Description

PLASMA POWER. ROUTER PRECISION.

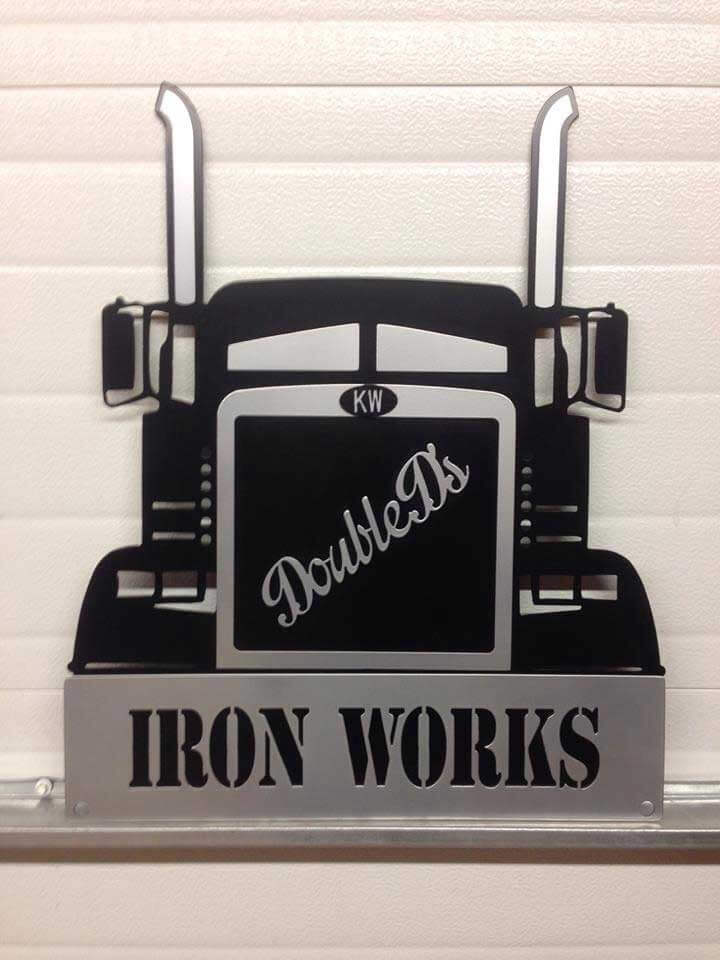

The ShopSabre SideKick CNC Plasma Series is built to give you an edge over the competition. Entry-level pricing meets industrial-grade design, delivering $60,000 worth of technology at a price you can afford! Whether you need a CNC plasma machine for occasional use or full-time production, the SideKick Series is engineered to perform—from 1-2 hours a week to 8+ hours every day.

The SideKick Series is FEA-engineered, designed, and manufactured in the U.S.A. It features the heaviest frame in its class, built from large structural steel tubes welded into a single-piece frame. Paired with our industry-renowned structural steel gantry, the SideKick is built to handle the cutting forces of routing and the heat tolerances of plasma—consistently outperforming the competition. Every SideKick comes standard with high-torque, high-accuracy motors with encoder technology on the X, dual Y, and Z axes, combined with direct-drive planetary gears for precision, reduced maintenance, and maximum power.

Loaded with the same high-end electronic components found on larger industrial machines, the SideKick delivers unmatched capabilities without breaking your budget. Perfect for manufacturing plants, automotive shops, fabricators, and schools, the SideKick arrives fully assembled and ready to work within minutes.

Need Plasma and Routing in One Machine?

The SideKick is the most advanced combination table on the market. Simply add one of our CNC router packages, and you’ll be able to plasma cut metal and route wood with ease—whether you’re a hobbyist or a full-production shop.

Contact us today to learn more about the ShopSabre SideKick Series CNC plasma.

Highlighted Features

- Dual-driven Y-axis (long axis) for enhanced stability and accuracy

- High-torque industrial closed-loop brushless motors with encoder technology for precise control

- Direct-drive planetary gear reduction on the XY-axis for smoother operation

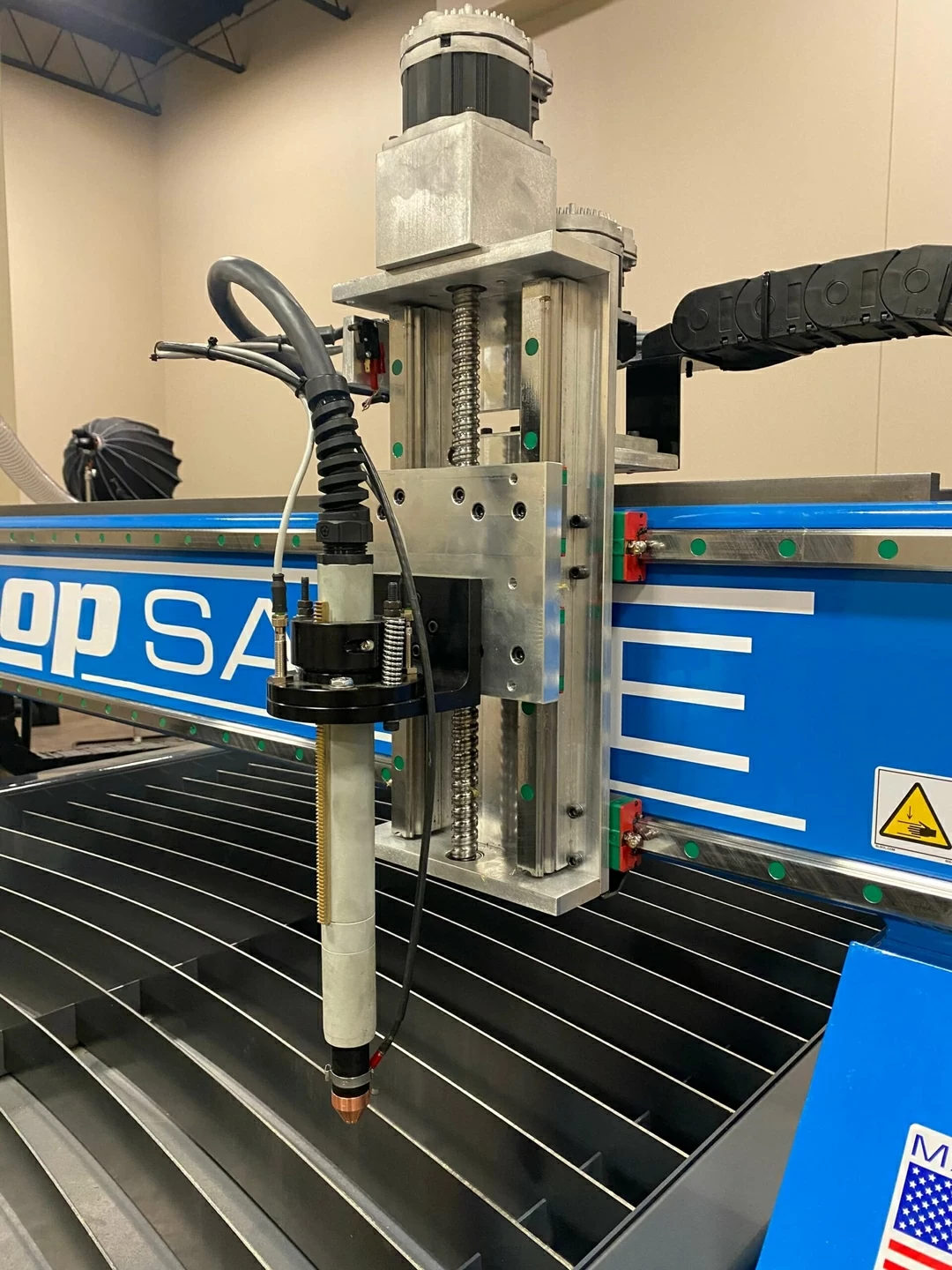

- Advanced direct-drive ball screw Z-axis for superior cutting precision

- Industrial welded, stress-relieved, and aerospace-milled structural steel tube gantry with 8″ clearance – Watch our steel vs aluminum video!

- 6-leg welded steel tube frame with cross-bracing for increased rigidity – no extruded aluminum or bolt-together designs, and no assembly required

- High-performance 25MM linear profile guide rails and bearings with quad rollers on all axes

- ShopSabre-exclusive Floating Drive Technology for improved XY motion, reduced maintenance, and increased torque

- Breakaway torch mount with a built-in level for easy alignment

- Advanced digital torch height control with Ohmic Touch System – Ask for Details

- Integrated Touch Distance Control for accurate material sensing

- Industrial continuous flex robotic wiring enclosed in wire carriers for protection and noise isolation

- Factory-installed table slats with steel brackets – standard water table or optional down-draft system available

- 12-month subscription to Hypertherm ProNest LT Unlimited & EnRoute Fabrication 7 for nesting, sign-making, and more

- Easy-to-learn software with point-and-click CAD/CAM abilities – (Watch our plasma control screen video)

- Pre-configured plasma cut chart and material library for optimal settings

- At-machine solid-state hard drive for easy job storage and high-speed multi-axis controller technology

- Tracing technology as seen on Powerblock TV – (Watch our search and restore video)

- Operator control system with monitor, keyboard, mouse, and Windows OS, fully network-capable via USB and internet

- Free lifetime SabreNation tech support via phone, email, and remote diagnostics – (Watch our support video)

- Lifetime access to SabreNation training and SabreNation University

- Comprehensive warranty included for peace of mind

- Quick and effortless installation – machine ships fully assembled, no setup required

- MADE IN THE U.S.A. – American-manufactured and engineered using FEA software – (Watch our engineering video)

- Optional router accessories available for expanded routing capabilities

- Expandable options to grow with your business – (Watch our expansion equipment video)

Well Equipped

Includes:

- Welded structural steel frame with a steel gantry bridge and reinforced uprights

- Ball screw drive technology on the Z-axis with planetary drives and ShopSabre Floating Drive Technology for rack-and-pinion XY-axis

- 25MM linear guide rails and bearings on all axes for smooth, precise motion

- Ethernet/network-ready controller with an at-machine PC running Windows OS

- 12-month software license for Hypertherm ProNest LT and EnRoute Fabrication

- Closed-loop hybrid digital motors with encoder technology and individual amplifiers featuring an alarm system

- Automated torch arc confirmation for improved cutting precision

- Digital torch height control with on-the-fly monitoring, one-button adjustment, and a pre-programmed material library for Hypertherm Cutter settings

- Enclosed wire management system for durability and organization

- Electronic torch collision detection with error monitoring, self-alignment, and impact protection

- Limit switches and boundary sensing for enhanced safety and precision

- Emergency stop button for immediate machine shutdown in critical situations

- Auto material touch (Ohmic Touch) with a fail indicator for reliable material sensing

- Steel table bed with reinforced steel slats and brackets

- Welded, leak-tested 3” water table with 5 gallons of ShopSabre Plasma Defense Water Treatment

- Hypertherm Powermax45 SYNC Plasma Cutter with machine torch connectivity and full system integration

- XY Zero laser sights for precise material alignment and quick zero referencing

- Machine maintenance kit for easy upkeep

- ShopSabre SabreNation support via phone, email, and remote connectivity for the life of the original owner

- Lifetime access to SabreNation training and university resources for continuous learning

Some items may be able to be removed or modified depending on needs

SideKick 4 |

SideKick 8 |

SideKick 10 |

SideKick 12 |

|

| Footprint | 81" x 70" x 67" | 81" x 118" x 67" | 93" x 145" x 67" | 105" x 166" x 67" |

| Cut Area | 52" x 49" | 52" x 98" | 65" x 122" | 78" x 146" |

| Z Clearance | 8" | 8" | 8" | 8" |

| Z Travel | 9" | 9" | 9" | 9" |

| Cutting Capacity | up to 2" (Oxy-Fuel Recommended for over 1") | up to 2" (Oxy-Fuel Recommended for over 1") | up to 2" (Oxy-Fuel Recommended for over 1") | up to 2" (Oxy-Fuel Recommended for over 1") |

| Positional Repeatability | +/-.002" | +/-.002" | +/-.002" | +/-.002" |

| Rapid Traverse | 1500IPM with Closed Loop Motors and Planetary Gear Drive | 1500IPM with Closed Loop Motors and Planetary Gear Drive | 1500IPM with Closed Loop Motors and Planetary Gear Drive | 1500IPM with Closed Loop Motors and Planetary Gear Drive |

| Well Equipped | $21,695.00 | $22,695.00 | $25,495.00 | $27,495.00 |

| Get a Quote | Get a Quote | Get a Quote | Get a Quote | |

Finance for as low as $375.00/month |

Finance for as low as $395.00/month |

Finance for as low as $440.00/month |

Finance for as low as $475.00/month |

Questions?

Are you not sure which CNC machine is right for you and your production? Schedule a free consultation with one of our in-house experts for personalized, one-on-one guidance.

SideKick CNC Plasma Features

Industrial Precision Frame

ShopSabre CNC frames are FEA-engineered and tested, constructed from massive 4x4 structural steel tubes that are welded for added rigidity. Each SideKick Series frame features six legs for increased floor contact and superior vibration control. Each leg is cross-braced and reinforced with steel tubes connecting at least three points, enhancing stiffness and load capacity.

SideKick CNC Plasma Features

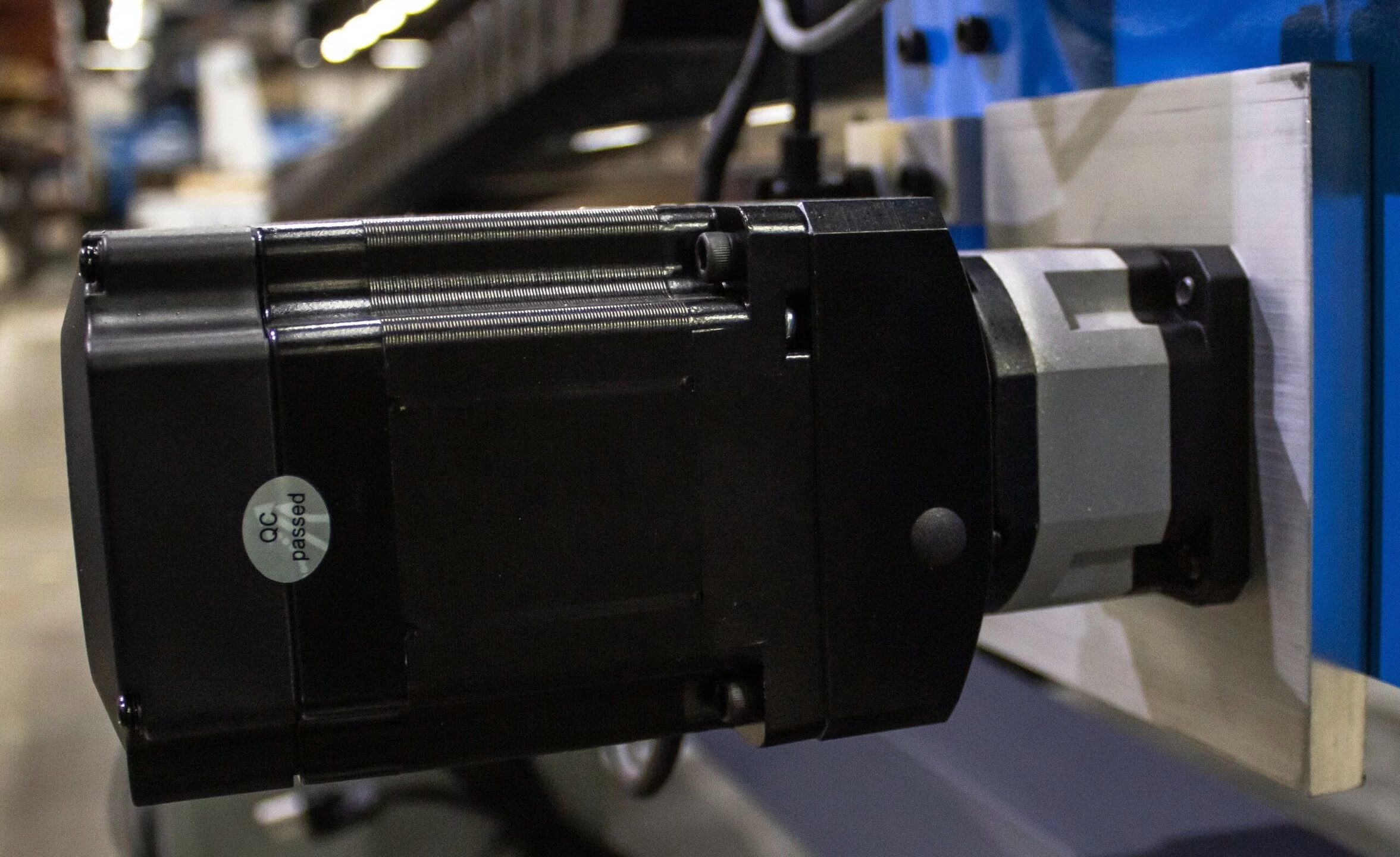

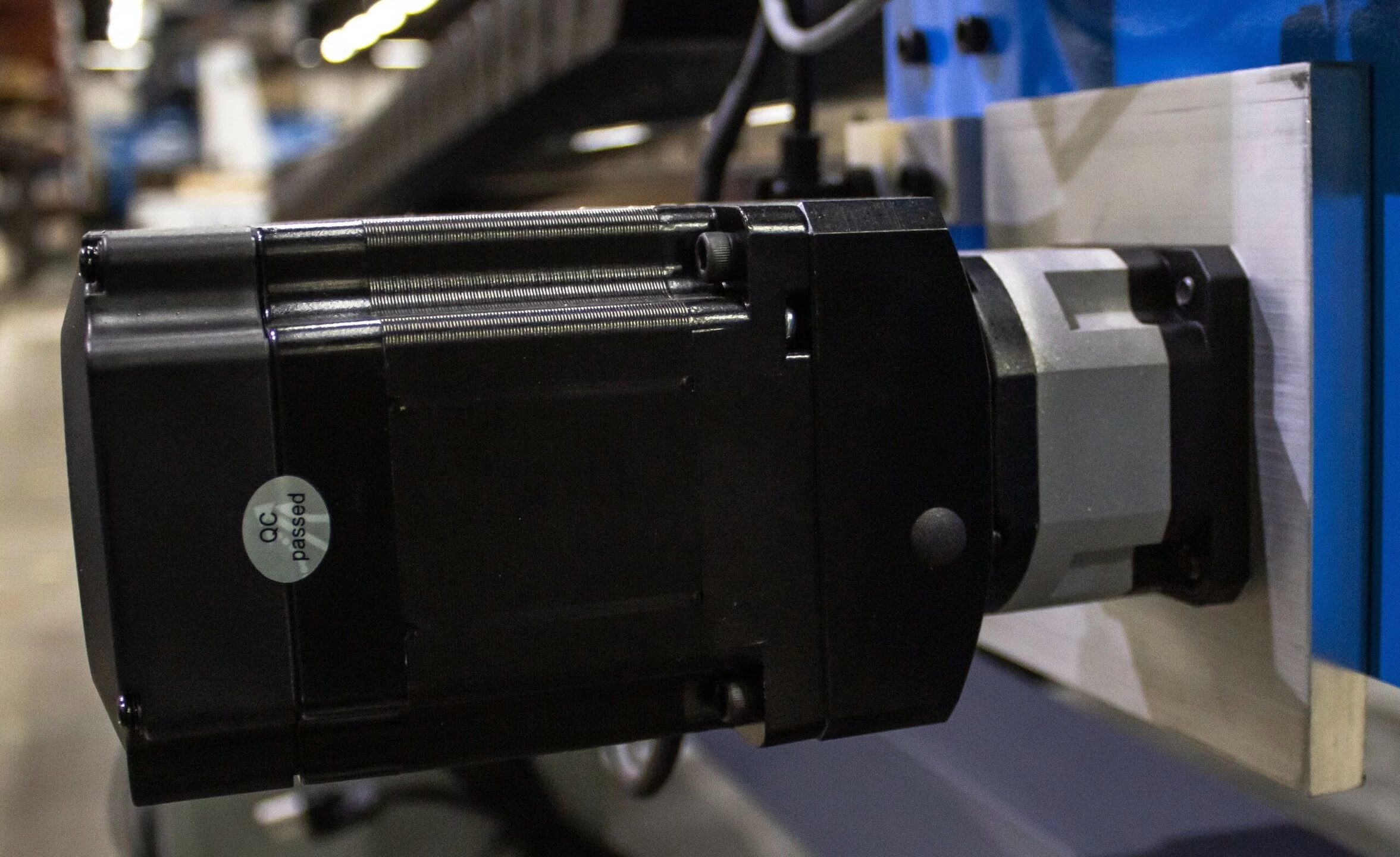

Closed Loop Motors

ShopSabre SideKick machines come standard with closed-loop motors with encoders for higher speeds, greater accuracy, and reduced maintenance. Self-monitoring encoder technology ensures extreme performance, eliminating missed steps, loss of accuracy, and torque reduction. These motors provide enhanced acceleration and stability, ideal for cutting thin materials, maintaining tighter tolerances, and supporting longer duty cycles.

SideKick CNC Plasma Features

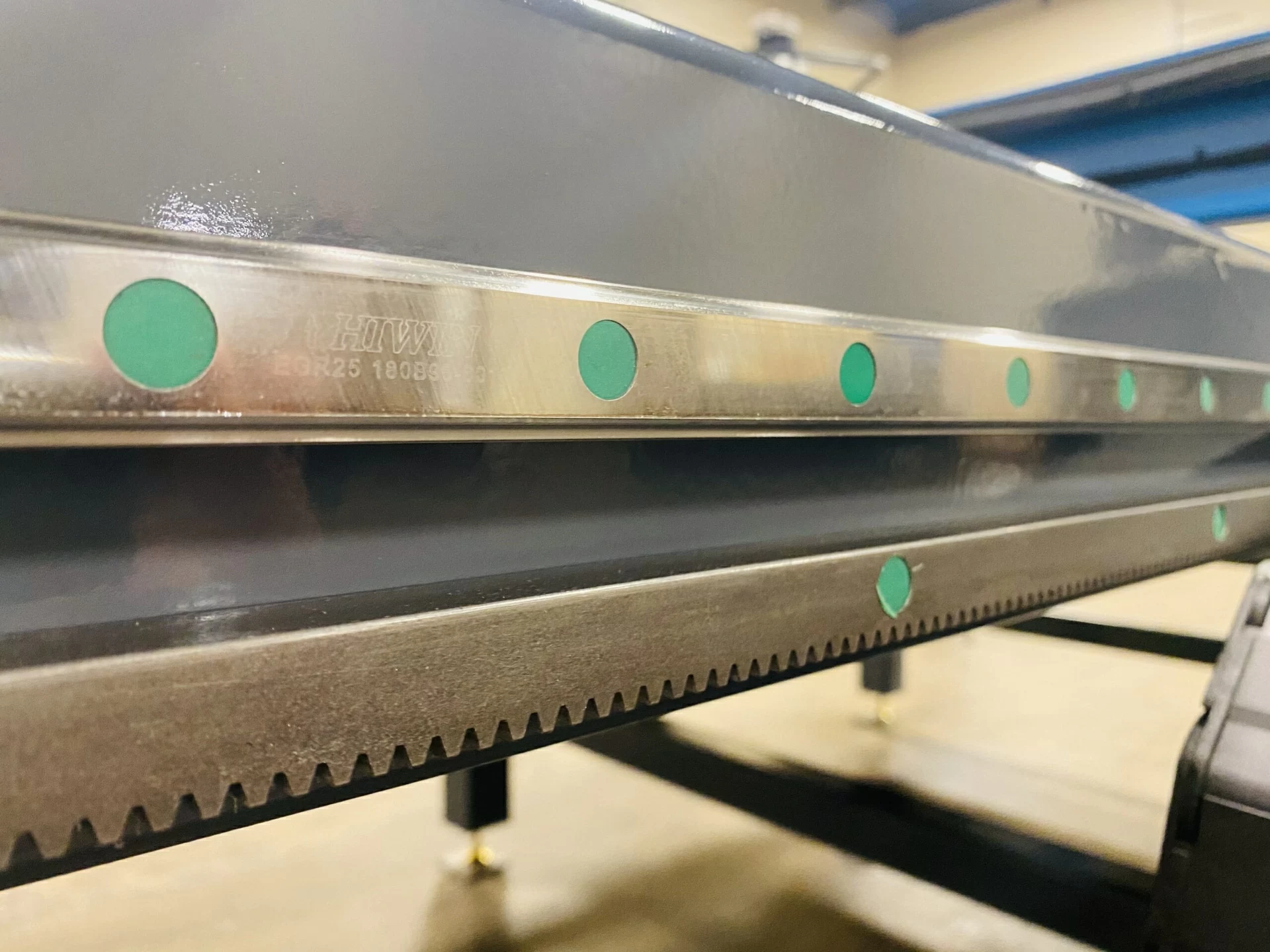

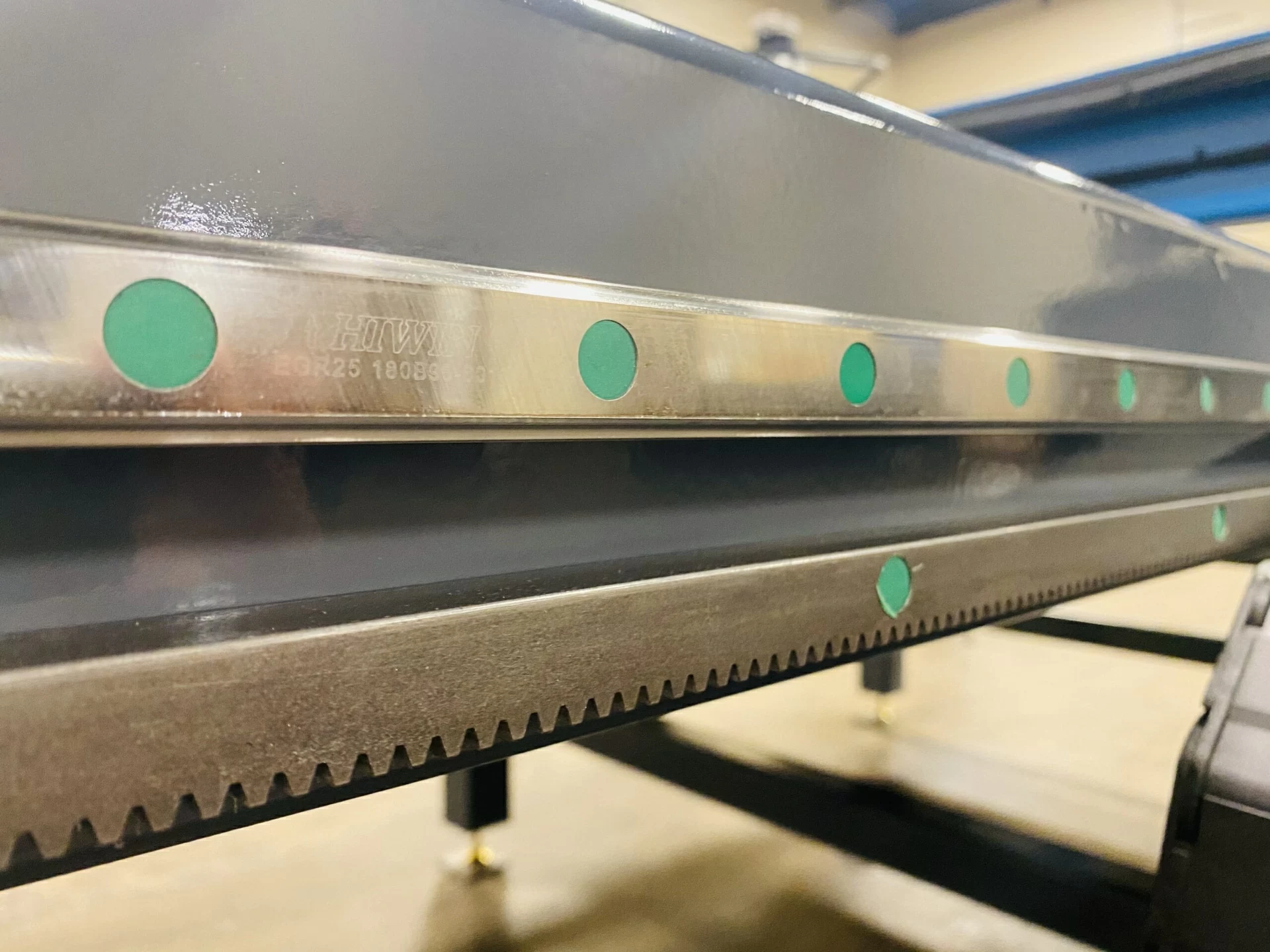

XY Axis Large Rack and Pinion

ShopSabre SideKick Series machines are driven by a large rack-and-pinion XY axis, featuring ShopSabre's exclusive inverted floating drive gear engagement technology. This innovation reduces debris contamination, allows for self-alignment, and extends gear life and performance while reducing maintenance.

SideKick CNC Plasma Features

Aerospace Milling Technology

ShopSabre CNC gantry systems undergo some of the world’s most advanced processes to ensure precision, including the milling of contact surfaces for bearing and rail placement. Since a machine’s accuracy depends on its foundation, the frame of a ShopSabre is built to higher tolerances than the competition.

SideKick CNC Plasma Features

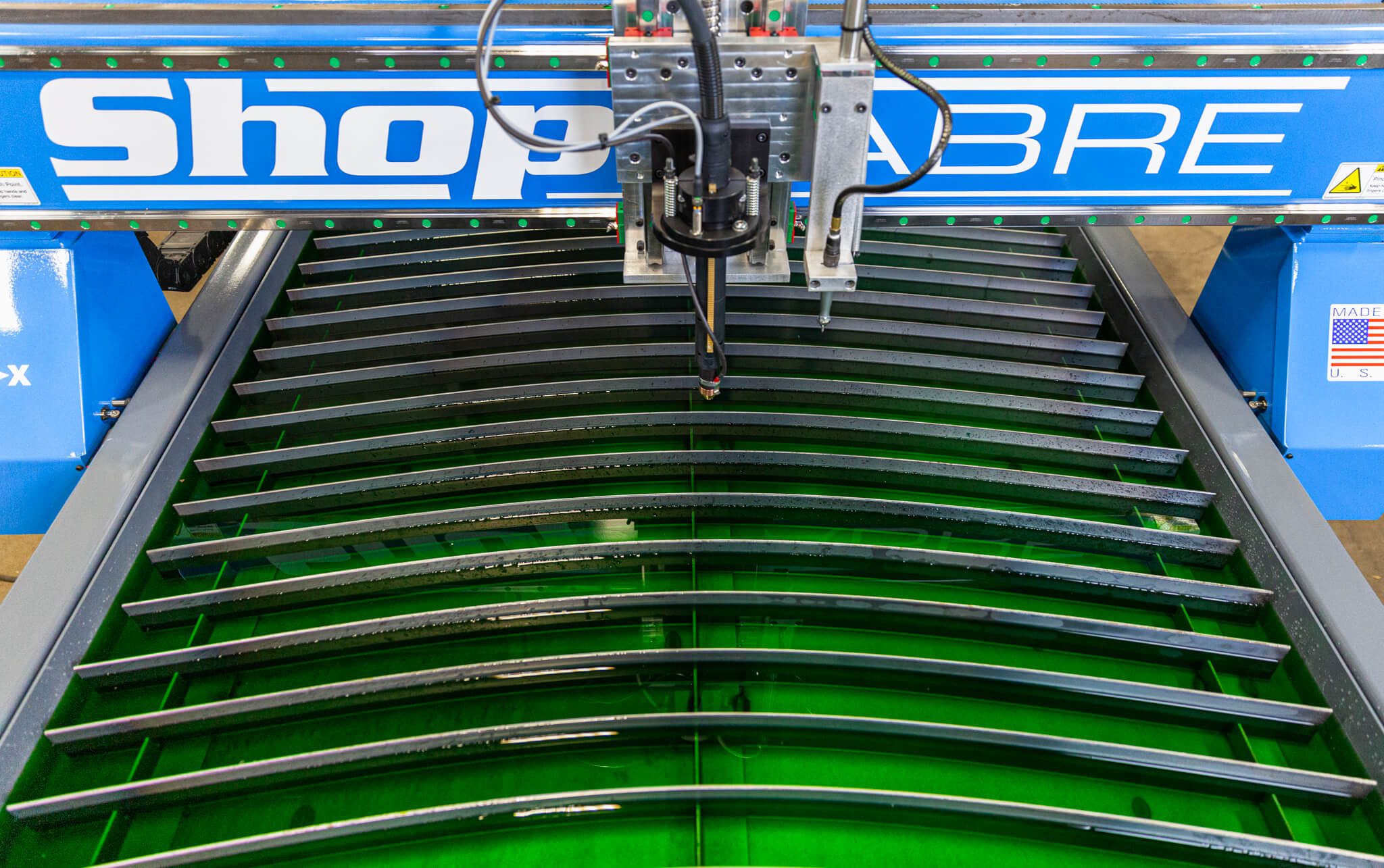

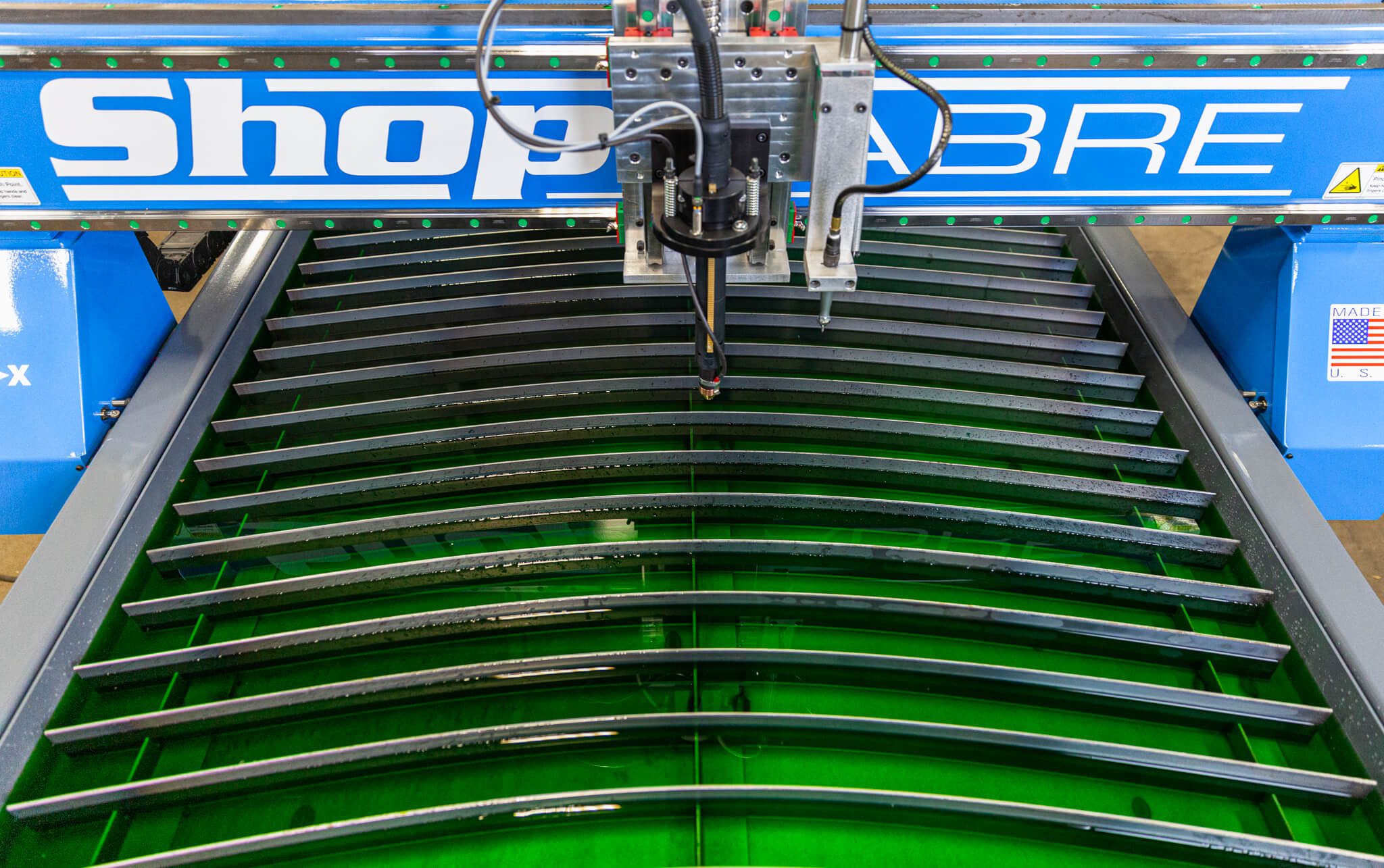

Optional Table

Every SideKick comes with a full bed of slats and the choice of blow-through, down-draft, or water table configurations. *(Note: Down-draft and water tables are additional-cost upgrades.)* Each water table includes a welded pan, water test certification, welded slat brackets, ladder frame bracing, water table isolation diode technology, and Plasma Defense water treatment.

SideKick CNC Plasma Features

Industrial Precision Frame

ShopSabre CNC frames are FEA-engineered and tested, constructed from massive 4x4 structural steel tubes that are welded for added rigidity. Each SideKick Series frame features six legs for increased floor contact and superior vibration control. Each leg is cross-braced and reinforced with steel tubes connecting at least three points, enhancing stiffness and load capacity.

SideKick CNC Plasma Features

Closed Loop Motors

ShopSabre SideKick machines come standard with closed-loop motors with encoders for higher speeds, greater accuracy, and reduced maintenance. Self-monitoring encoder technology ensures extreme performance, eliminating missed steps, loss of accuracy, and torque reduction. These motors provide enhanced acceleration and stability, ideal for cutting thin materials, maintaining tighter tolerances, and supporting longer duty cycles.

SideKick CNC Plasma Features

XY Axis Large Rack and Pinion

ShopSabre SideKick Series machines are driven by a large rack-and-pinion XY axis, featuring ShopSabre's exclusive inverted floating drive gear engagement technology. This innovation reduces debris contamination, allows for self-alignment, and extends gear life and performance while reducing maintenance.

SideKick CNC Plasma Features

Aerospace Milling Technology

ShopSabre CNC gantry systems undergo some of the world’s most advanced processes to ensure precision, including the milling of contact surfaces for bearing and rail placement. Since a machine’s accuracy depends on its foundation, the frame of a ShopSabre is built to higher tolerances than the competition.

SideKick CNC Plasma Features

Optional Table

Every SideKick comes with a full bed of slats and the choice of blow-through, down-draft, or water table configurations. *(Note: Down-draft and water tables are additional-cost upgrades.)* Each water table includes a welded pan, water test certification, welded slat brackets, ladder frame bracing, water table isolation diode technology, and Plasma Defense water treatment.

SideKick CNC Plasma Details

Finance Calculator

Finance Calculator