Working with aluminum CNC machines and brass CNC cutters requires equipment designed for precision and power to unlock the full potential of these materials.

Aluminum’s lightweight durability and brass’s exceptional machinability make them indispensable across industries, from aerospace and automotive to architectural and decorative manufacturing.

Choosing the right CNC solution ensures consistent performance, optimized productivity, and superior results in even the most demanding applications.

Why Choose Aluminum and Brass for CNC Machining?

Whether you’re working with lightweight aerospace components or crafting decorative brass fixtures, understanding their distinct advantages is key to achieving superior results.

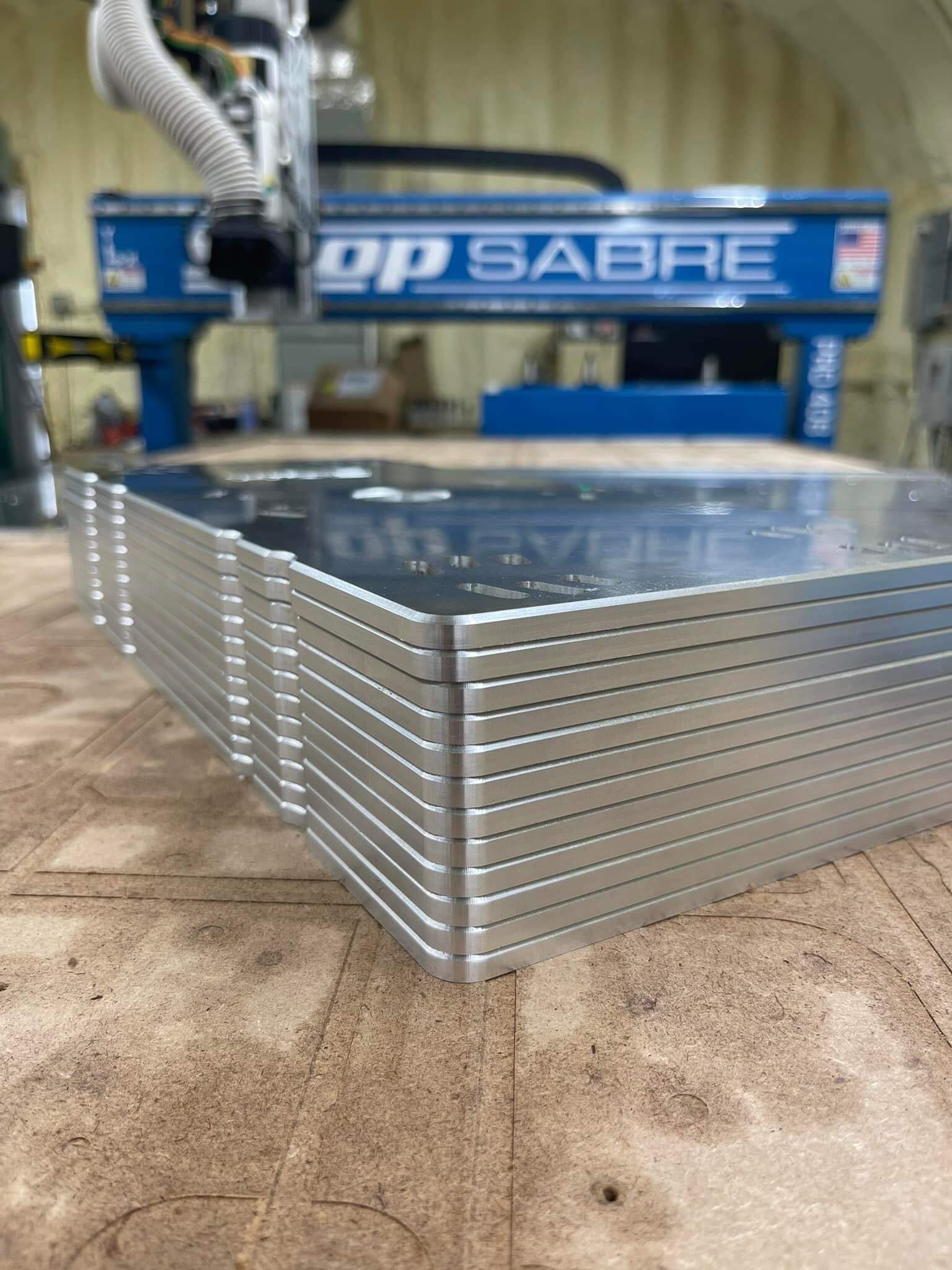

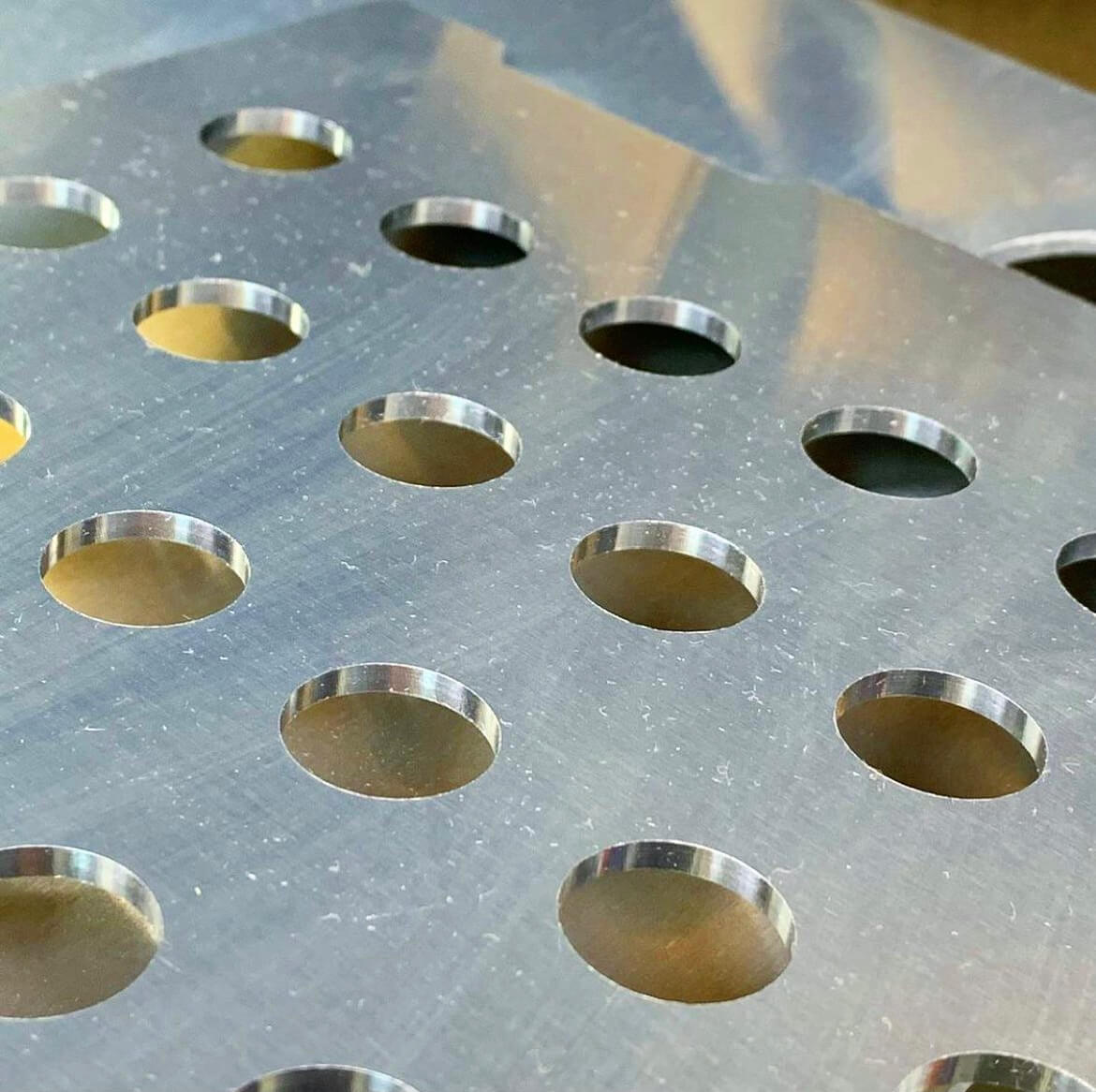

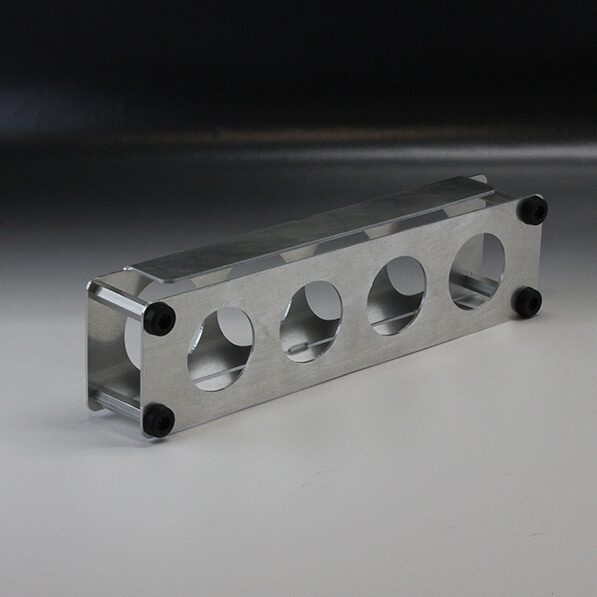

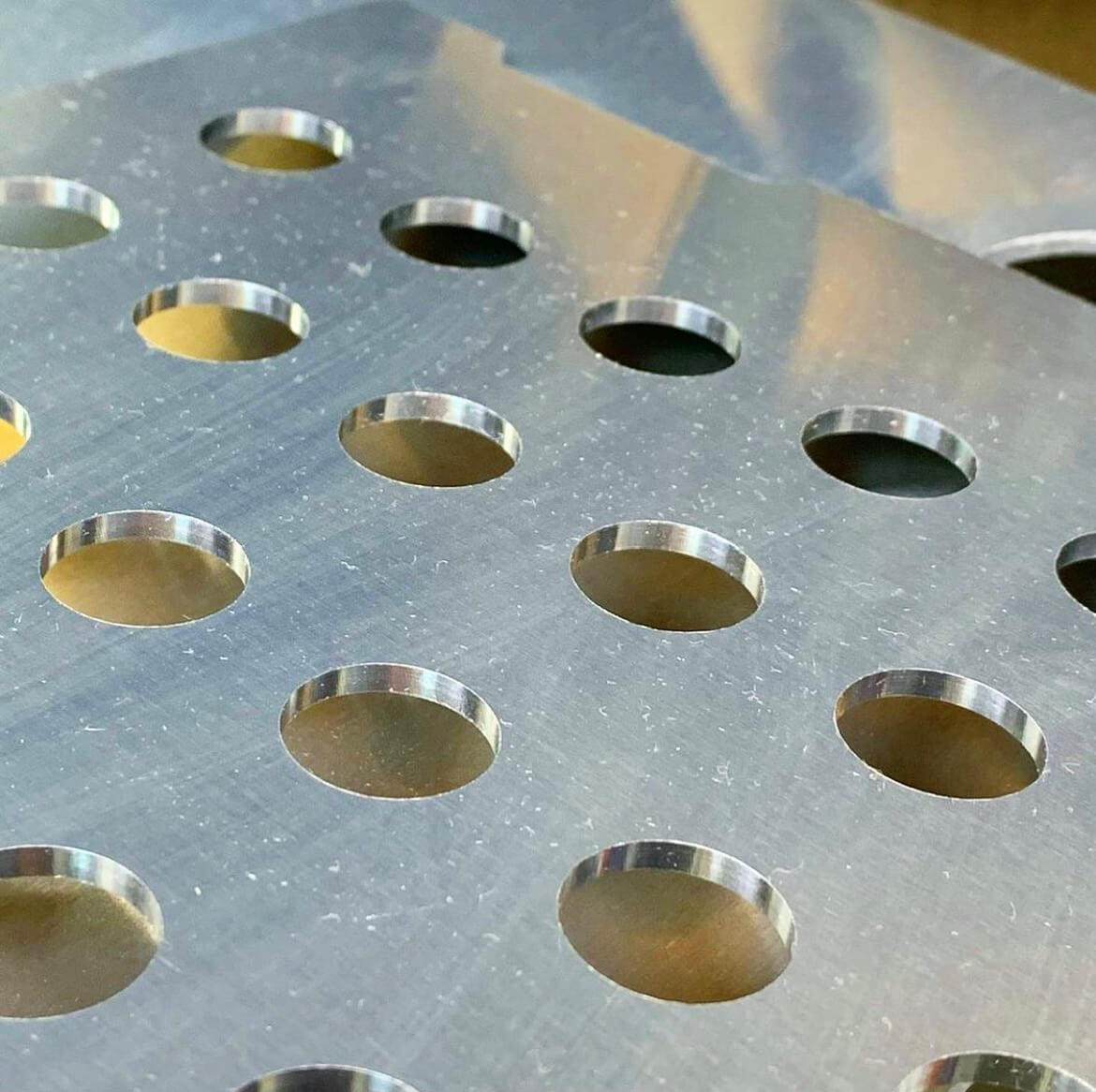

Cutting holes in aluminum with a Shop Sabre Pro 408

The ShopSabre PRO Series delivers the rigidity and precision needed for accurate aluminum and brass machining while maintaining your budget friendly approach. In applications like hole cutting and pattern machining, the PRO Series CNC Router produces clean bores, tight tolerances, and consistent results. With a heavy steel frame and advanced motion control, it enables efficient production and dependable accuracy for non-ferrous metal fabrication.

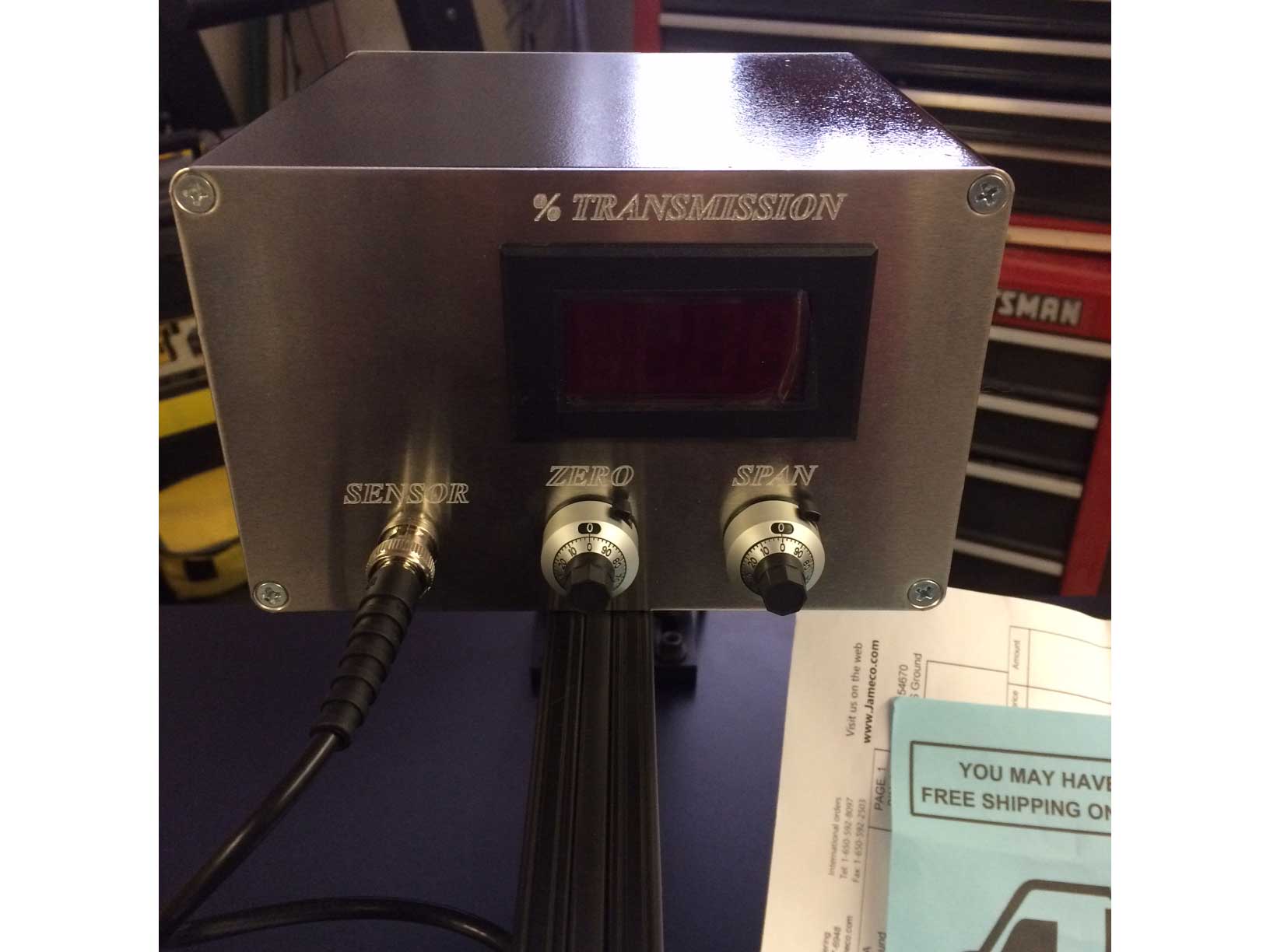

Cutting Out an Aluminum Instrument Panel on a ShopSabre IS Series

The ShopSabre IS Series delivers exceptional rigidity and precision for machining aluminum such as aircraft instrument panels. From clean cutouts and sharp edges to accurate hole patterns, the IS Series produces tight tolerances and consistent results. Built with a heavy-duty steel frame and advanced motion control, it’s ideal for producing high-quality aluminum components in both prototype and production environments.

Making an Aluminum Guitar Case on CNC Router

ShopSabre CNC routers deliver the rigidity and precision required to machine aluminum components for anything from custom fabrication automotive parts to custom guitar cases. From accurate profiles and cutouts to clean edges and consistent fitment, ShopSabre machines handle non-ferrous materials with confidence. Ideal for custom fabrication and small-batch production, ShopSabre enables high-quality aluminum projects with repeatable, professional results.

Aluminum

Lightweight, corrosion-resistant, and highly versatile, aluminum is a go-to material in aerospace, automotive, and manufacturing industries. Using a CNC for aluminum provides the precision needed for tight tolerances and complex shapes while delivering high-quality finishes.

Key benefits include:

- Heat-Treated Grades: Alloys like T651 and T7351 are prized for their strength and durability, making them ideal for structural components, engine parts, and panels.

- Anodizing: Enhances wear and corrosion resistance, ensuring aluminum’s performance in demanding environments such as marine and aerospace applications.

Brass

Brass is renowned for its machinability, natural corrosion resistance, and aesthetic appeal. A brass CNC machine is indispensable for industries requiring high-precision components and decorative elements.

Key applications include:

- Valves and Fittings: Precision machining ensures tight seals and reliable performance in plumbing and fluid systems.

- Decorative Elements: Brass’s malleability allows for intricate designs in architectural and electronic applications.

Aerospace and Automotive

In aerospace and automotive manufacturing, precision is non-negotiable. ShopSabre CNC machines excel in crafting aluminum components like:

- Engine parts: Lightweight yet strong, aluminum engine components reduce vehicle weight while maintaining performance.

- Structural elements: Heat-treated aluminum alloys ensure the durability required for structural integrity in aerospace and automotive frames.

- Panels: CNC routing produces sleek, aerodynamic aluminum panels with consistent quality.

For brass applications, ShopSabre cutters can handle intricate designs and tight tolerances, making them ideal for fuel nozzles, mounting brackets, and decorative accents in luxury vehicles.

Industrial Manufacturing

ShopSabre CNC machines support industrial manufacturers by delivering solutions for producing high-quality brass and aluminum parts.

Common applications include:

- Brass fittings and valves: Brass’s durability and corrosion resistance make it a staple in plumbing, HVAC, and fluid systems. CNC machining ensures these components meet precise specifications for optimal performance.

- Precision-machined components: From signs to gears, ShopSabre’s machines can handle various brass and aluminum routing tasks, even in high-volume production runs.

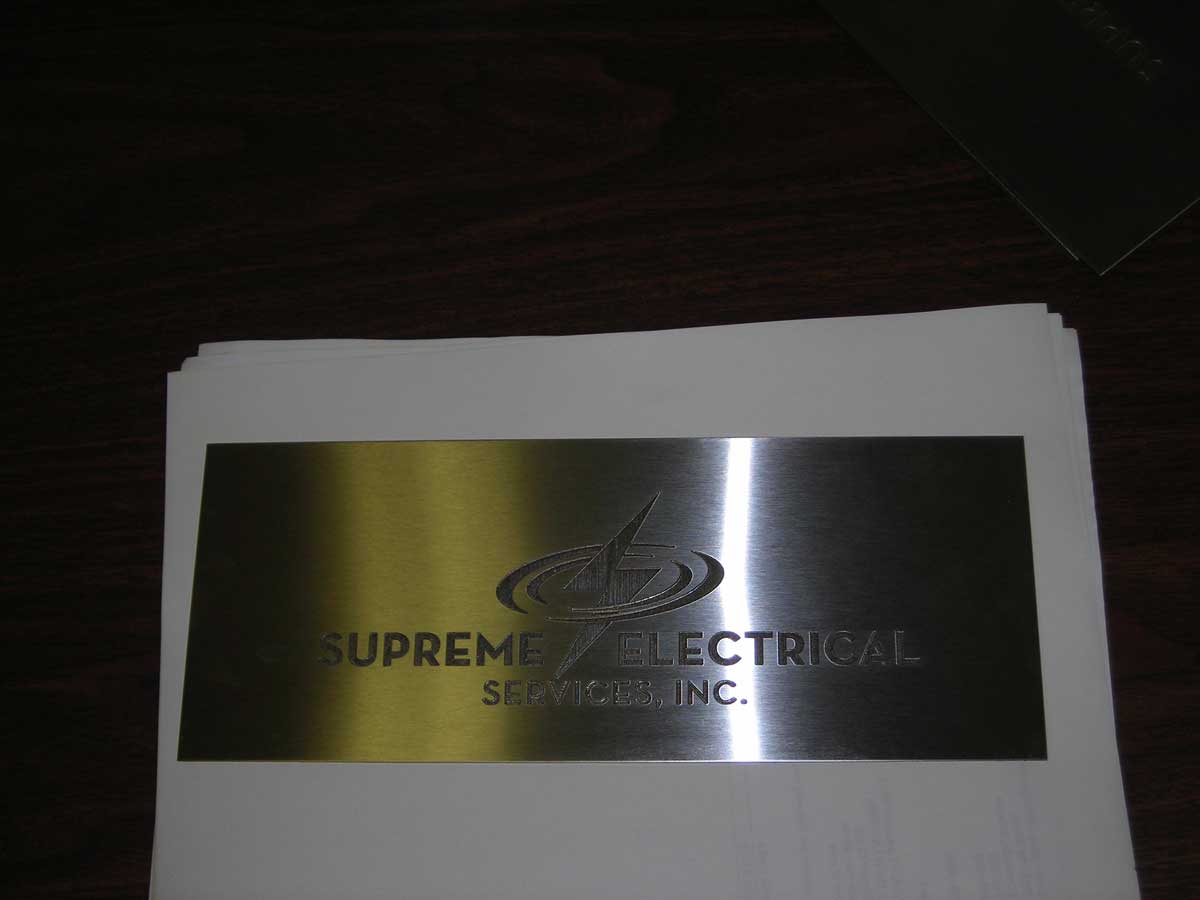

Signage and Prototyping

Custom fabrication demands accuracy, and ShopSabre CNC machines rise to the challenge.

For signage and prototyping applications:

- Aluminum plates: Lightweight and corrosion-resistant, aluminum is perfect for outdoor signage and branding materials.

- Detailed brass designs: ShopSabre’s brass CNC cutters allow for intricate patterns and lettering, making brass an excellent choice for high-end, decorative signage.

The Best CNC Routers for Aluminum & Brass

ISM Series

What It’s Best For: High-performance needs like aerospace-grade aluminum or intricate brass components.

Industrial Series (IS)

What It’s Best For: Large-scale aluminum and brass production tasks requiring durability and speed.

Pro Series

What It’s Best For: Flexible manufacturing of aluminum and brass in small to medium production runs.

ShopSabre 23

What It’s Best For: Entry-level or prototyping needs with aluminum & brass.

Why Choose ShopSabre?

ShopSabre CNC machines are designed specifically to handle non-ferrous metals like aluminum and brass with ease and precision. Their industrial-grade construction and advanced technology make them ideal for tackling the unique challenges posed by these materials, from high cutting forces to maintaining exact tolerances.

ShopSabre CNC machines empower you to achieve outstanding results with efficiency and reliability.

- American-Made Quality: Every ShopSabre machine is designed, manufactured, and supported in the USA.

- Lifetime Support: Get expert guidance at every stage, from setup to production optimization.

- Durable Design: Built to minimize harmonics in the toughest materials with minimal maintenance.

- Heavy-Duty Frames: Robust designs ensure the best performance by reducing vibration & deflection to ensure consistent accuracy, even during extended production runs.

- Advanced Drive Systems: Using the most advanced technology with Ball Screws on our most popular models ensures a smooth, stable, and precise cutting process allowing you to achieve better cutting forces and resulting in more success.

- Carbide Tool Compatibility: Improves finish quality and reduces tool wear, which is especially important for aluminum machining.

- Optimized Motion Control: Proven, precise, repeatable results, even for intricate designs and complex geometries.

- Custom Solutions: Not sure which machine fits your needs? Schedule a free consultation to find your perfect match.

“I’m amazed at how easy the ShopSabre CNC is to use.

“Truly the best American company around… and I mean that!

Expand Your Capabilities with ShopSabre CNC

From creating aerospace-grade aluminum parts to crafting precision brass components, ShopSabre CNC machines deliver the performance you need to stay competitive.

With advanced features, industrial-grade durability, and expert support, our machines ensure that your aluminum and brass machining projects achieve exceptional quality and efficiency.

Ready to Take the Next Step?

Contact us today to explore how a ShopSabre aluminum CNC machine or brass CNC cutter can transform your production capabilities.