What Contributes to Pricing Variances in CNC Machines?

When it comes to CNC machines, the pricing gap is massive. You’ll find entry-level machines for as low as $4,000, while high-end industrial models can hit $400,000 or more. But why such a drastic difference? Is it just brand recognition, or are you actually getting what you pay for?

Let’s break down the factors that drive CNC machine pricing and help you understand where your money is going when you invest in quality CNC technology.

Build Quality and Materials

At the core of any CNC machine is its structural integrity. The materials used in the frame and components directly impact the machine’s precision, longevity, and overall performance.

Let’s look at some of the most crucial aspects of a CNC machine:

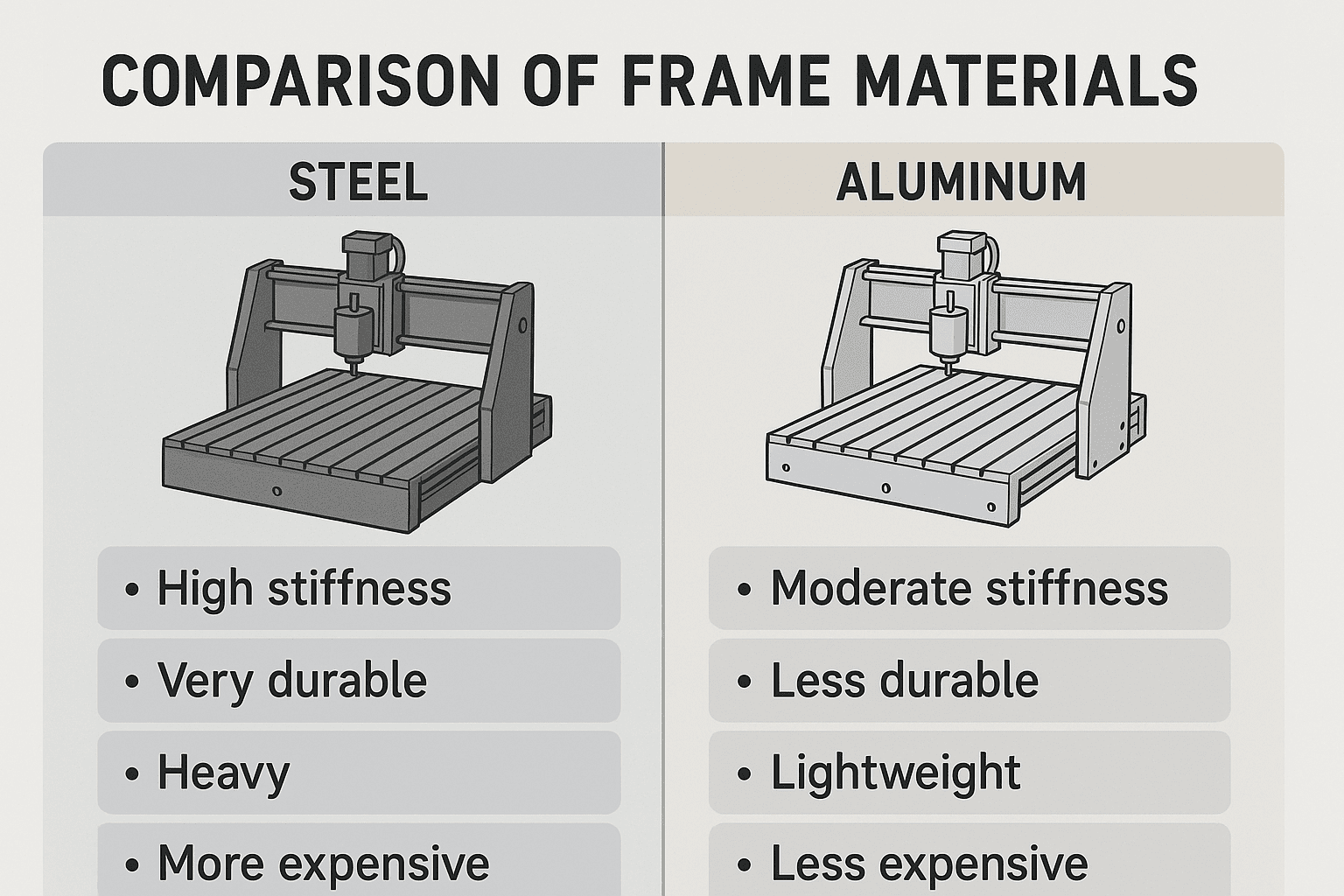

- Structural Steel vs. Bolted Aluminum Frames: High-end machines, like those from ShopSabre, are built from welded structural steel, offering unmatched rigidity and vibration resistance. Cheaper machines often use bolted-together aluminum frames, which lack the same stability and can lead to inconsistent cuts.

- Drive Systems and Ball Screws: Precision components like ball screws and linear guides play a massive role in accuracy. High-quality machines use industrial-grade components that reduce backlash and ensure smoother operation. Lower-end machines often cut corners with cheaper drive systems that wear out faster.

Component Quality and Performance

Not all parts are created equal. Two machines might look similar from 10 feet away, but under the hood, the differences are night and day.

One common example is the vacuum pump. A lower-end machine might use a pump that produces 9.6 inches of vacuum pressure, while a ShopSabre machine uses a pump that delivers 24 inches. The result? Better material hold-down and cleaner cuts.

Another example is the controllers and electronics. Industrial-grade controllers provide better motion control and smoother cuts. Cheaper machines often use imported electronics, generic control programs, or one-off proprietary systems that lack support and struggle with complex toolpaths and high-speed cutting demands.

Precision and Accuracy

CNC machines are all about precision, but achieving that precision requires more than just slapping on name-brand components. Putting nice cabinets in a collapsing home does not make the homes the same.

A machine built for high-speed production needs a rigid gantry to handle heavy loads without flexing. Lower-priced machines often sacrifice material quality which results in loss of rigidity, leading to inconsistent performance & dependability issues long term.

High-end machines are designed to hold tight tolerances over thousands of cuts. Budget machines often struggle to maintain accuracy over time, leading to wasted material and more operator intervention.

Machine Support and Service

When you’re comparing CNC machines, support and service are often overlooked — but they shouldn’t be. The reality is, it’s not all the same, even if the sales guy tells you it is. Downtime costs you money. And when you’re relying on a machine to keep your shop running, having access to parts and support can make or break your investment.

That’s where lifetime support comes in. But what exactly does that cover? Are you limited on how many times you can call for help? Is there a cap on service hours? Who’s lifetime? Is it until they discontinue your machine or until you sell it?

Finding replacement parts or a qualified technician can be a nightmare with cheaper machines, especially if the model is discontinued or the importer goes out of business. Meanwhile, brands like ShopSabre invest heavily in customer support, offering unlimited assistance for the life you own your machine.

No hidden fees. No limits. Just real, knowledgeable support when you need it.

You also have to consider the long-term cost of maintenance. Things like wear and tear on gears versus ball bearings, software updates, and proprietary technology all factor in. If a company suddenly stops supporting your machine, are you left stranded?

These are the questions that matter when you’re making an investment — not just the upfront cost, but the true cost of keeping your machine running for years to come.

Production Speed and Efficiency

A $250,000 machine isn’t just more expensive, but it’s built to handle higher production demands.

Here are just a couple of benefits to investing in quality machines:

- High-Speed Servo Motors: Industrial CNC machines are equipped with high-torque servo motors that allow faster cutting speeds without sacrificing accuracy.

- Reduced Labor and Finishing Work: Cheaper machines might require multiple passes or additional sanding and finishing, which adds to your labor costs. A higher-end machine can cut cleaner and faster, saving time and money in the long run.

Hidden Costs of Cheap CNC Machines

People often ask why one CNC machine costs $10,000 and another costs $100,000. It’s not just about the machine itself but what’s behind it. You’re investing in the engineering, material quality, strength, support team, service, and the unmatched reliability that comes with a trusted brand. Cheaper machines often come with limitations, downtime, and poor support. For most, well, they can’t afford that.

What looks like a deal upfront often turns into a money pit over time.

- Frequent part replacements

- Inconsistent accuracy and wasted materials

- Higher labor costs due to finishing and rework

- Limited support when something breaks

Proven Brands vs. Cheap Alternatives

You know the difference when you’re working with a proven brand. Think about it — you probably trust your Apple Watch or earbuds because they’ve built a reputation for quality and reliability. The same logic applies when you’re investing in equipment for your shop. Do your research. Watch case studies, read reviews, and visit manufacturing plants.

When you can see how a machine is built and feel the quality firsthand, you gain confidence in your investment — something you’ll never get from a cheap knockoff.

Buying From the Source Often Means Lower Costs and Higher Quality

You’ve probably learned the hard way that cutting corners on equipment only leads to headaches. That’s why buying directly from the factory is the smarter move. When you skip the middleman, you know exactly what you’re getting — quality craftsmanship and direct support from the people who actually built the machine.

Factory-direct products hold up longer and perform better. Plus, the support you get is worth every penny.

So, Why Are ShopSabre Machines (Sometimes) More Expensive?

Because they’re built to perform — and built to last.

When you invest in a ShopSabre CNC, you’re not just paying for the machine itself. You’re paying for American-made quality, precision engineering, industrial-grade components, advanced technology, better performance, and lifetime support from a team that knows CNC inside and out.

Even then, you’ll find that even our most expensive CNC machines still beat out other, even more expensive competitors. So yes, you can buy a $4,000 CNC machine, but you’ll likely outgrow it, struggle with performance, and spend thousands more in repairs and replacements.

In the world of CNC, you get what you pay for, so always ask yourself: “Is this built for the long haul?” If the answer is no, you’re better off looking elsewhere. Buy your second machine the first time.

And if your answer is yes, chances are you’ve found yourself checking out a ShopSabre machine.

Still curious about CNC machine pricing? Listen to our podcast episode, “Why Are Some CNC Machines More Expensive?” to get our complete thoughts.