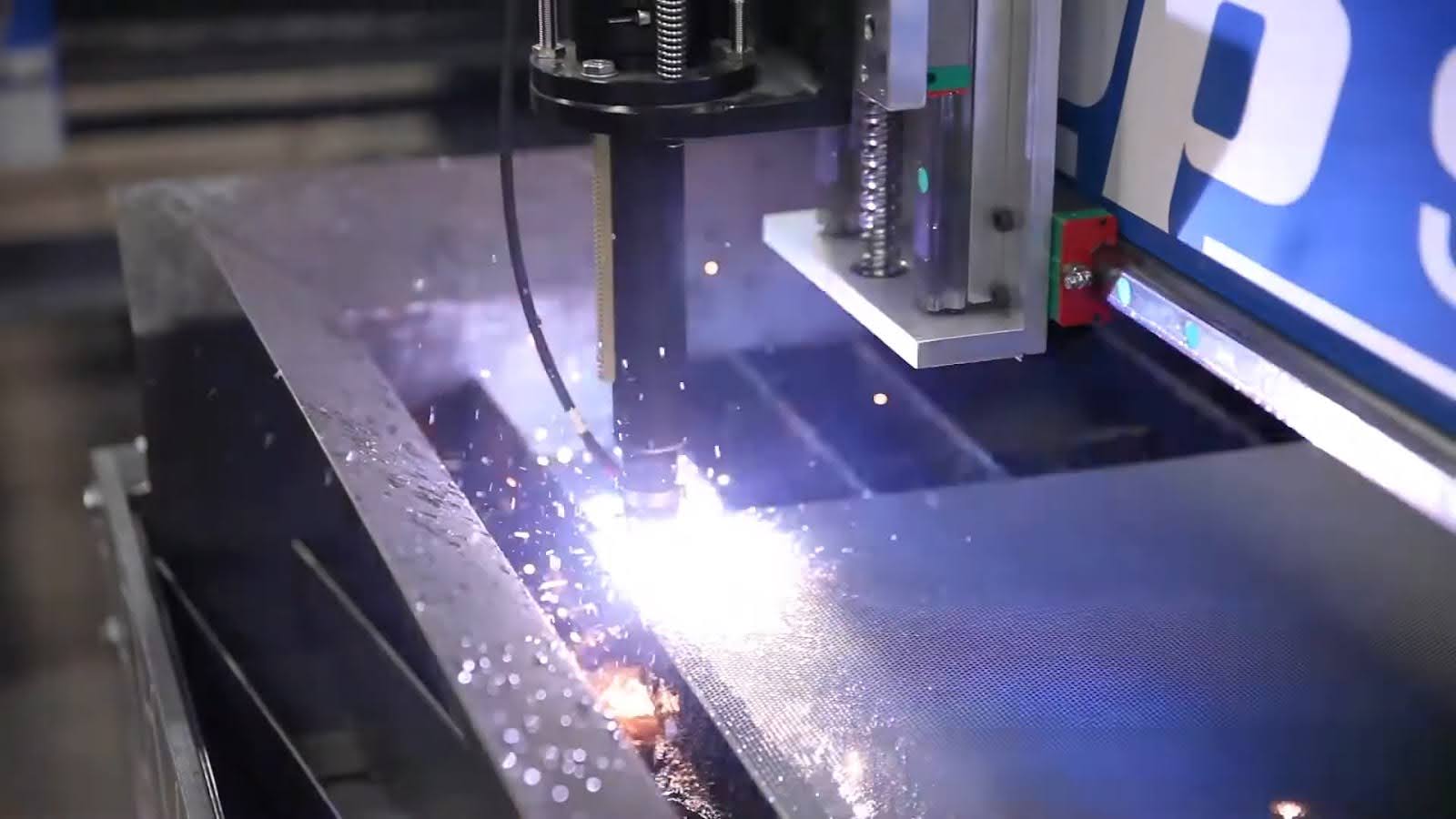

Best CNC Plasma Machines for Steel & Ferrous Metals

SideKick CNC Plasma

Designed with a fully welded structural steel frame and a heavy-duty gantry, the SideKick CNC Plasma can handle the heat.

Every SideKick includes high-torque, high-accuracy motors with encoder feedback on the X, dual Y, and Z axes. Direct-drive planetary gears give it the power and precision to run 1-2 hours a week or 8+ hours a day, without wearing out or slowing down.

If you’re looking for a light industrial plasma with versatility to offer light-duty routing, the SideKick is the most advanced hybrid table in its class. Fully assembled and ready to go within minutes of delivery.

ShopMaster CNC Plasma

Need to cut steel all day, every day? The ShopMaster Series is built to thrive under production pressure. Designed for shops running two or three shifts a day, this machine brings elite performance without the six-figure price tag you’d expect.

The ShopMaster features a low-center welded steel frame for maximum weight transfer and rigidity. It’s equipped with Mitsubishi AC digital servo motors and glass encoder technology across all axes, paired with direct-drive planetary gears for elite speed, accuracy, and reliability.

This machine cuts at up to 2,500 IPM and includes a built-in 24″ water table with pneumatic bladder control for easy water level adjustment. A convenient part catch tray makes cleanup and part removal fast. Prefer a down-draft system? The ShopMaster offers an optional zone-controlled down-draft setup to match your workflow.

Compatible with Hypertherm XPR and Thermal Dynamics UltraCut systems, the ShopMaster is built for high-definition plasma cutting and serious throughput, ideal for fabrication shops, automotive manufacturers, and industrial operations that can’t afford downtime.

Go Beyond Plasma With the FiberSabre CNC Laser

If steel is your metal of choice, the FiberSabre is your next move. From stainless and carbon steel to aluminum, copper, and brass, the FiberSabre CNC Laser delivers flawless results where plasma starts to fall short.

Choose the 2kW FiberSabre for shops that want high-performance laser cutting on standard 220V single-phase power without the need for major electrical upgrades. Step up to the 6kW FiberSabre when you’re pushing thick material and high-volume production.

Every model is powered by Mitsubishi AC digital servo motors for exact motion control, with a powered Z-axis, advanced safety enclosures, and preloaded material libraries to get you cutting faster. Pull-out drawers and clean-out trays keep your workspace efficient and ready for the next job.

Whether you’re building parts, frames, or high-finish components, the FiberSabre gives you the control and consistency serious metalwork demands.

So, What is the Best CNC Machine For Metal Work?

Not every machine is right for every shop.

- Aluminum, brass, copper? → Choose a CNC router.

- Steel or stainless? → Go with a CNC plasma or Fiber Laser.

The good news? You don’t have to compromise. From entry-level models to industrial-grade workhorses, ShopSabre offers some of the best CNC machines for metal — machines that are tested, proven, and backed by real support teams right here in the U.S.