Whether you are working with sheets in a high-production setting or one-off parts in a more labor-intensive product, a ShopSabre CNC router has the solution to help increase production while maintaining a favorable budget.

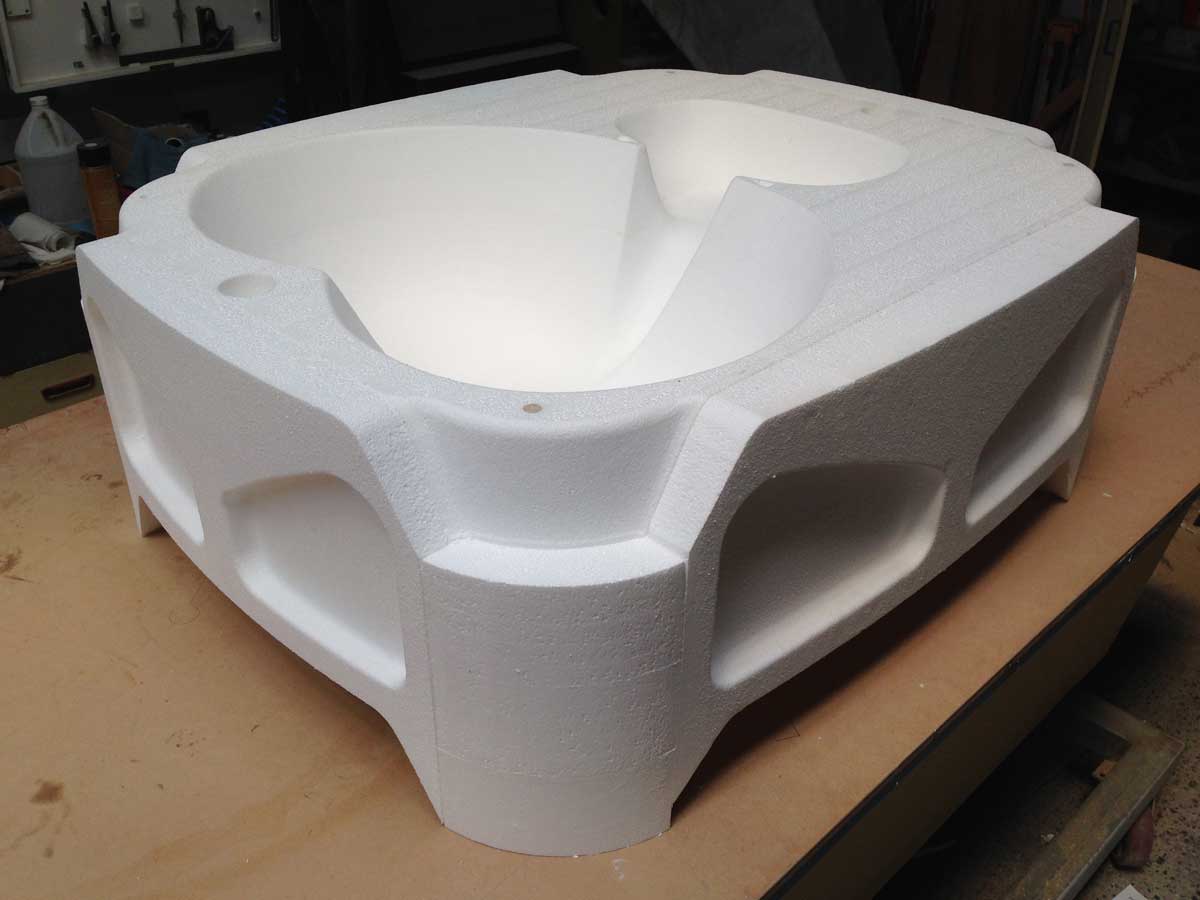

ShopSabre CNC routers enable many manufacturing facilities to produce higher-quality plastic and foam products. Acrylic, also known as PMMA, is one such material that offers high transparency and versatility in various applications.

Don’t outsource your materials when a ShopSabre CNC Router can bring your work in-house and put the dollars back in your pocket! For those looking for a cheaper alternative, materials like certain thermoplastics can provide cost-effective options without compromising quality.

Why Use ShopSabre For CNC Plastic Cutting?

To get precision and accuracy when cutting plastic or foam, you need a machine that doesn’t compromise on quality. Our routers are equipped with an upgraded frame, gantry, and drive system technology to handle a wide range of CNC plastic machining, so you get flawless results every time.

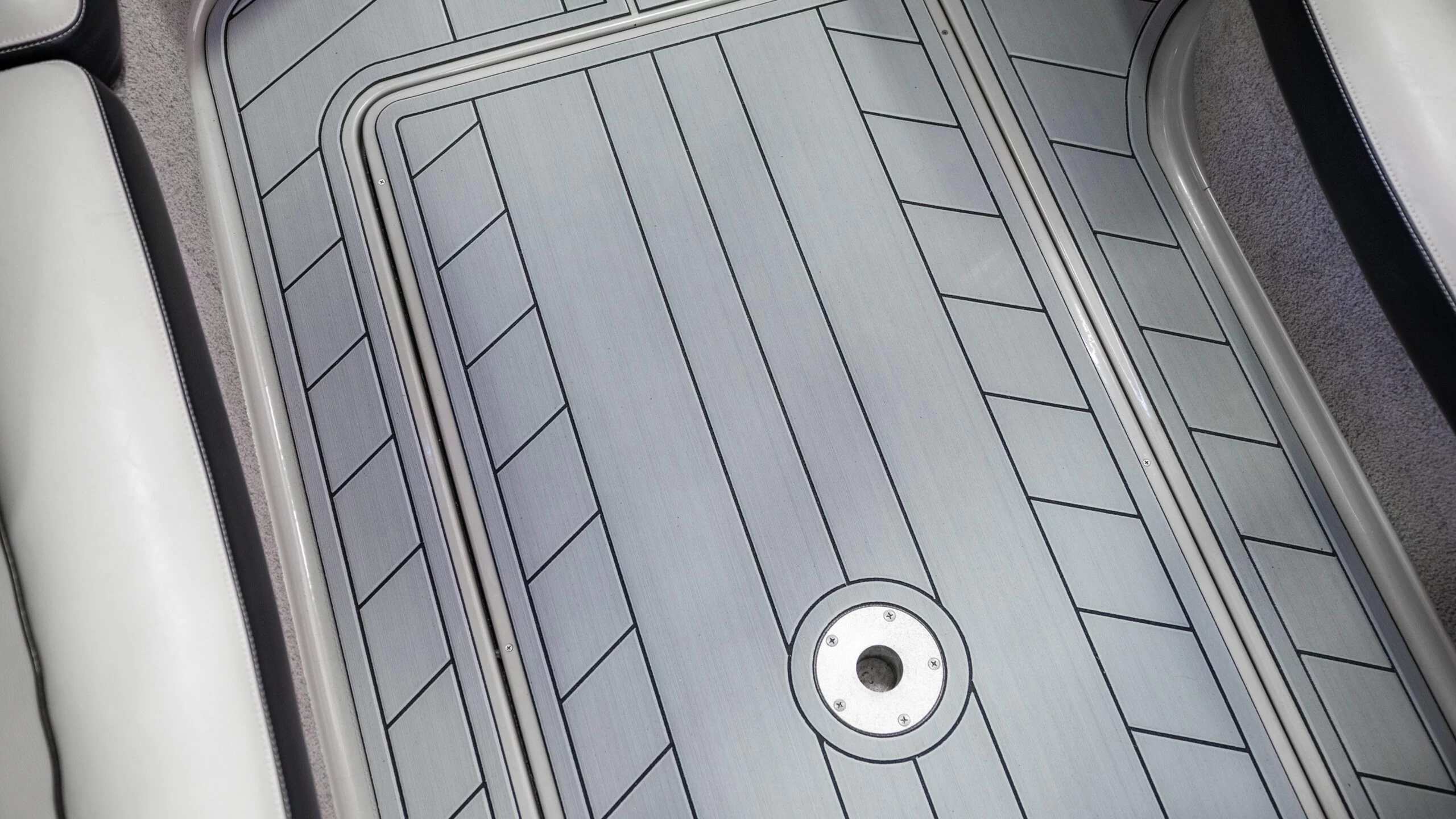

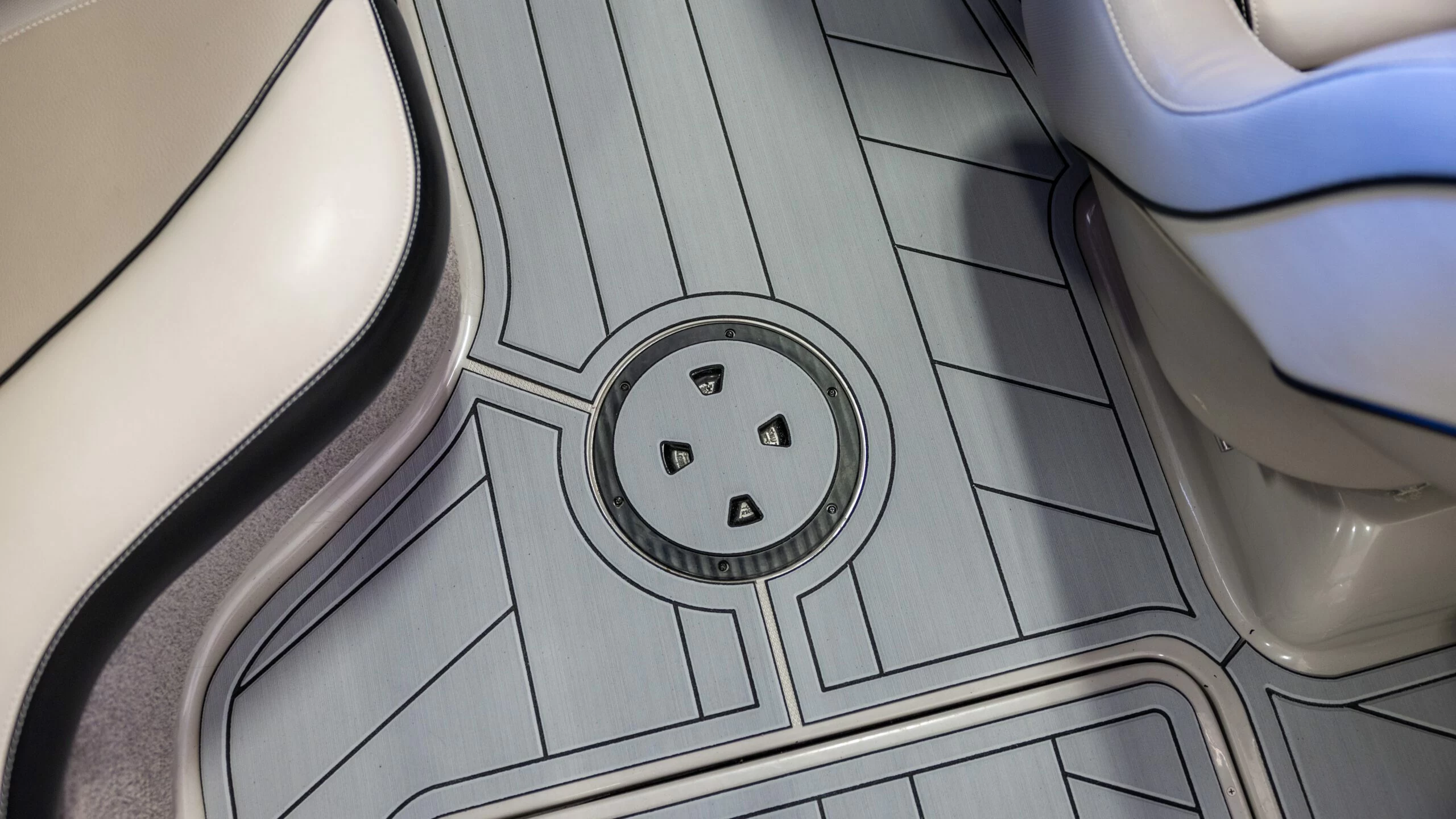

ShopSabre CNC Cutting EVA SeaDek Foam

ShopSabre CNC routers deliver clean, consistent, and repeatable results when cutting EVA foam materials like SeaDek®, making them ideal for both marine and automotive applications. From custom boat decking and swim platforms to automotive flooring, panels, and protective padding, ShopSabre machines provide the precision needed to achieve tight tolerances, crisp edges, and flawless fitment.

ShopSabre CNC systems handle laminated, textured, and adhesive-backed EVA foams with ease—allowing manufacturers and custom shops to scale production while maintaining premium surface quality. Whether prototyping or full-scale production, ShopSabre helps turn high-value EVA foam designs into finished products efficiently and reliably.

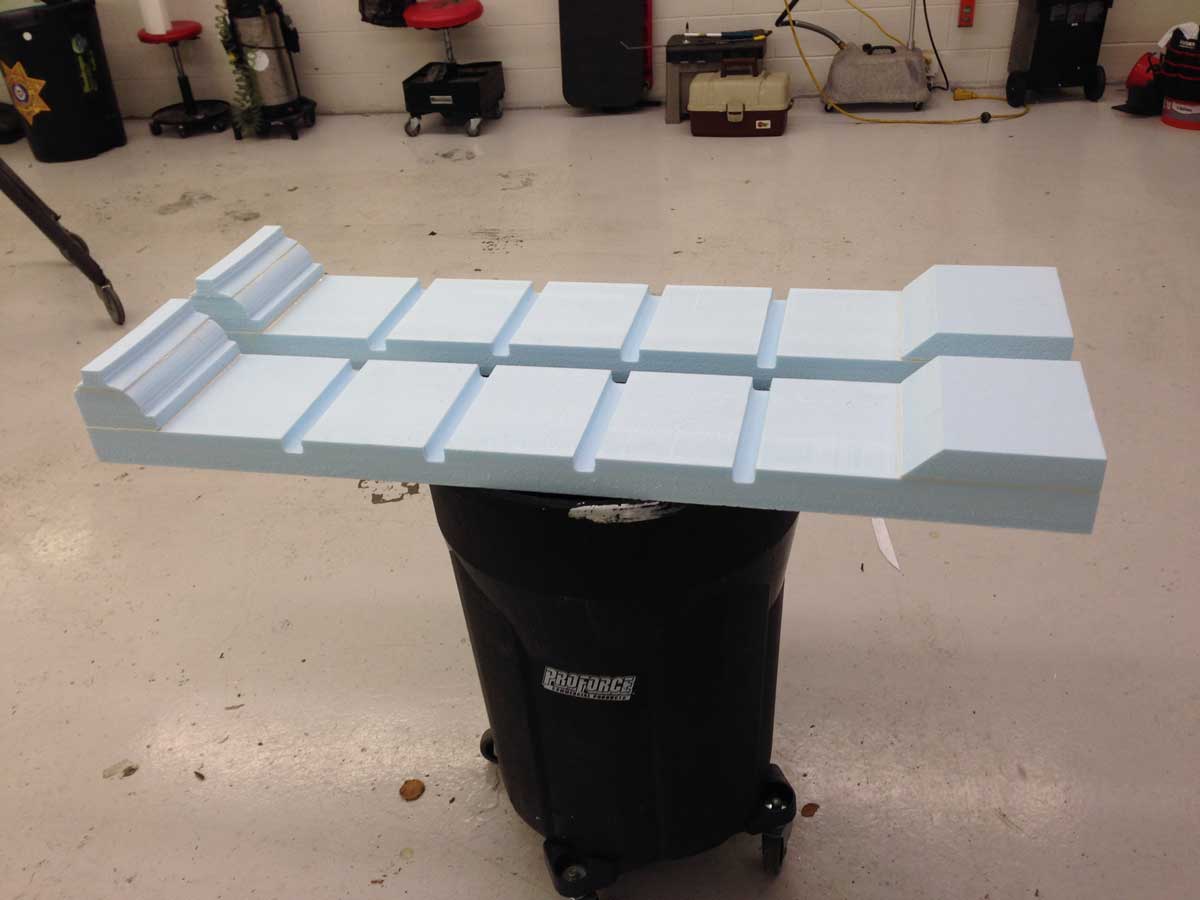

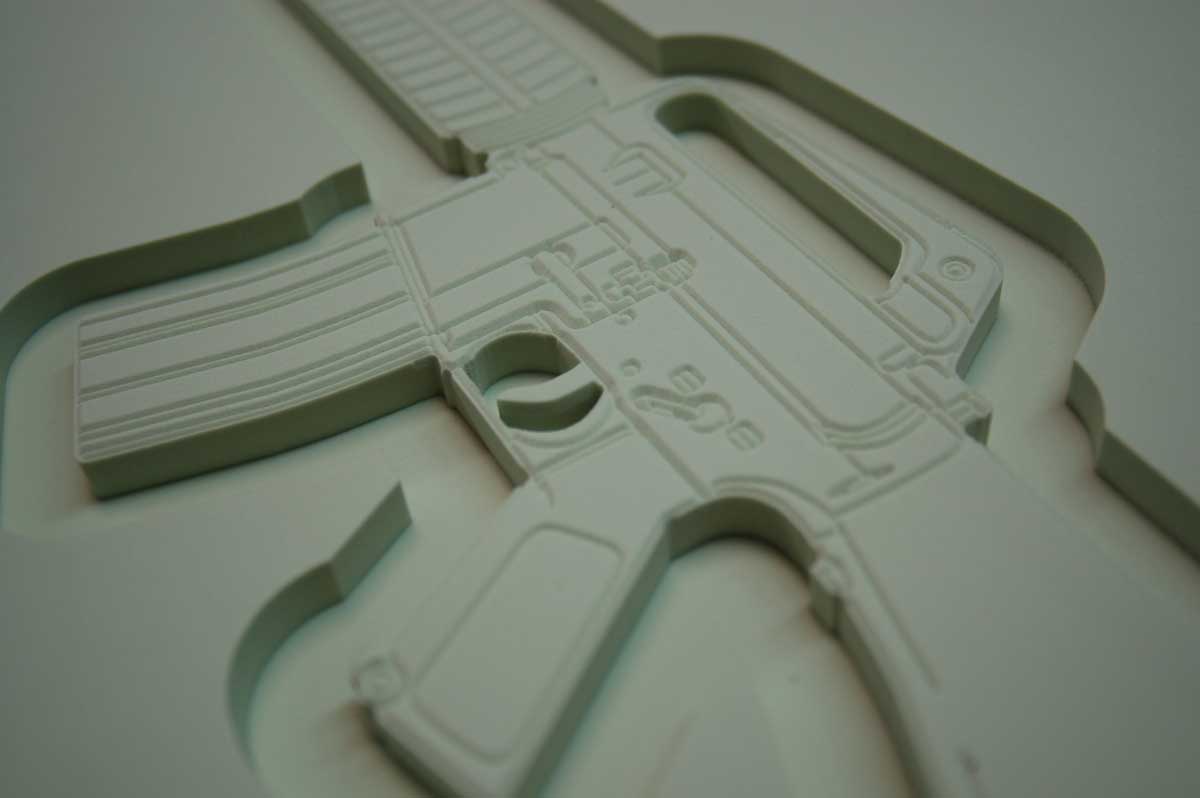

Cutting Toolbox Foam Inserts on a ShopSabre CNC Router

ShopSabre CNC routers deliver clean, accurate, and repeatable cuts for toolbox foam, creating precise tool layouts with tight tolerances and smooth edges. Ideal for shadow boards, drawer inserts, and custom storage solutions, ShopSabre machines handle layered and dense foams with ease—helping shops improve organization, efficiency, and professional presentation in both one-off and production applications.

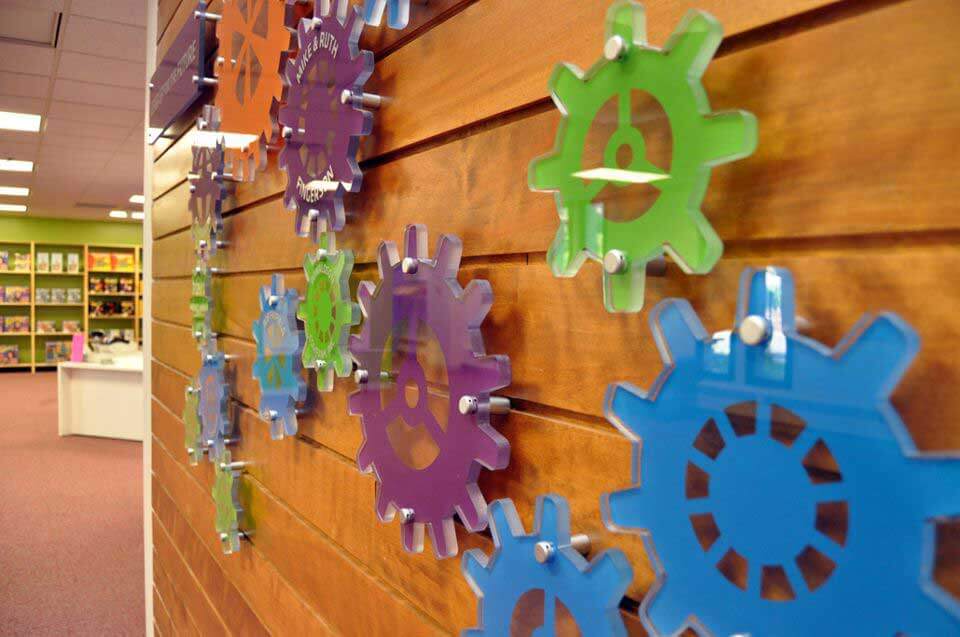

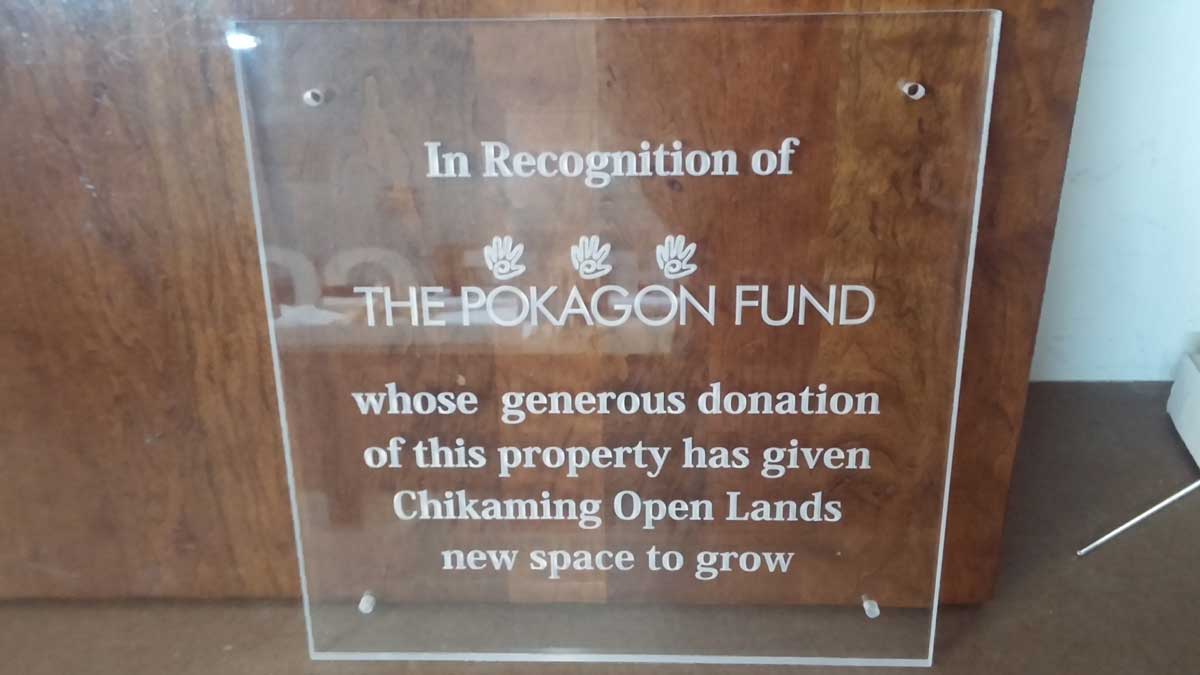

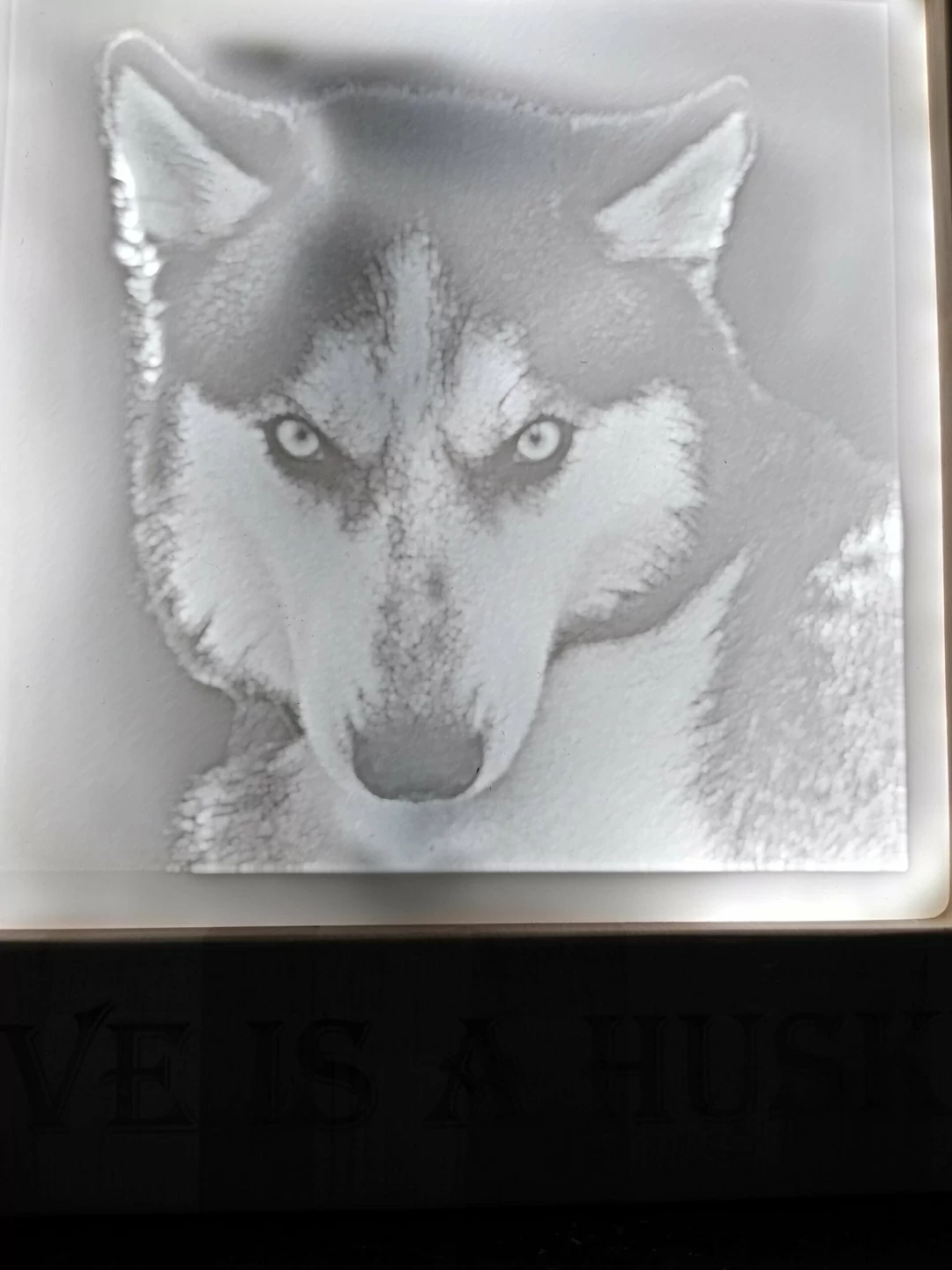

LED Edge Lit Acrylic Sign on CNC Router

ShopSabre CNC routers deliver the precision and surface finish required for LED edge-lit acrylic signage. From crisp engraved details to clean machined edges, ShopSabre systems produce clean light-transmitting features that enhance illumination and visual clarity. Ideal for custom signage, branding, and architectural displays, ShopSabre enables consistent, professional results in both prototype and production environments.

Built to Perform Accurately Every Time

- Tough Where It Counts: ShopSabre’s CNC machines for plastic are engineered with the same industrial-strength construction found across our full line, because even lightweight materials demand a rigid, reliable frame. You need a CNC machine for plastic that can hold tight tolerances without flex or chatter.

- Precision for Every Pass: From complex acrylic CNC machining to tight-tolerance plastic milling, every ShopSabre system is built to deliver clean edges and smooth finishes. Our machines use precision motion control systems and smart routing technology to give you repeatable results, minimize heat buildup, and reduce scrap, saving you time and materials.

- Speed Meets Control: When you need fast turnaround without sacrificing quality, ShopSabre delivers. Our high-speed drives and advanced control systems keep your shop moving, whether you’re prototyping a single part or producing full production runs with your CNC machine for plastic.

Designed To Be Efficient

- Room to Cut: Our larger working areas and optimized Z-clearances make it easy to handle oversized plastic sheets, stacked materials, or multi-pass tooling setups. From full acrylic signage panels to thick polyethylene blocks, you’ll get the cutting envelope you need, without the limitations.

- Versatile Enough for Any Plastic Job: ShopSabre machines are designed to handle a wide range of materials and applications. Whether you’re doing acrylic CNC machining for signage, CNC plastic cutting for displays, or plastic milling for machined parts, these machines give you the flexibility to adapt without switching platforms.

- Fully Assembled and Ready to Cut: Every ShopSabre plastic CNC machine arrives fully assembled, calibrated, and ready for production. You’ll be up and running faster, with support from a U.S.-based team that knows the demands of CNC plastic cutting.

Built to Grow With Your Business

Every ShopSabre CNC machine for plastic is made to grow with your shop. Our systems support expanding workloads with field-upgradable options and advanced motion control. Easily integrate your design software using Windows-compatible controls, and take on more complex CNC plastic cutting without skipping a beat.

The Best CNC Machines For Plastics

IS EVA Series

Whether you’re working on acrylic displays, plastic components, or industrial parts, the IS EVA Series delivers production-grade power and precision for plastic CNC cutting.

- Optimized for Large Plastic Sheets: Available in 4′ x 8′, 5′ x 10′, and 6′ x 12′ sizes, the IS Series is perfect for routing full-size plastic sheets, including polycarbonate, acrylic, HDPE, and more.

- Production Efficiency Built In: With an at-machine Windows OS and point-and-click nesting software, you can streamline your acrylic CNC machining or plastic milling workflow directly at the machine.

- Versatility that Works for You: From tight-tolerance prototypes to high-volume plastic part runs, the IS Series handles tough materials without compromising edge quality or cut accuracy.

What It’s Best For: Medium to high-volume shops that need a powerful, American-made CNC machine for plastic cutting, signage, displays, and more.

PRO EVA Series

Engineered for shops that demand tight tolerances and reliable output from a wide range of materials, including plastics.

- Steel Frame Construction: Precision-milled structural steel gives this plastic CNC machine the backbone it needs for clean cuts and high repeatability.

- Ball Screw Motion System: Anti-backlash design keeps your cuts smooth, especially important for detail-heavy plastic milling and engraving.

- Servo Motor Control: Top-tier servo motors allow fast, accurate movement for consistent performance across acrylic, HDPE, polycarbonate, and more.

- Built for Multi-Material Use: Perfect for shops routing plastic one day and aluminum or wood the next. Get flexibility without compromise.

What It’s Best For: Established shops scaling production with high-speed, high-accuracy machines for plastic, composites, and mixed material jobs.

RC EVA Series

The RC EVA Series brings entry-level affordability without cutting corners, perfect for first-time plastic CNC machine buyers or small shops stepping into CNC automation.

- Floating Drive Technology: Our exclusive inverted rack-and-pinion system increases torque and reduces wear, great for versatility in plastics like PVC, ABS, and acrylic.

- Integrated Tool Measurement: Ensures reliable cuts across different setups, critical for shops doing repeat CNC plastic cutting or small-scale production.

- Dust Skirt & Clean Workspace: Quick-release dust skirt simplifies cleanup, helpful when milling plastics that create static-prone chips.

- User-Friendly Software: Includes a full license of Vectric VCarve PRO for easy 2D, 2.5D, and 3D design, perfect for signage, panels, and acrylic CNC machining.

What It’s Best For: Budget-conscious shops and first-time CNC users looking for a reliable, low-maintenance CNC plastic cutting machine made in the USA.

ShopSabre 23 CNC Router

Compact, precise, and made for serious plastic routing in small spaces, the ShopSabre 23 brings industrial features to your bench.

- Powerful, Flexible Routing: Features a variable RPM 3.5HP router (with upgrade options), perfect for cutting plastics without melting or edge chipping.

- Heavy-Duty Ball Screw Design: Delivers motion precision across all axes, essential for high-detail plastic CNC work like custom panels, signs, and parts.

- Rigid Steel Gantry & Frame: Built from welded structural steel, offering a rigid platform for plastic milling that outclasses other entry-level machines.

- Smart Software & Control: Windows OS-powered onboard PC with point-and-click CAD/CAM software, plus lifetime tech support and training via SabreNation.

What It’s Best For: Small shops, schools, or prototyping teams needing a precision CNC machine for plastic that’s affordable, compact, and powerful enough to grow with your workflow.

Why Plastic Fabricators Trust ShopSabre

When you choose a ShopSabre CNC machine for plastic cutting, you’re investing in the future of your shop. Every ShopSabre CNC machine is built with the needs of acrylic fabricators, signage professionals, and industrial plastics manufacturers in mind.

That means tighter tolerances, smoother finishes, and fewer headaches, no matter what you’re cutting. From acrylic CNC machining to custom plastic milling and fabrication, ShopSabre routers deliver the control, consistency, and performance today’s shops demand.

Built in the USA

Every ShopSabre machine is proudly engineered, built, and supported in the United States. You get American craftsmanship backed by a company that understands what real production looks like.

With a nearly 98% satisfaction rating and industry-wide recognition for reliability, ShopSabre is a name trusted by thousands of businesses who expect more from their machines.

Lifetime Support from Industry Experts

Our support doesn’t stop at the sale. From initial setup to advanced troubleshooting and training, our U.S.-based tech team is here to help you get the most out of your machine for as long as you own it. Whether you’re refining your plastic milling techniques or tackling new materials, you’ll always have a partner in your corner.

Let’s Find the Right Machine for Your Plastics Work

Not sure which model is best for your plastic CNC cutting needs? We’ve got you covered. Schedule a free consultation with one of our in-house experts, and we’ll help you find the machine that fits your materials, your workflow, and your goals.