Machining Aluminum and Using a CNC Machine for Brass

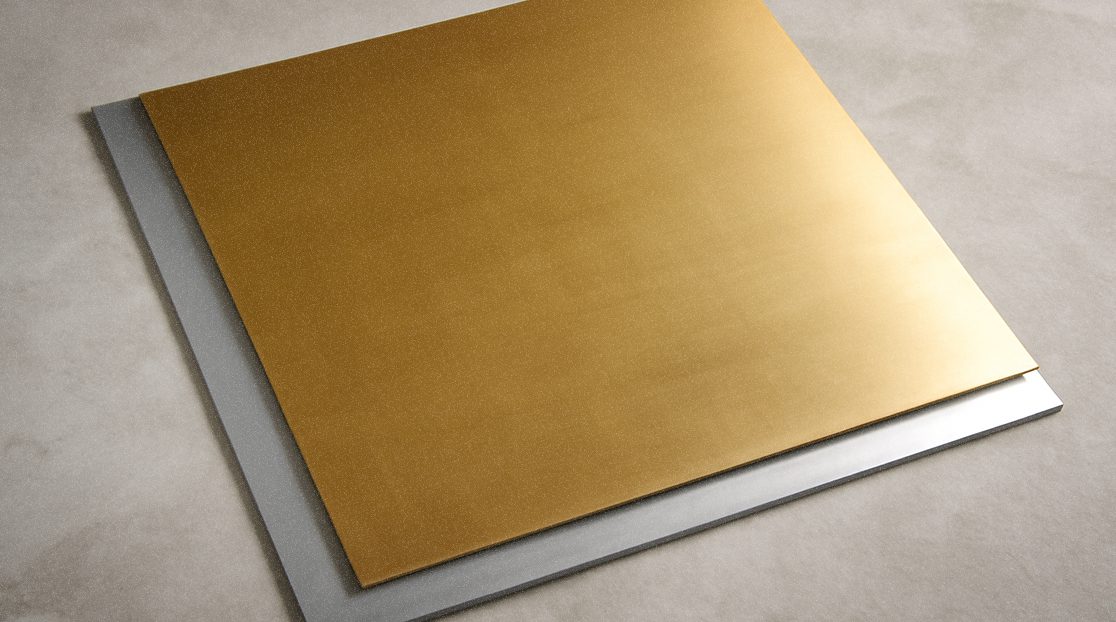

CNC machines provide increased productivity and efficiency in a wide range of applications for hobbyists and professional tradesmen. One of the most popular and practical uses of CNC machines is working with aluminum and brass CNC, where the added capability and precision allow complex work to be completed on an accelerated timeline without sacrificing quality.

In some instances, you may not have a choice as to what material you work with, but if you do, aluminum and brass are both great options for several reasons. Here are some key points to know when using a CNC machine to machine aluminum and brass, whether at home or in a professional shop.

View our collection of CNC Routers and CNC Plasmas at ShopSabre!

Aluminum

Aluminum is a relatively soft yet durable material that is lightweight and malleable. It is non-magnetic, meaning it doesn’t easily ignite, and is a popular choice for creating prototypes because of its flexibility and durability.

However, it does tend to stick to the edge of the cutting tool, which can degrade the tool’s ability and longevity. This needs to be taken into account when cutting, as tool material and tool coating can both factor into remedying this issue. You should also be sure you’re clearing chips constantly, as failing to do so can result in the cutter breaking.

CUTTING TIPS FOR CNC MACHINING BRASS

Proper lubrication will help keep chips from sticking to the cutting edges. Using a mister to provide air blast and coolant mist is effective, easy, and inexpensive. You also want to ensure the tool’s core strength is sufficient to withstand the cutting forces without breaking.

It should be noted that aluminum and other metals have a much smaller sweet spot for optimal feeds and speeds than wood or plastic. When using a CNC router to machine aluminum, you’ll also want to use cutters specifically made for aluminum and/or cutters with a small diameter, as this will help bump your RPM.

Brass

Brass is a metal alloy made of copper and zinc and is one of the most highly used materials in the world. Different brass grades have unique properties that make them suitable for various applications. It is also one of the most accessible materials to machines, especially in comparison to aluminum. Where aluminum often sticks to the tool, brass wants to get out of the way.

Yet, U.S. machine shops must utilize brass’s machinability by up to 85 percent. Brass CNC machining is highly efficient due to its low melting point and flow characteristics, making it easy to cast and machine. Machining brass is often used in electrical work, medical, plumbing, and more, but there is room for growth.

Benefits of brass alloy

Brass is inexpensive and durable, resistant to corrosion, and can withstand extreme temperatures. Brass machined parts are known for their low friction, excellent electrical conductivity, and aesthetic appeal. It cuts much more easily with faster speeds and feeds without negatively impacting tool wear, surface finishes, and chip formation.

It is also entirely recyclable, minimizing waste and ensuring you’re making the most of the materials in your shop. Brass is commonly used in musical instruments and in the manufacturing of electrical components due to its high conductivity, making CNC-machined brass an ideal choice for these applications.

Streamline your shop production with ShopSabre for CNC-Machined Brass Parts

ShopSabre delivers the best CNC routers and plasmas in the industry at the best value. Our products are proudly made in the USA and built with top-rated technology to provide a lasting edge in the shop. Get a quote today to start making the most of your operation.