What Can You Do with a CNC Fiber Laser?

If you work with metal, chances are you’ve thought about bringing a CNC fiber laser into your shop. But what exactly can you do with one, and is it worth the investment?

In short, a CNC fiber laser is one of the most powerful, versatile tools a metal shop can have. A CNC laser gives you fast, clean, repeatable cuts, without the mess or hassle of old-school methods.

Let’s break down what CNC fiber lasers like the ShopSabre FiberSabre can really do and why more shops are making the switch.

What Is a CNC Fiber Laser?

A CNC fiber laser uses a focused beam of light (amplified through fiber optic cables) to cut through metal with extreme precision. These machines are controlled by software, which means you can import digital files and produce repeatable, consistent parts without laying out templates or handling materials manually.

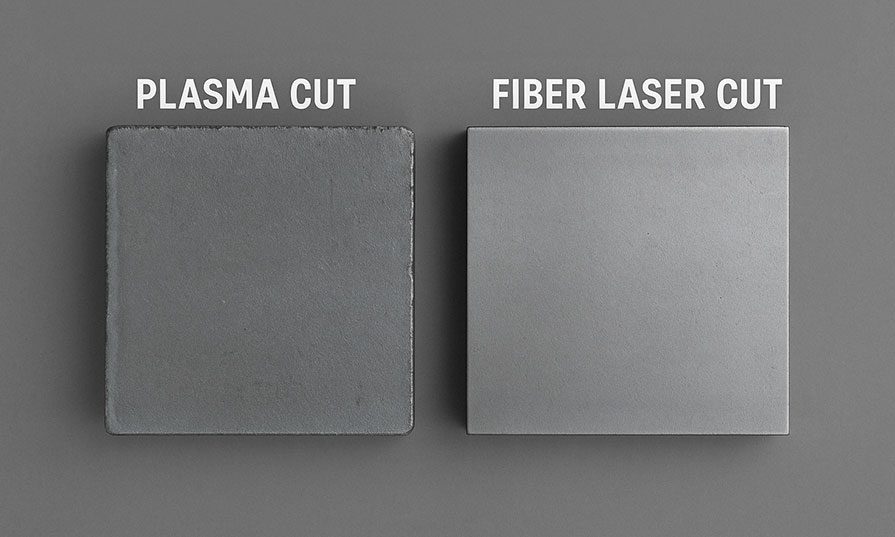

Unlike traditional plasma or CO2 laser systems, fiber lasers are faster, cleaner, and more efficient when it comes to cutting metal. They require less maintenance, waste less material, and don’t produce the same amount of heat distortion.

The FiberSabre from ShopSabre, for example, is built specifically for metal fabrication and is available in both 2kW and 6kW options, depending on the thickness and speed your work demands.

What Can You Cut with a CNC Fiber Laser?

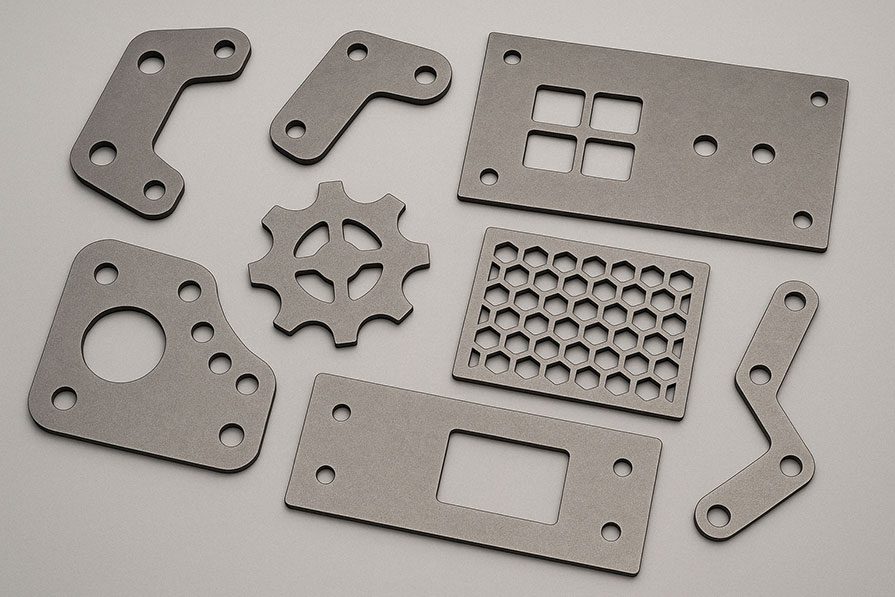

From thin-gauge sheet to heavy plate, a CNC fiber laser like the FiberSabre handles the metals that fabrication shops rely on every day — cleanly, quickly, and with no extra steps.

Whether you’re cutting steel for structural parts, stainless steel for clean finishes, or aluminum for lightweight builds, this machine delivers sharp, precise edges that are ready for whatever comes next: welding, assembly, or straight to powder coat.

It’s equally effective with more challenging materials like copper and brass, giving you the freedom to take on intricate designs or detailed custom work without slowing down.

Here’s what real users are cutting with their FiberSabre:

- Sheet metal panels

- Ductwork components

- Custom signs and artwork

- Metal brackets and tabs

- Chassis mounts and brackets

- Electrical panels

- Decorative grilles

- Prototype parts and assemblies

Who Uses CNC Fiber Lasers?

Not sure if a CNC fiber laser fits into your shop? You’re not alone. A lot of folks are surprised to find just how many industries rely on this kind of tech every day. If you’re working with metal — cutting it, shaping it, building something from it — a fiber laser can make your job faster, cleaner, and a whole lot easier.

So, who’s actually using them?

Automotive Shops

Custom car builders, hot rod garages, and motorsports teams use fiber lasers for bracketry, panels, mounts, and frame tabs. Fiber lasers are a game-changer when producing short runs or prototyping new designs.

HVAC and Sheet Metal Contractors

Fiber lasers are ideal for cutting galvanized and stainless steel sheets for ductwork, vents, brackets, and mounting hardware. With CAD-compatible software, you can go from drawing to finishing a part without leaving the shop.

Fabrication Shops

A fiber laser boosts your capacity without adding labor for custom metalwork, small batch jobs, and one-off components. You can easily swap materials, run different cut files, and handle jobs that used to require outsourcing.

Prototyping & R&D

Designers and engineers can quickly test shapes, materials, and tolerances using a fiber laser. The precision helps reduce revision cycles, which saves time and money.

Signmakers & Decor Artists

If you’re cutting intricate patterns or artwork into sheet metal, nothing beats a laser for detail and consistency. From industrial signage to custom wall art, fiber lasers deliver crisp, professional results.

Is a CNC Fiber Laser Right for Your Shop?

If you’re still outsourcing metal parts — or spending too much time with grinders, snips, and templates — a CNC fiber laser could pay for itself faster than you think. It brings more work in-house, reduces turnaround times, and gives you more control over the final product.

And if you’re already using a plasma table but want cleaner, more detailed cuts? A fiber laser is your next step forward.

Why Choose the ShopSabre FiberSabre?

There are plenty of CNC lasers out there, but the FiberSabre stands out for a few key reasons:

Made in the USA

Unlike many competitors, the FiberSabre is built here in America. That means high-quality construction, better support, and machines designed for real-world shops, not mass-produced imports.

Runs on Single-Phase Power

You don’t need to rewire your entire building to run this laser. The 2kW model runs on standard 220V single-phase power, making it accessible for smaller shops or garages.

Built for Daily Use

With an Aerospace-milled steel frame, advanced digital servo motors, industrial-grade rails and bearings, and dual-drive axes, the FiberSabre is designed to run hard without wearing out.

Smart, User-Friendly Features

- Pull-out material drawers for faster loading

- Clean-out trays to make maintenance simple

- Pre-loaded material libraries and laser-cut charts

- Collision-detection laser head

- Easy-to-use CAD/CAM software with point-and-click interface

Lifetime Tech Support

Every FiberSabre comes with free lifetime tech support and access to ShopSabre’s training resources. So, even if CNC lasers are new to you, you won’t be left guessing.

Ready to Bring Laser Precision to Your Shop?

So, what can you do with a CNC fiber laser? The real question is: What do you want to do next?

From speeding up production to taking on more complex projects, the FiberSabre puts the tools in your hands to build better, work faster, and stay ahead of the curve.

Still have questions about which model to choose or whether your shop is ready for a fiber laser? Let’s talk.