Description

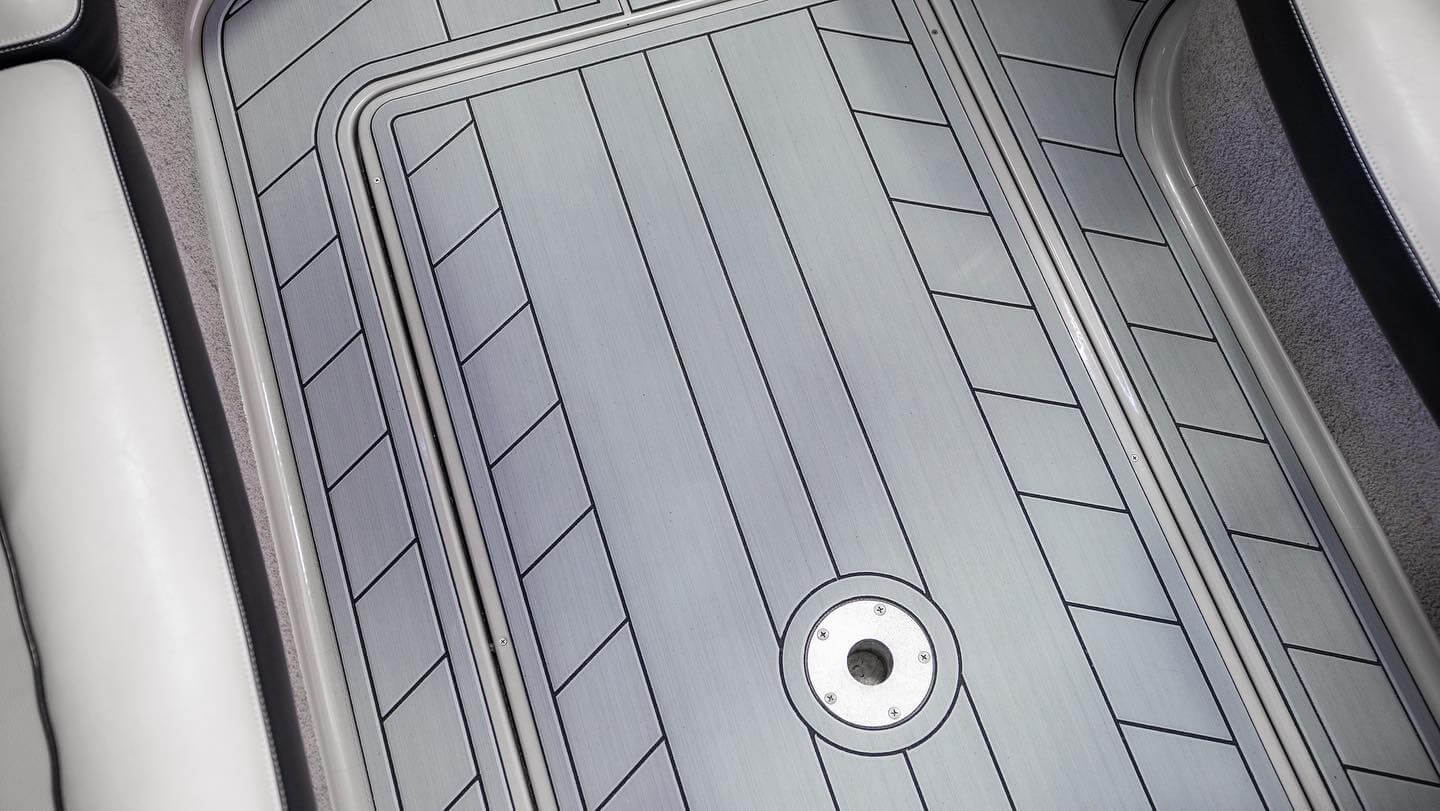

The ShopSabre IS EVA series features an Over-Sized Structural Tube stacked steel one-piece welded frame construction with a massive structural steel tube gantry design. The IS EVA Series was born from necessity and built with a purpose. If you need to tackle Eva Foam / SeaDek material commonly used in the Marine Deck industry look no further. This is the most advanced CNC Router in the price range competing against machines that retail well beyond $100,000.00 but for a fraction of the Price!

Each machine is FEA Engineered, Aerospace Milled, and Laser Calibrated to ensure accuracy and precision from the ground up. Our IS EVA Series CNC router features our Upgraded Stack Steel Construction and comes equipped with the Industries most advanced Drive Technology – Anti-Backlash Ball Screws in all Axis featuring ShopSabre “Whip Free” Technology. The IS EVA Series also comes standard with Advanced AC Digital Servo Motors with matching amplifiers & Glass Encoder Technology. These features improve cutting quality, cutting forces, and overall machine accuracy. Unlike the closest price competitive solutions this machine has absolutely NO rack and pinion drives giving you a clear advantage over the competition. ShopSabre machines are built to outlast and outperform other machines, no matter how much you use your CNC router, you’ll get the precision you need every time from the ShopSabre IS EVA Series. The IS EVA Series comes with an Automatic Tool Changer plus an industrial Tangential Oscillating Knife head with integrated tool & knife measurement for extreme accuracy and unmatched capabilities. If you intend to do EVA Foam or Marine decking, the state-of-the-art IS EVA Series features two sizes built precisely for your needs (4’x8’ or 5’x10’).

Contact us today to learn more about the ShopSabre IS EVA Series CNC routers.

Highlighted Features

- Italian HSD Electric Fan Cooled Spindle available in 1ph. or 3ph. operation with 10HP Auto Tool Changer (ATC) & 12 Tool Positions. (100% Duty Rated)

- Tangential Oscillating Knife System with ShopSabre specific EVA Foam configuration

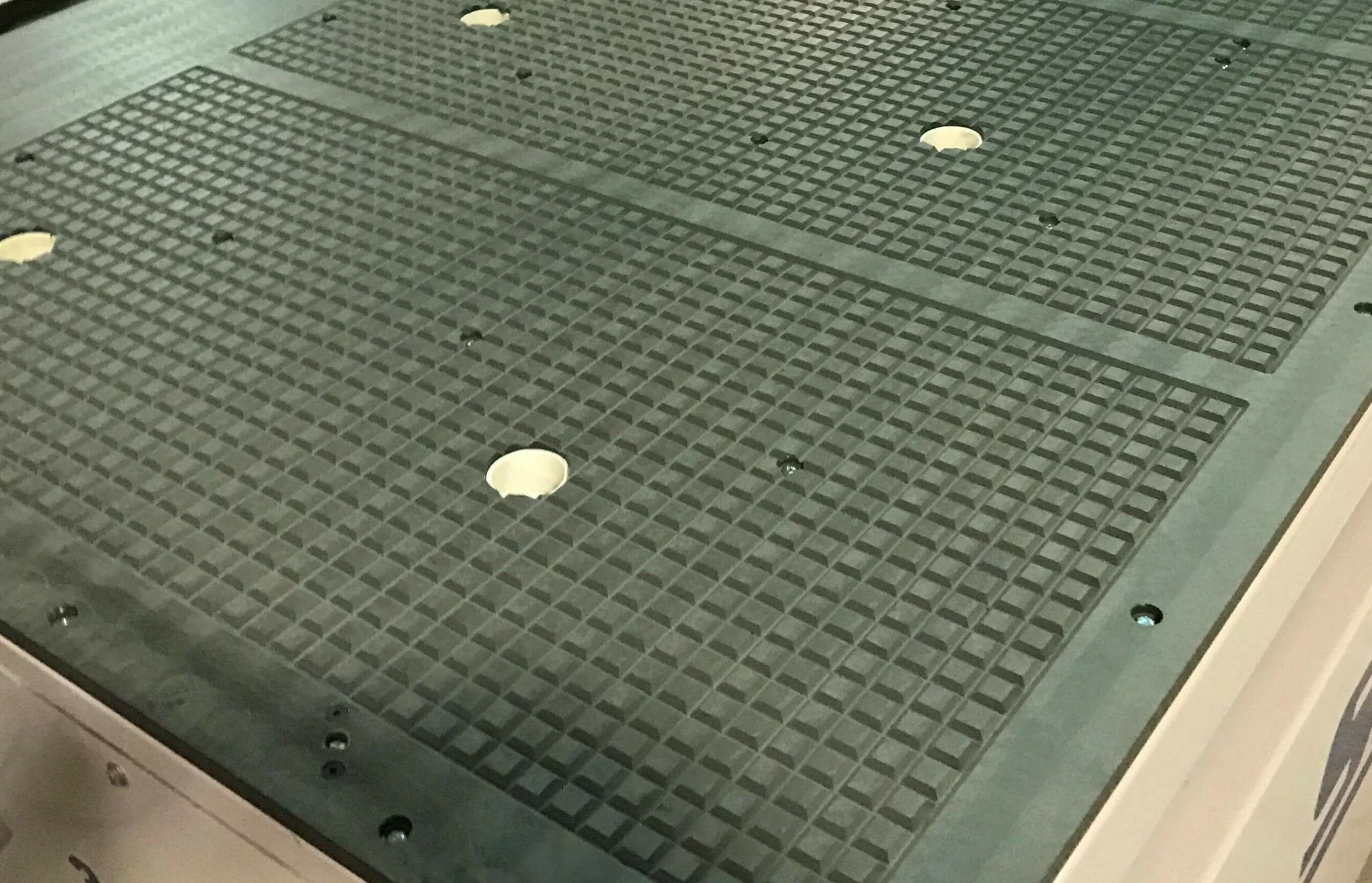

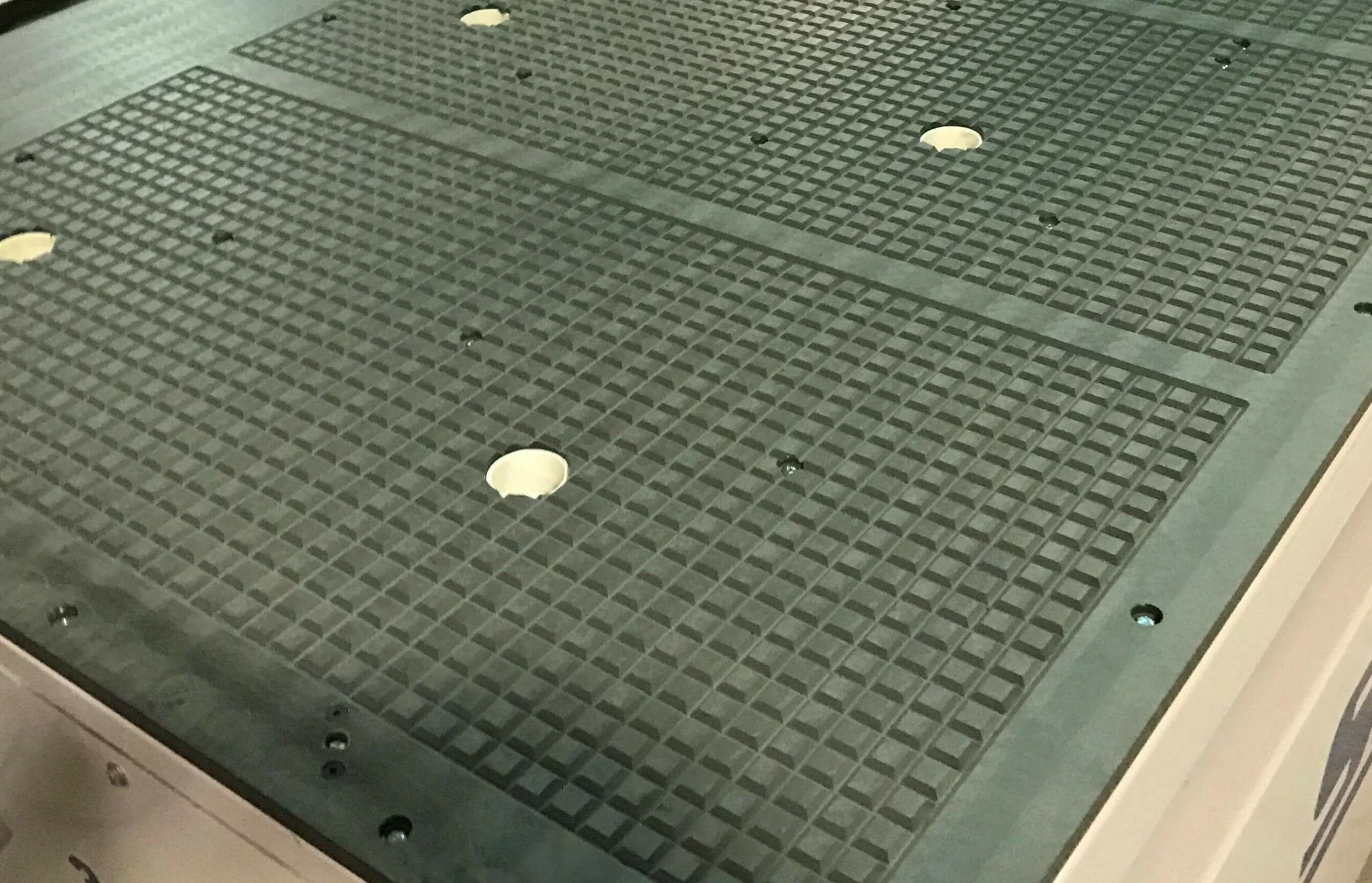

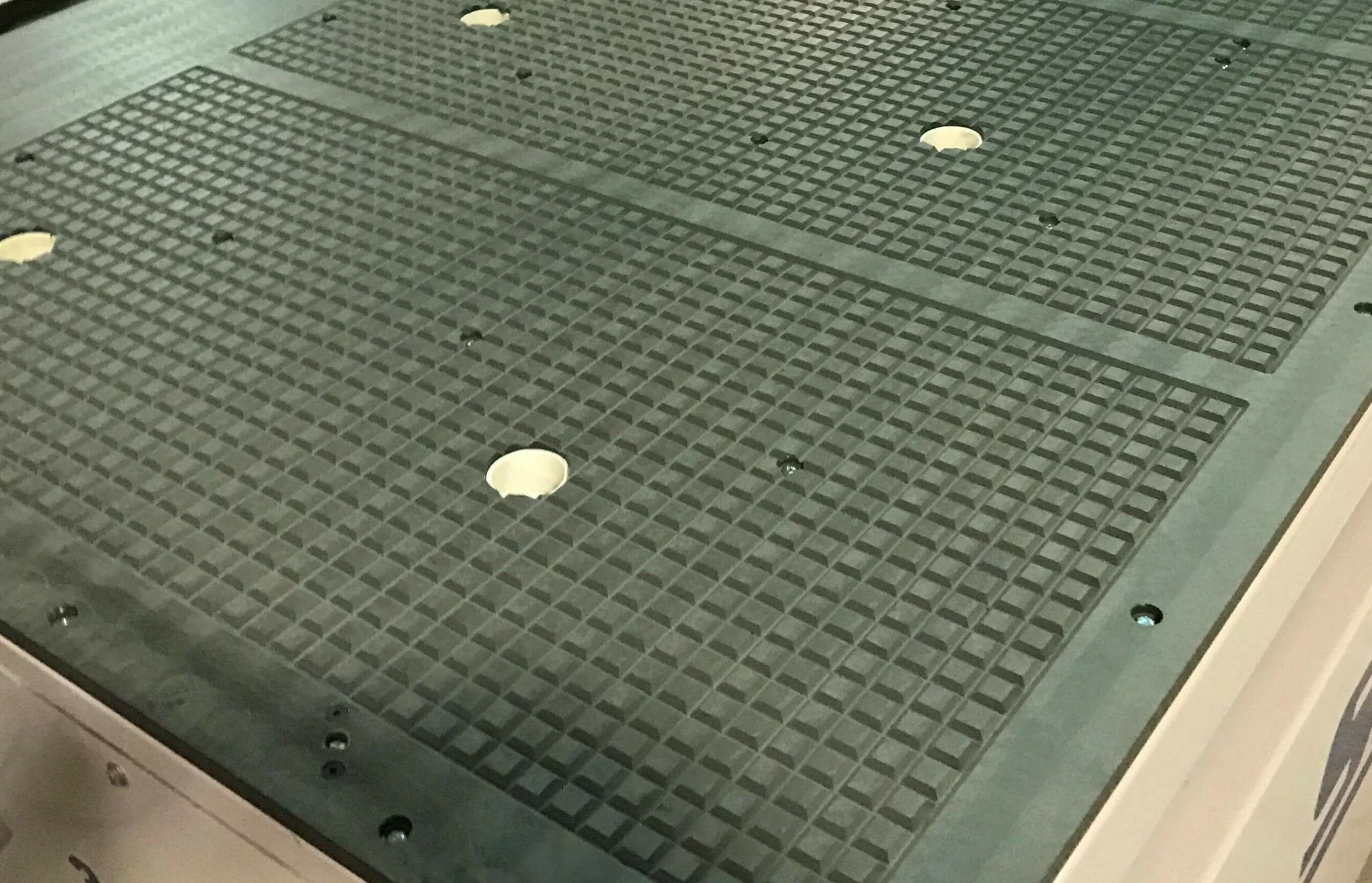

- Phenolic tabletop fastened to structural steel table frame

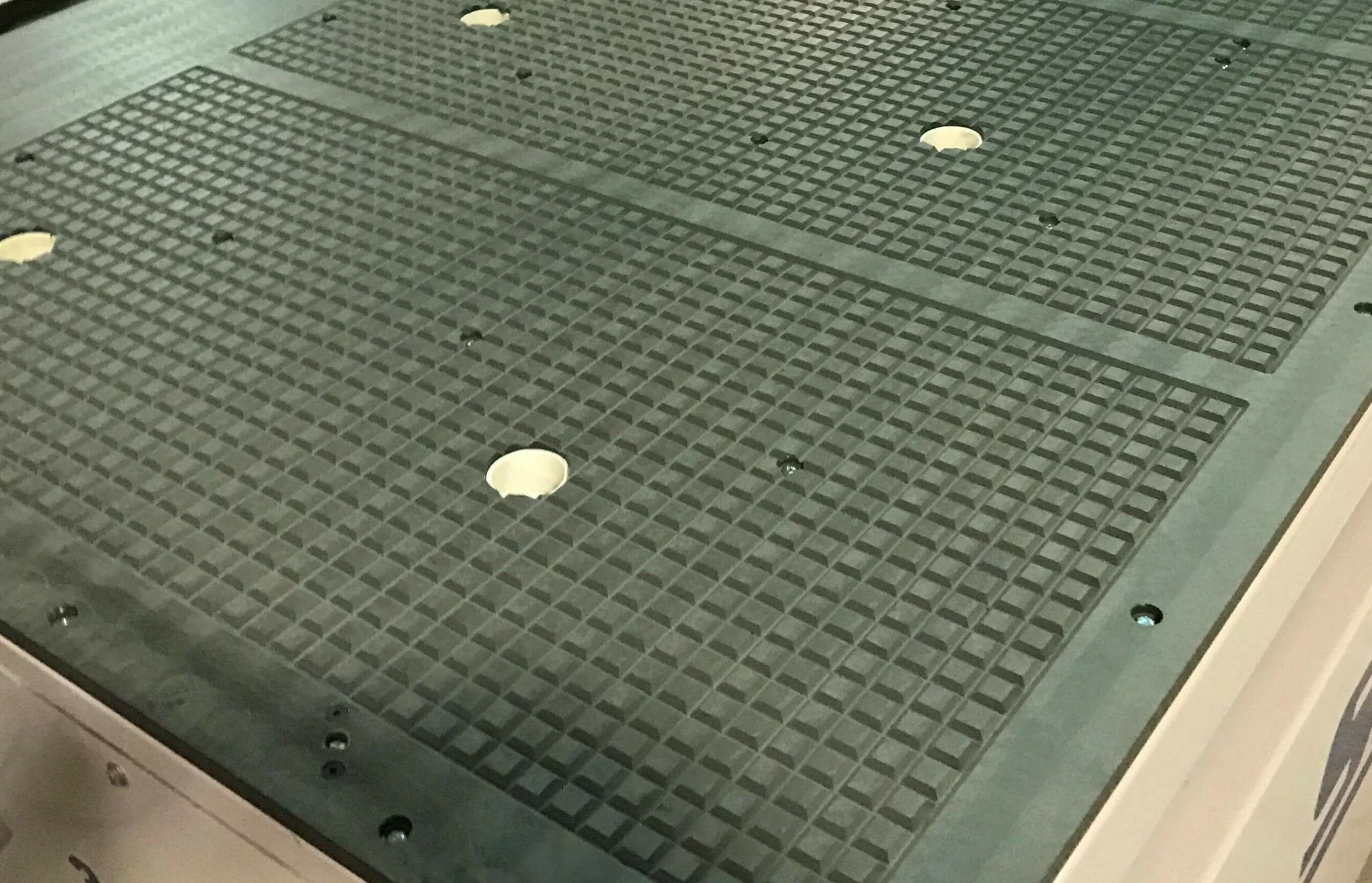

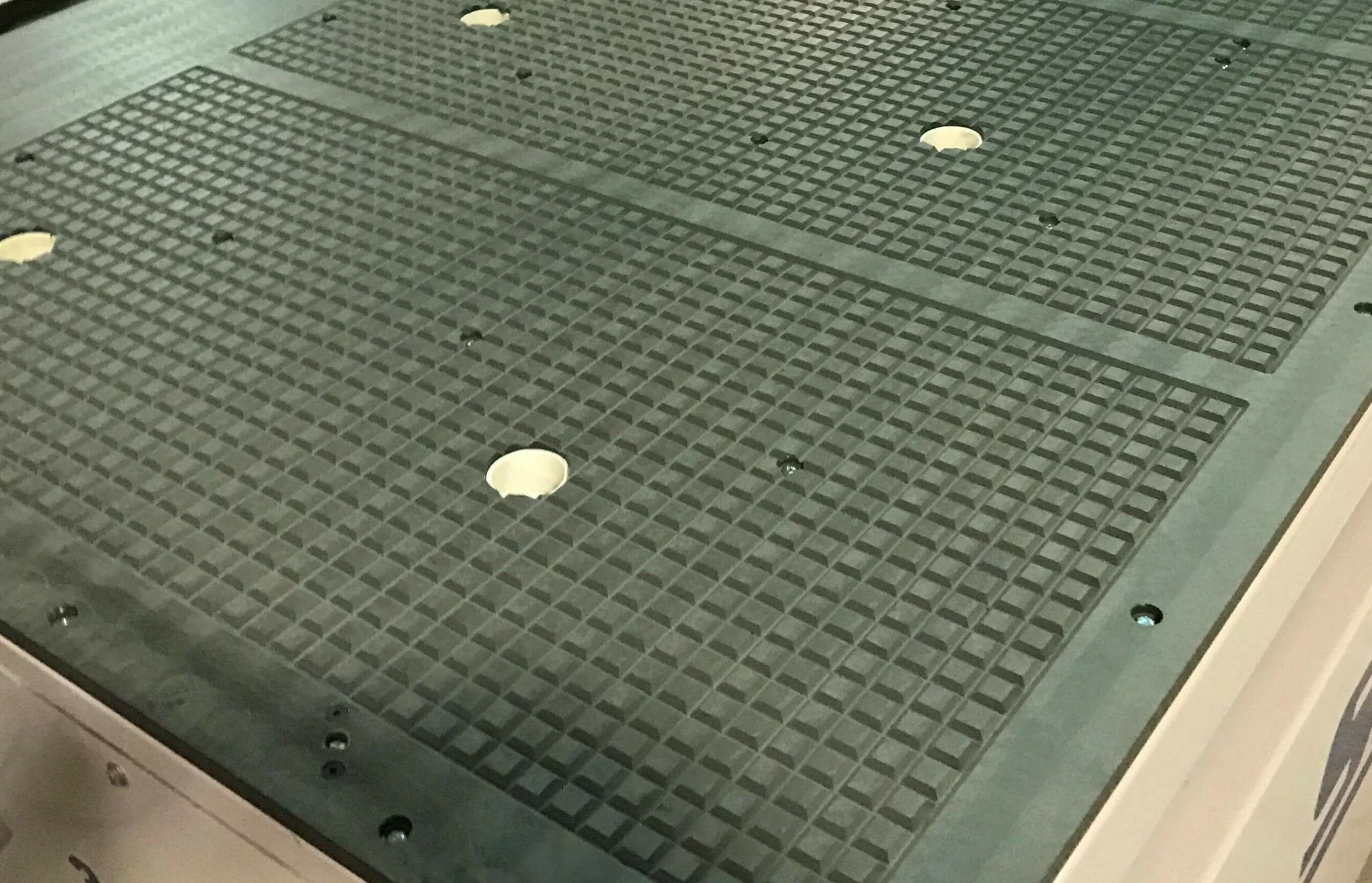

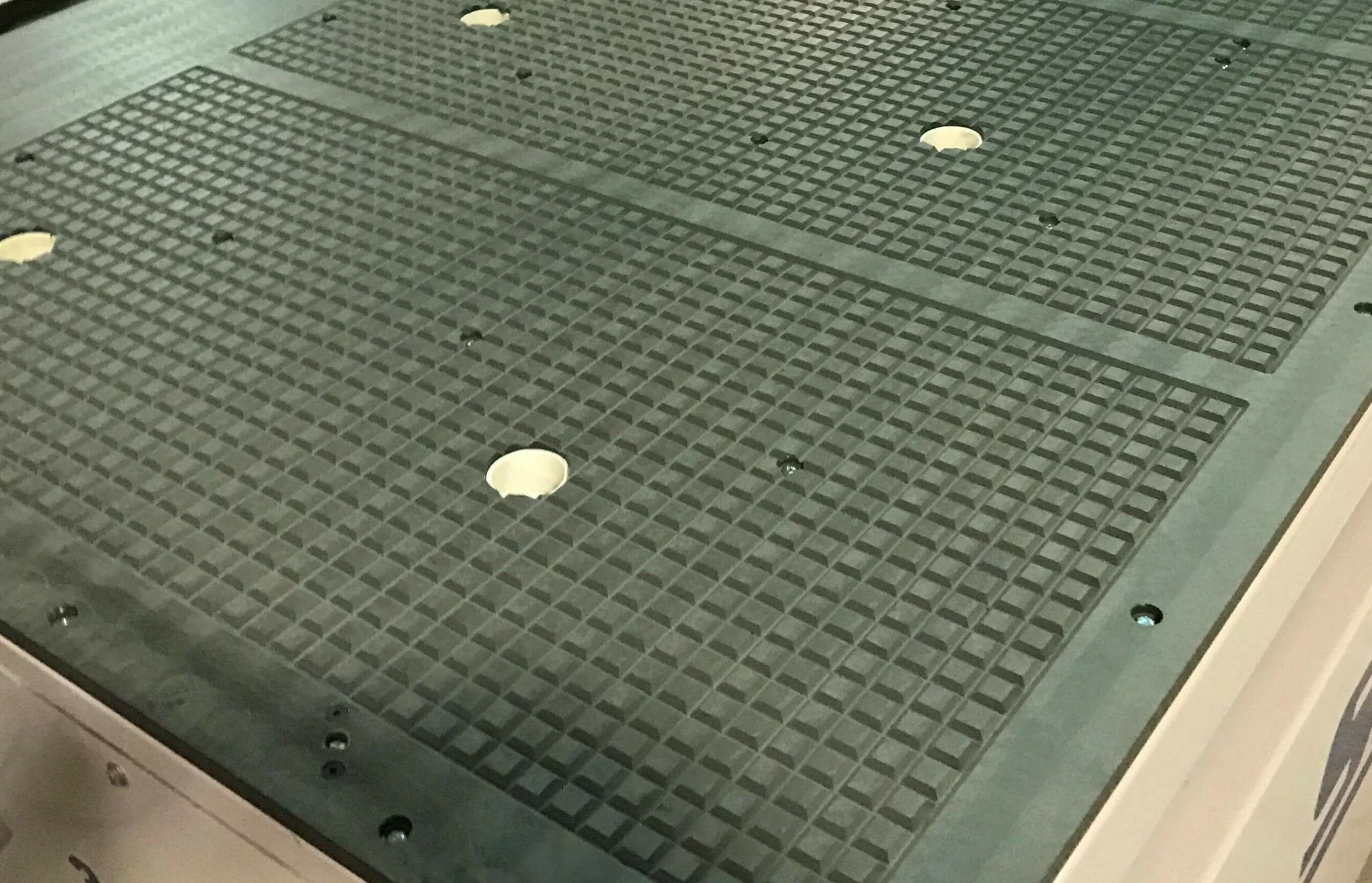

- 4 Zone Vacuum Tabletop with ShopSabre HiFlow Vacuum Technology

- Becker VTLF Series Vacuum Pump (1Phase available by request)

- Table Reference Pins

- ShopSabre tool-free quick release containment dust skirt

- ShopSabre Dual head EVA tool calibration package with incorporation of State-of-the-art Tool Measure Technology Watch our tool measure video!

- Powered 100% by over-sized ball screw drive systems with a Dual Driven Y Axis (Long Axis) and our Anti-Whip Technology Watch our ball screw video!

- Industry Leading Components including Industrial Digital A/C closed loop brushless servo motors with glass encoder technology and individual drive amplifiers with digital tuning Watch our top servo motor technology video!

- Industrial Welded, stress-relieved, and Aerospace milled structural steel tube frame construction.

- Industrial structural steel tube gantry uprights and Steel Cross bridge with Milled Mating Surfaces Watch our steel vs aluminum video!

- High Performance 25MM linear profile guide rails and bearings with Quad Rollers on all axis

- ShopSabre Re-enforced Z Axis Technology with Tool Plate Stiffeners and Super Z Technology!

- Advanced/Smart A/C digital super servo motors with individual amplifiers and glass encoder technology

- Precision linear guide rails and bearings on all axes

- Steel machine operators control stand with casters, computer keyboard tray, mounted emergency stop button, and integrated machine controls with built-in cooling fans and plug and play power connections

- Vectric VCarve PRO CAD/CAM Full License Software

- Easy-to-learn software with point-and-click technology including AT machine CAD/CAM abilities Watch our control screen video!

- At Machine Solid State Hard Drive for Easy Job Storage and Machine dedicated high speed multi-axis controller Technology

- Machine Operator Rolling Control Tower with integrated PC System with full Networking and file management via USB and internet connectivity

- Quick and Effortless Installation Machine Ships Fully Assembled with No Installation Assistance Required!

- ShopSabre CNC name-brand electronics including industrial continuous flex robotic wiring, wire carriers, industrial connectors.

- ShopSabre CNC onboard computer system with integrated WINCNC controller hardware and software

- ShopSabre CNC controller hardware and software with point-and-click technology

- At machine file management with Solid State hard drive

- E-Stop switch

- Limit switches on all three axes

- USB and internet connectivity

- Standard G-code compatible

- Accepts direct dxf import (other various files accepted in CAD/CAM software)

- Free SabreNation Life-Time Tech Support via Phone, Email, and Remote Diagnostic! Watch our support video!

- Free SabreNation Life-time Training and SabreNation University Access!

- Included Complete Warranty

- ShopSabre CNC training (ask for details)

- MADE IN THE U.S.A. American Manufactured & Engineered using FEA Software Watch our engineering video!

IS EVA 408 |

IS EVA 510 |

|

| Footprint | 88" x 133" x 93" | 97" x 156" x 93" |

| Cut Area | 51" x 100" x 12" | 61" x 125" x 12" |

| Z Clearance | 12" standard | 12" standard |

| Z Travel | 16" | 16" |

| Rapid Speed | 2100IPM | 2100IPM |

| Repeatability | +/-.001" | +/-.001" |

| Drive Motors | AC Servo Motors | AC Servo Motors |

| Drive System | Ball Screw X, Dual Y, & Z axis | Ball Screw X, Dual Y, & Z axis |

| Get a Quote | Get a Quote |

Questions?

Not sure which CNC machine is right for you and your production? Schedule a free consultation with one of our in-house experts for personalized, one-on-one guidance.

IS EVA Series Features

Industrial Precision Frame

ShopSabre CNC Frames are FEA Engineered and Tested constructed from Massive 14x10 Steel Tubes which are Stacked and Welded for added rigidity giving you more floor contact and better vibration control. Internally the large tubes are also cross braces and stiffened to increase the rigidity!

IS EVA Series Features

Aero Space Milling Technology

ShopSabre CNC Frames are Run through some of the worlds most advanced processes to assure they are accurate including Precision Milling of contact surfaces for Bearing & Rail Placement along with Ball Screw Mounts. A machine can only be as accurate as its foundation so the Frame on a ShopSabre is built to a tolerance above the competition.

IS EVA Series Features

Ball Screw Technology

ShopSabre IS Machines come standard with 3 Axis Ball Screw Drives with Y Axis (Long Axis) providing Twin Screws to give you 7 times more rigidity than competing machines and unprecedented performance. Ball Screw Technology used at ShopSabre is the latest in the Industry including which gives you less backlash than Rack and Pinion and thanks to our Whip Free Technology it increases the cutting accuracy and gives you superior edge finishes Ball Screw Technology will outlast most comparable machines by as much as 3 to 4 times longer with very little maintenance required.

IS EVA Series Features

Vacuum Performance

The Vacuum Option on the ShopSabre IS Series gives you quick and easy zone control with integrated hard pipe connection for increased air flow and the reserve tank built into the frame to assure your vacuum stays consistent!

IS EVA Series Features

HiFlow Vacuum Technology

ShopSabre CNC HiFlow Vacuum Technology increases the surface flow by as much as 50% over the competition which in the end results in higher holding pressures and power and better performance. Each Vacuum table on the IS Series comes Milled from the factory by your machine cutting head reducing the needs for gaskets and bolts to hold your spoil board down and our exclusive HiFlow Grid makes nested manufacturing a breeze.

IS EVA Series Features

Industrial Precision Frame

ShopSabre CNC Frames are FEA Engineered and Tested constructed from Massive 14x10 Steel Tubes which are Stacked and Welded for added rigidity giving you more floor contact and better vibration control. Internally the large tubes are also cross braces and stiffened to increase the rigidity!

IS EVA Series Features

Aero Space Milling Technology

ShopSabre CNC Frames are Run through some of the worlds most advanced processes to assure they are accurate including Precision Milling of contact surfaces for Bearing & Rail Placement along with Ball Screw Mounts. A machine can only be as accurate as its foundation so the Frame on a ShopSabre is built to a tolerance above the competition.

IS EVA Series Features

Ball Screw Technology

ShopSabre IS Machines come standard with 3 Axis Ball Screw Drives with Y Axis (Long Axis) providing Twin Screws to give you 7 times more rigidity than competing machines and unprecedented performance. Ball Screw Technology used at ShopSabre is the latest in the Industry including which gives you less backlash than Rack and Pinion and thanks to our Whip Free Technology it increases the cutting accuracy and gives you superior edge finishes Ball Screw Technology will outlast most comparable machines by as much as 3 to 4 times longer with very little maintenance required.

IS EVA Series Features

Vacuum Performance

The Vacuum Option on the ShopSabre IS Series gives you quick and easy zone control with integrated hard pipe connection for increased air flow and the reserve tank built into the frame to assure your vacuum stays consistent!

IS EVA Series Features

HiFlow Vacuum Technology

ShopSabre CNC HiFlow Vacuum Technology increases the surface flow by as much as 50% over the competition which in the end results in higher holding pressures and power and better performance. Each Vacuum table on the IS Series comes Milled from the factory by your machine cutting head reducing the needs for gaskets and bolts to hold your spoil board down and our exclusive HiFlow Grid makes nested manufacturing a breeze.

IS EVA Series Details