Description

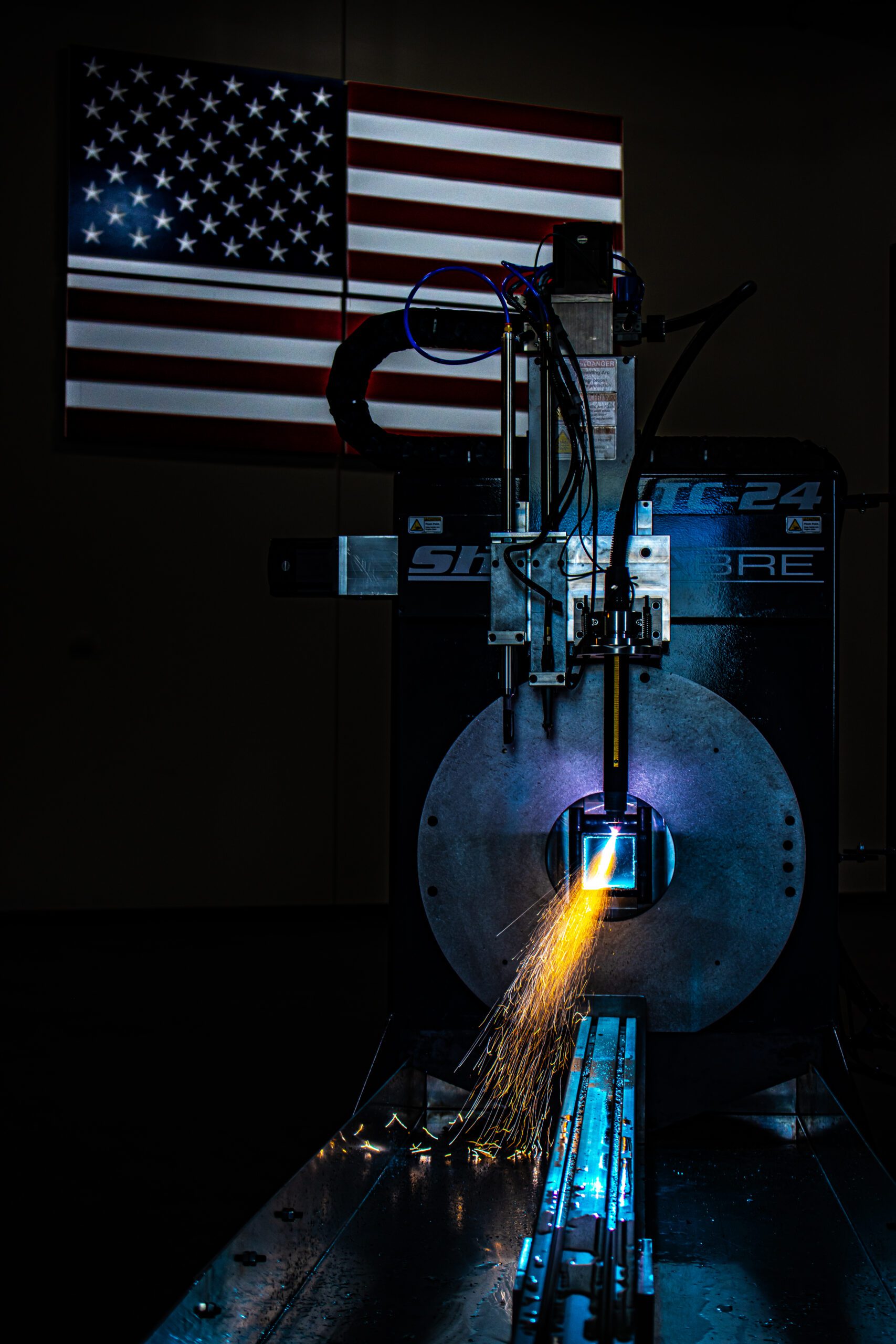

PRECISION TUBE & PIPE CUTTING

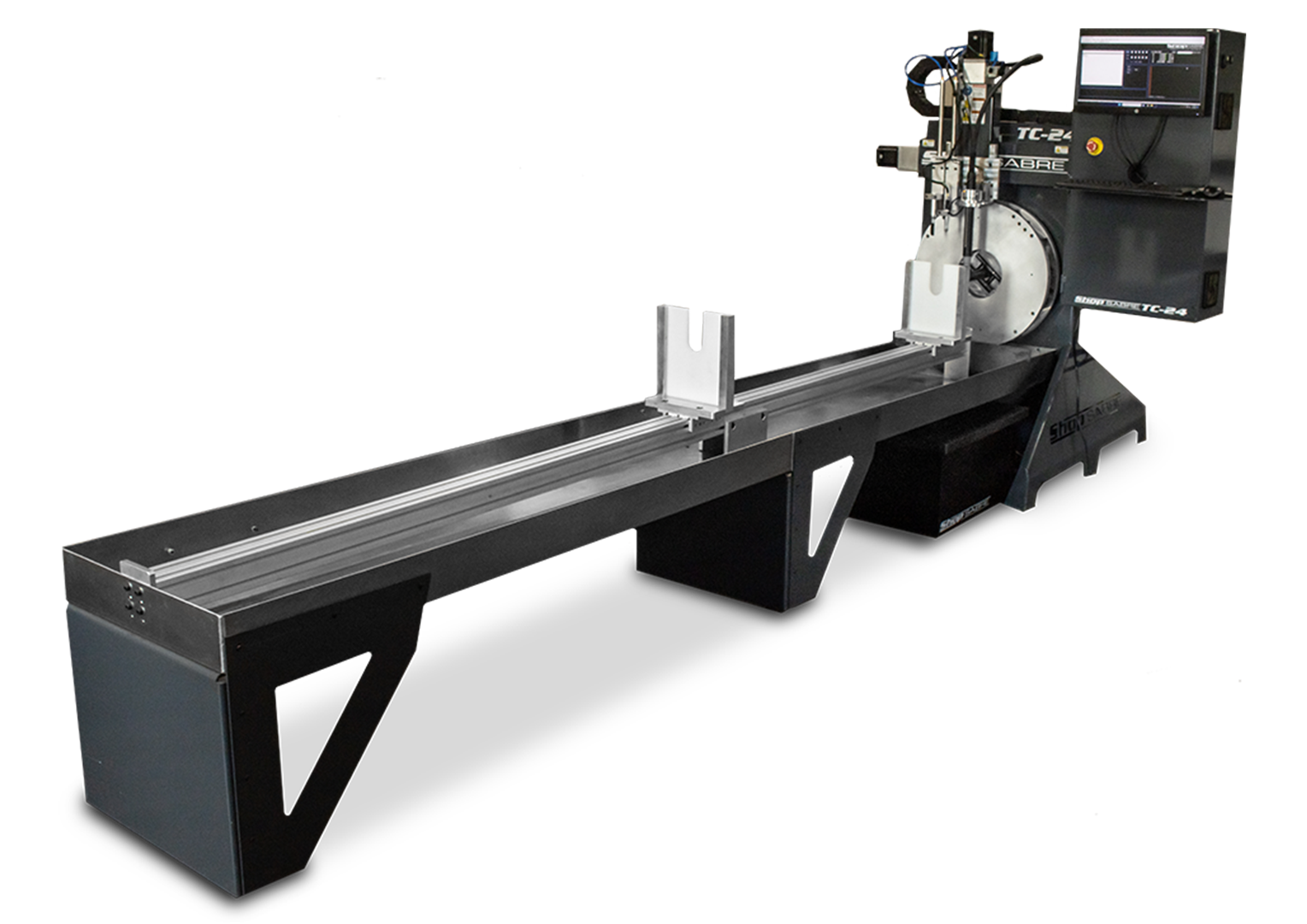

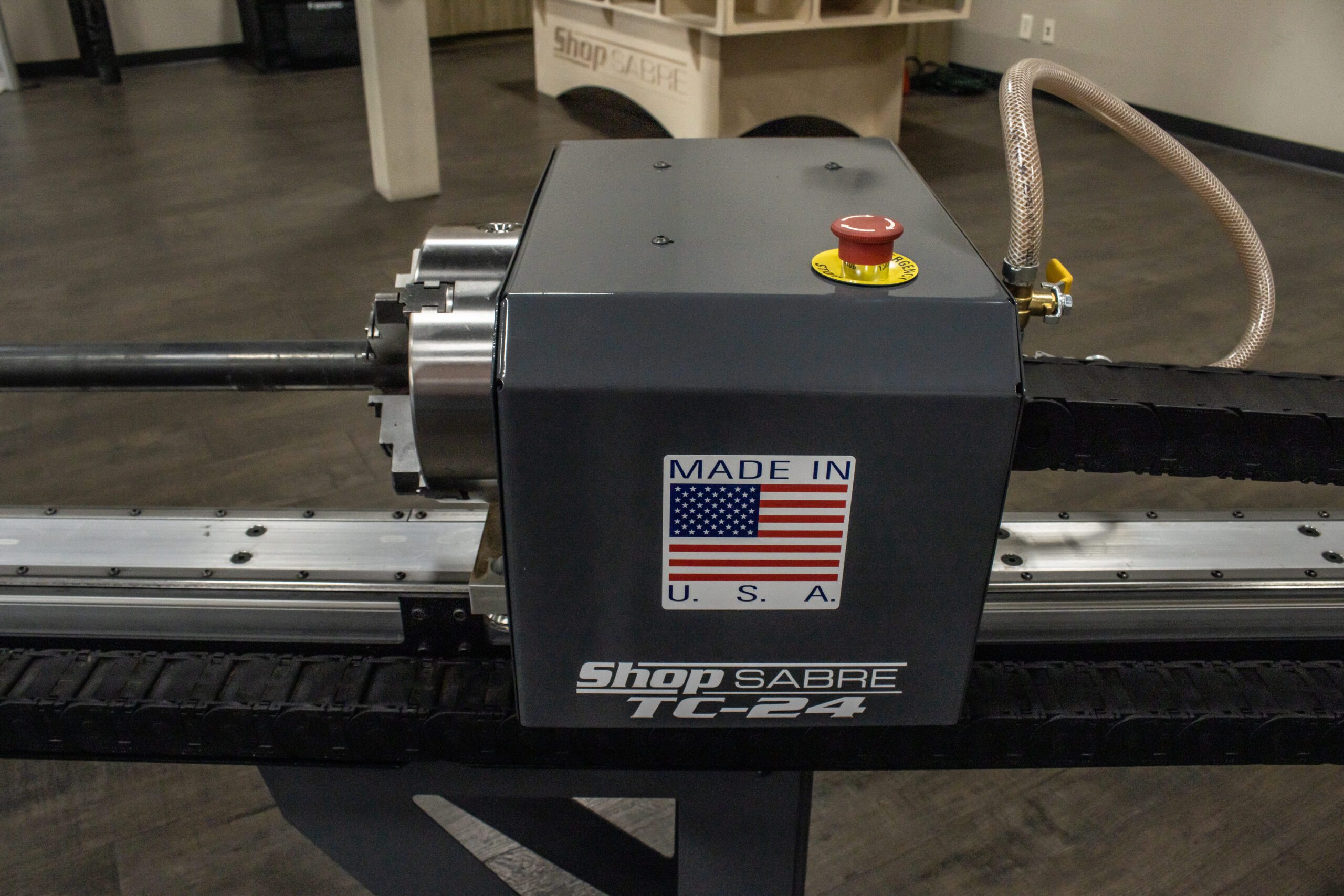

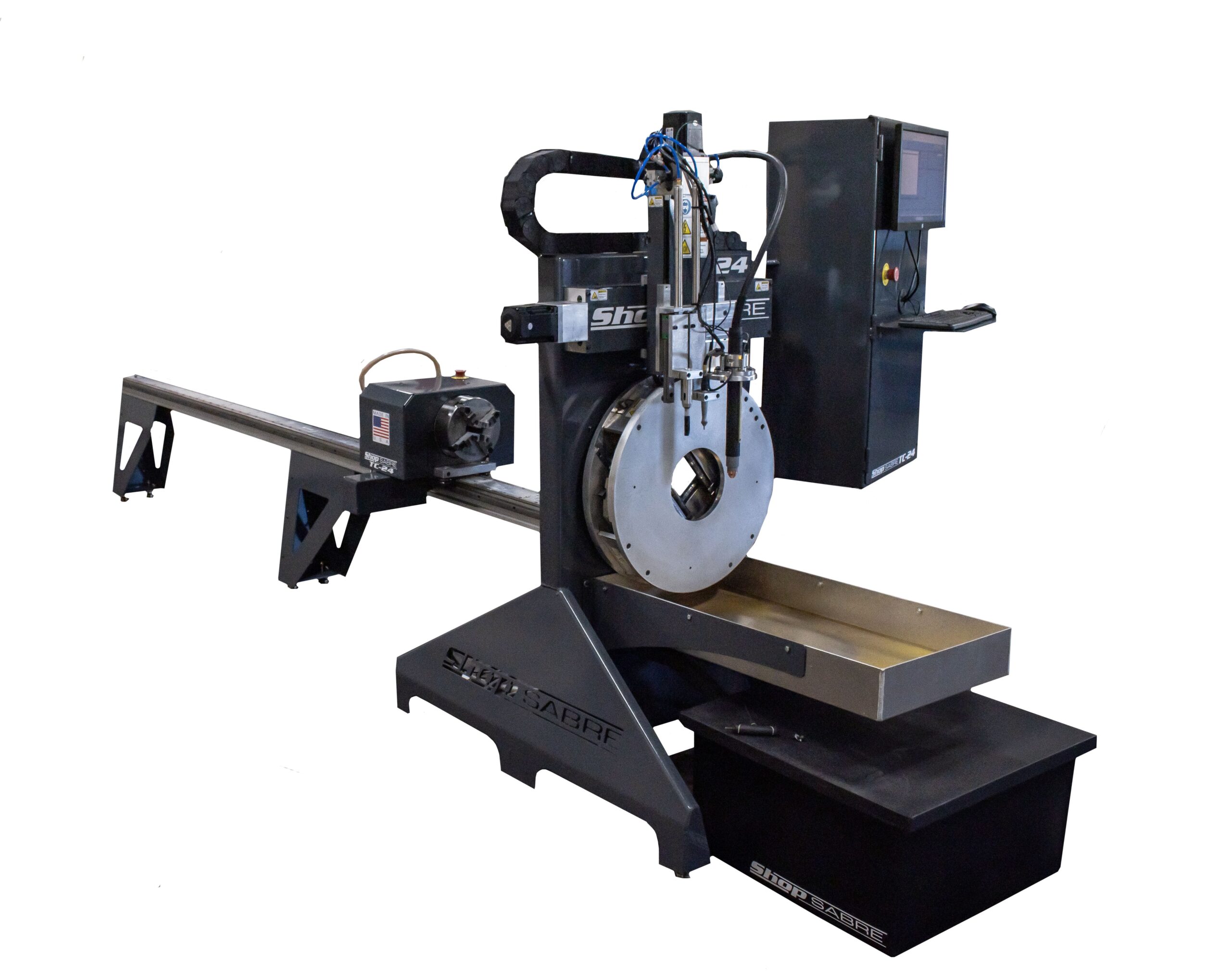

The ShopSabre Tube Cutter (TC) Series is proudly engineered and manufactured in Lakeville, Minnesota, featuring a robust, American-made design backed by our industry-leading support. This machine offers the versatility to process round, square, and rectangular tube from a single system with ease. Whether you’re working on decorative designs (gates, railings, fences), motorsports fabrication, automotive and off-road builds, exhaust systems, or general pipe fabrication, the TC Series is a must-have tool.

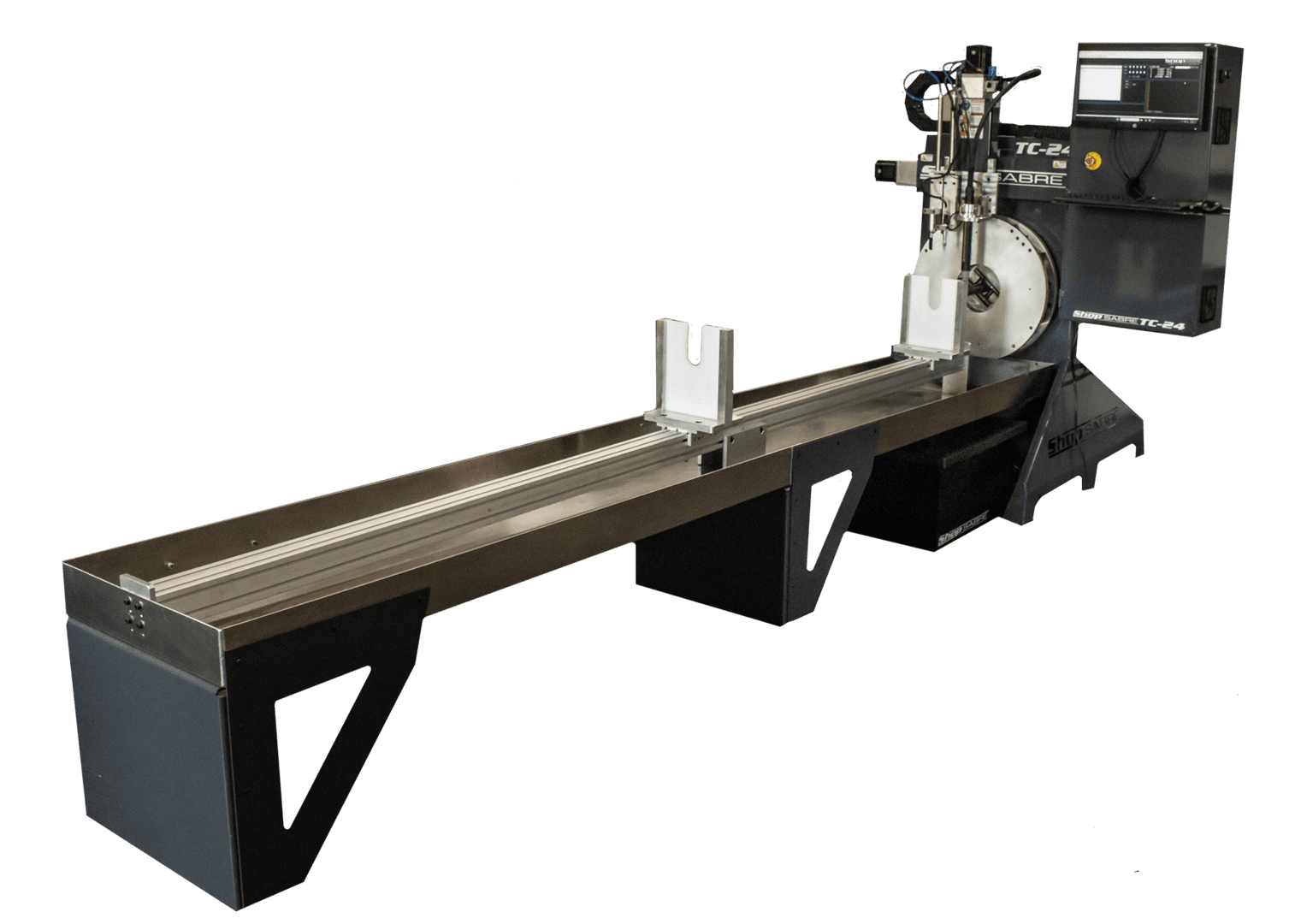

Available in two sizes—TC-12 for 12-foot processing and TC-24 for 24-foot processing—the TC Series gives you flexibility to match your production needs. Choose between a round-only chuck or an advanced chuck capable of handling round, square, and rectangular tubing.

Both models feature an onboard computer system, Hypertherm Rotary Tube Pro software, and an industrial-grade frame with a steel 8” tailstock supporting up to a 7” hypotenuse passthrough. If you’re looking for a CNC tube cutter that will revolutionize your fabrication process, look no further than the ShopSabre TC Series!

Highlighted Features

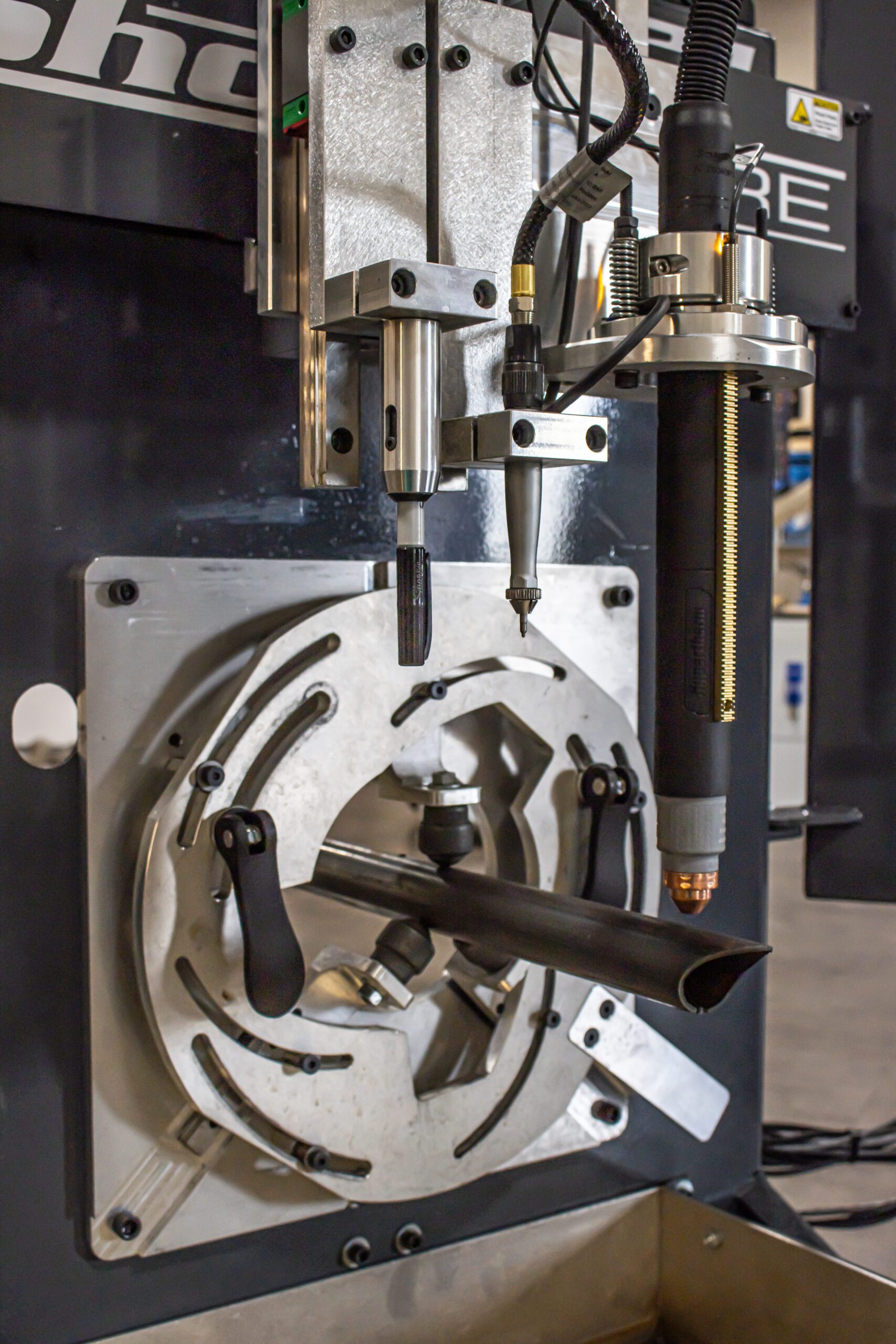

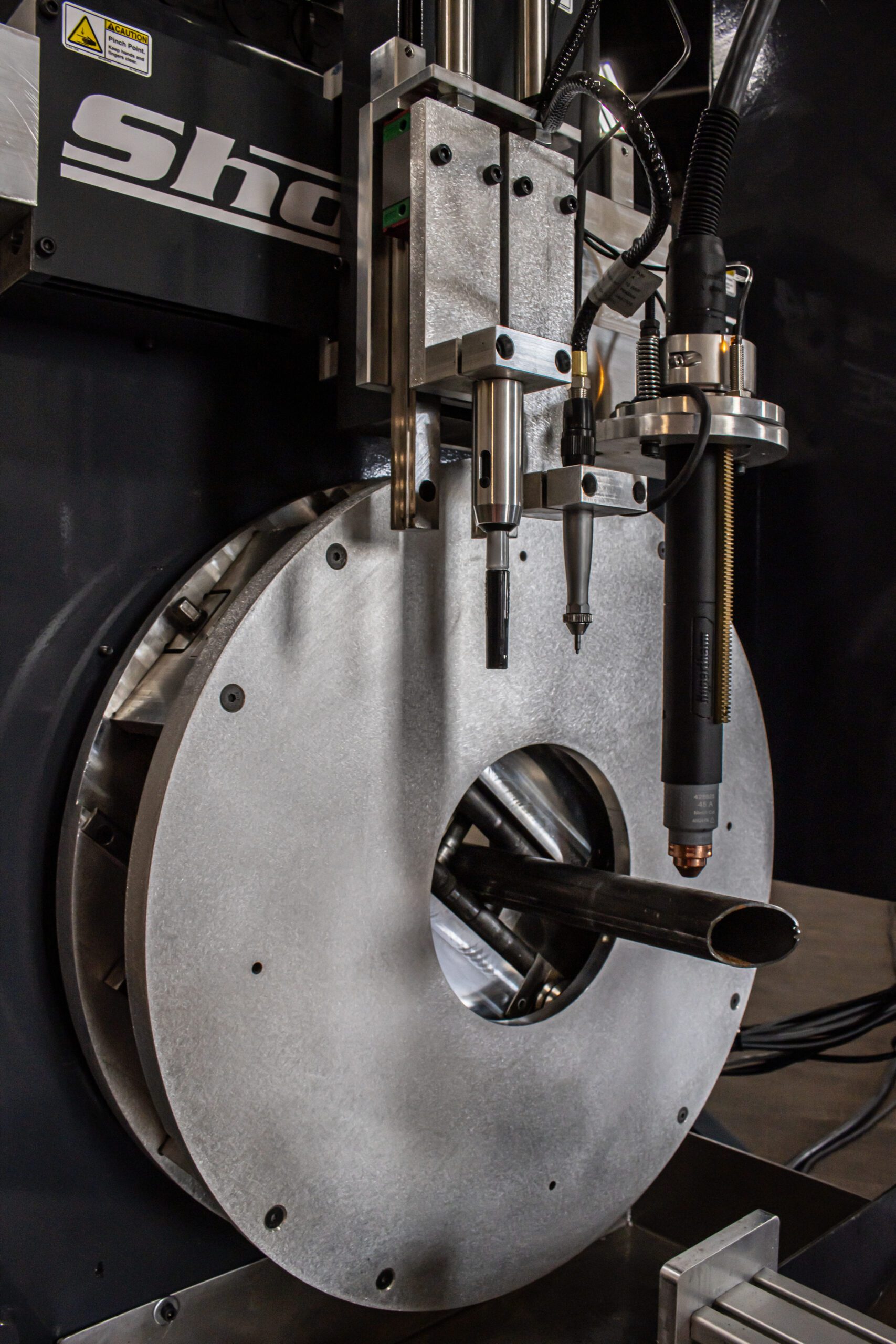

- Torch Collision Detection for enhanced safety and precision

- Laser Sight for quick and accurate XY zeroing

- Hypertherm Rotary Tube Pro software included for optimized tube cutting

- ShopSabre On-Board Controller with integrated PC system, at-machine Windows OS, and storage hard drive

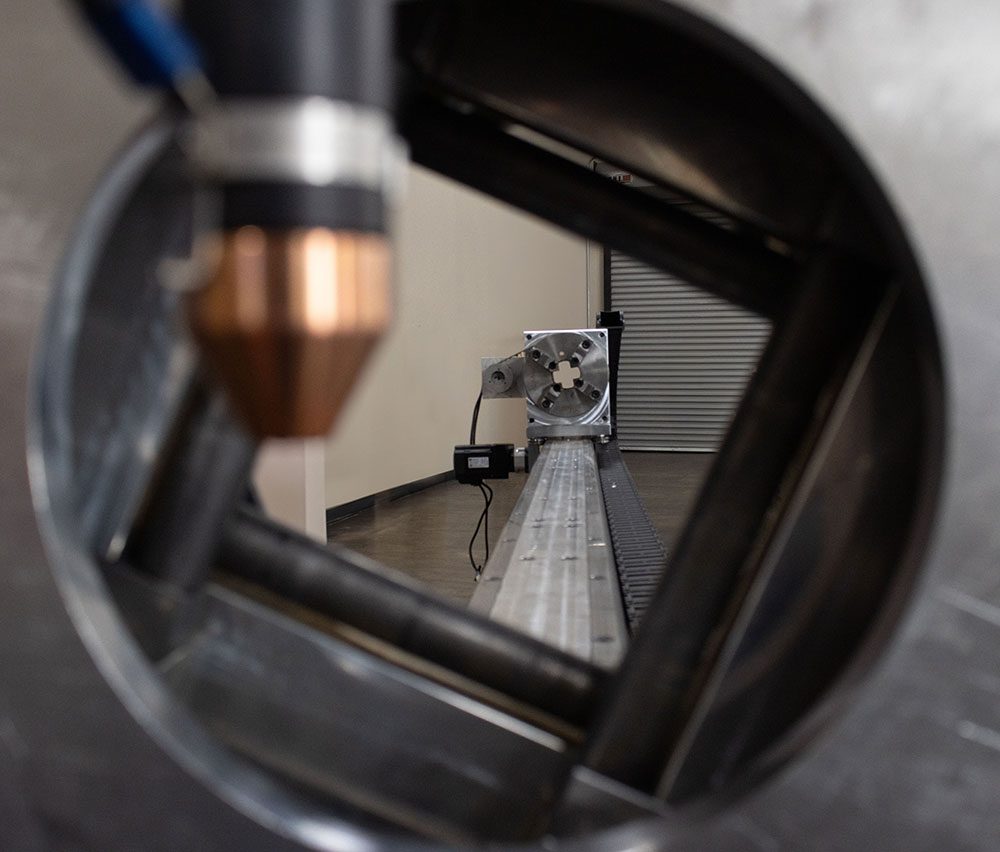

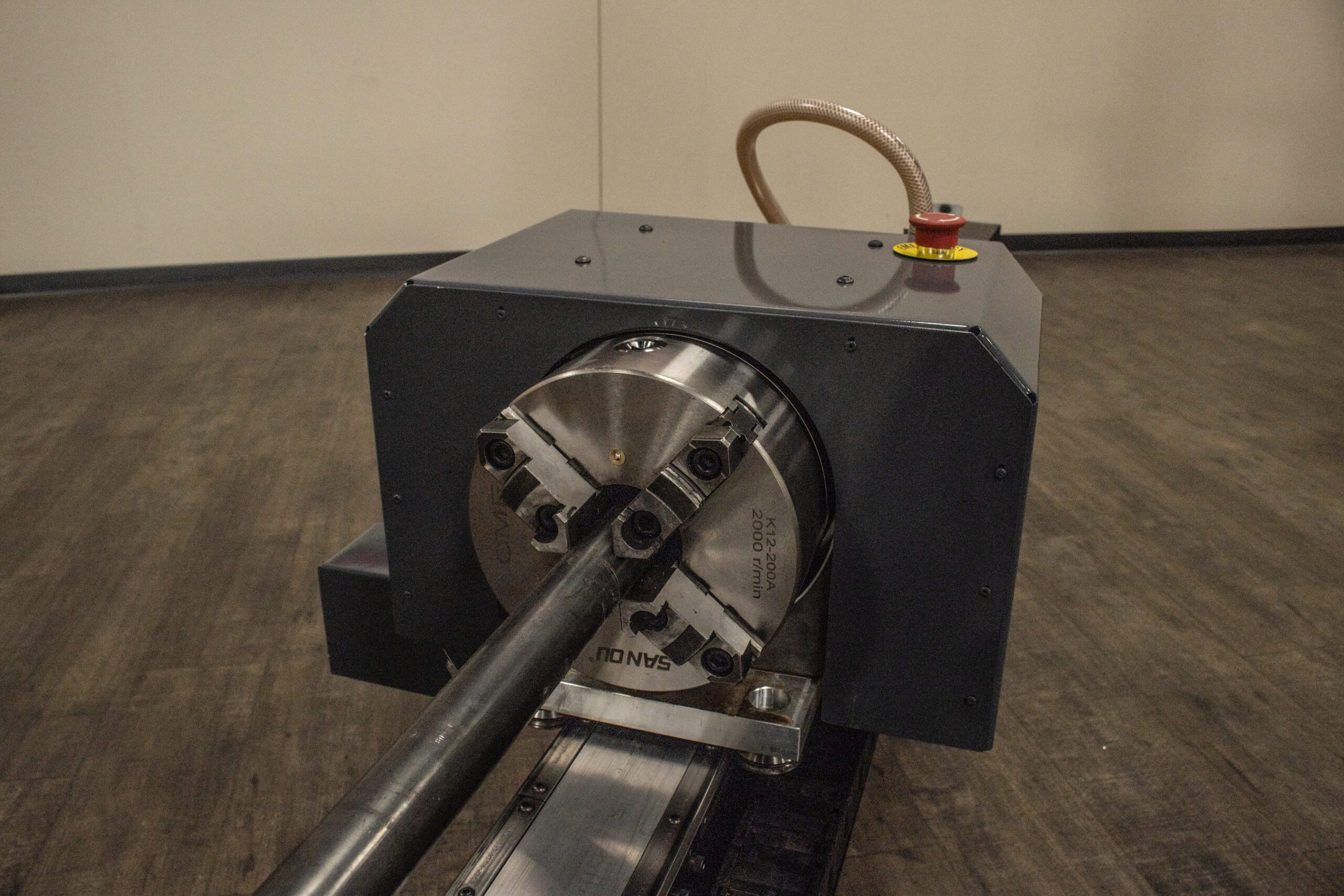

- Optional 4-Jaw Chuck for round, square, and rectangular tube applications

- Optional Marking Package – Includes marker pen & scribe for engraving and layout marking

- Optional Hypertherm Plasma Cutter – Compatible with Powermax 45, 65, 85, and 105 models

- Optional SabreCool Water Cooling and Water Table (available in 4′ & 12′ sizes) help minimize heat distortion, extend consumable life, and improve fume and debris control.

Well Equipped

Includes:

- ShopSabre Tube Cutter CNC Plasma System

- Welded Structural Tube Steel Frame & Steel Machine Base

- Emergency Stop Switch

- Limit Switches on X,Y,Z Axis with Auto Squaring and Boundary Alarms

- Enclosed Wire Carriers for Wire Protection

- Heavy Duty Closed-Loop Motors with Encoder Technology on XYZ Axis.

- Plasma Cutter On/Off & Arc Confirmation Ports for Electronic Control

- TC Series Torch Collision Detection system with Auto Torch Alignment

- Advanced Digital Torch Height Control with Auto Touch System (THC) and Touch

Distance Control Technology - ShopSabre Industrial Controller Hardware & Software with at machine Windows OS

- ShopSabre Computer System – Full Size Desktop System, Windows OS with Solid

State Hard Drive, 16GB Memory, 19″ Flat Screen Monitor, Keyboard, Mouse - Hypertherm Rotary Tube Pro Software

- ShopSabre SabreNation Support Included– Life-Time Technical Support via Phone,

Email, and Remote Connectivity (Internet connection required) - XY Quick Zero Laser Sights

- USB Wireless for Computer Internet/Network Connectivity

- Hypertherm Powermax45 SYNC Plasma Cutter with machine torch connectivity and full system integration

- Upgraded 4 Jaw Head for use with Round, Square and Rectangle Cutting

- 4′ Water Table

Some items may be able to be removed or modified depending on needs

Tube Cutter 12 Foot (TC-12) |

Tube Cutter 24 Foot (TC-24) |

|

| Power Requirement | 110V – 15AMP | 110V – 15AMP |

| Operating Size | 168" x 70" x 60" | 312" x 70" x 60" |

| Cut Area | Maximum 144″ Length / Minimum size 12″ length | Maximum 288″ Length / Minimum size 12″ length |

| Maximum Material Thickness | 5/8" | 5/8" |

| Rotary Plasma Cutter | 12 foot (144 inches) long tube | 24 foot (288 inches) long tube |

| Minimum Process Length | 12 inches | 12 inches |

| Rapid Speed | 1500IPM Y Axis at 50% Weight Limit; 1000IPM Y Axis at 100% Weight Limit; 500IPM XZ Axis | 1500IPM Y Axis at 50% Weight Limit; 1000IPM Y Axis at 100% Weight Limit; 500IPM XZ Axis |

| Shipping Weight | 1500lbs | 1500lbs |

| Maximum Cutting speed | 15,000 degrees per minute - 41RPM | 15,000 degrees per minute - 41RPM |

| Well Equipped | $36,495.00 | $39,995.00 |

| Get a Quote | Get a Quote | |

Finance for as low as $635.00/month |

Finance for as low as $695.00/month |

Questions?

Are you not sure which CNC machine is right for you and your production? Schedule a free consultation with one of our in-house experts for personalized, one-on-one guidance.

ShopSabre TC Series Features

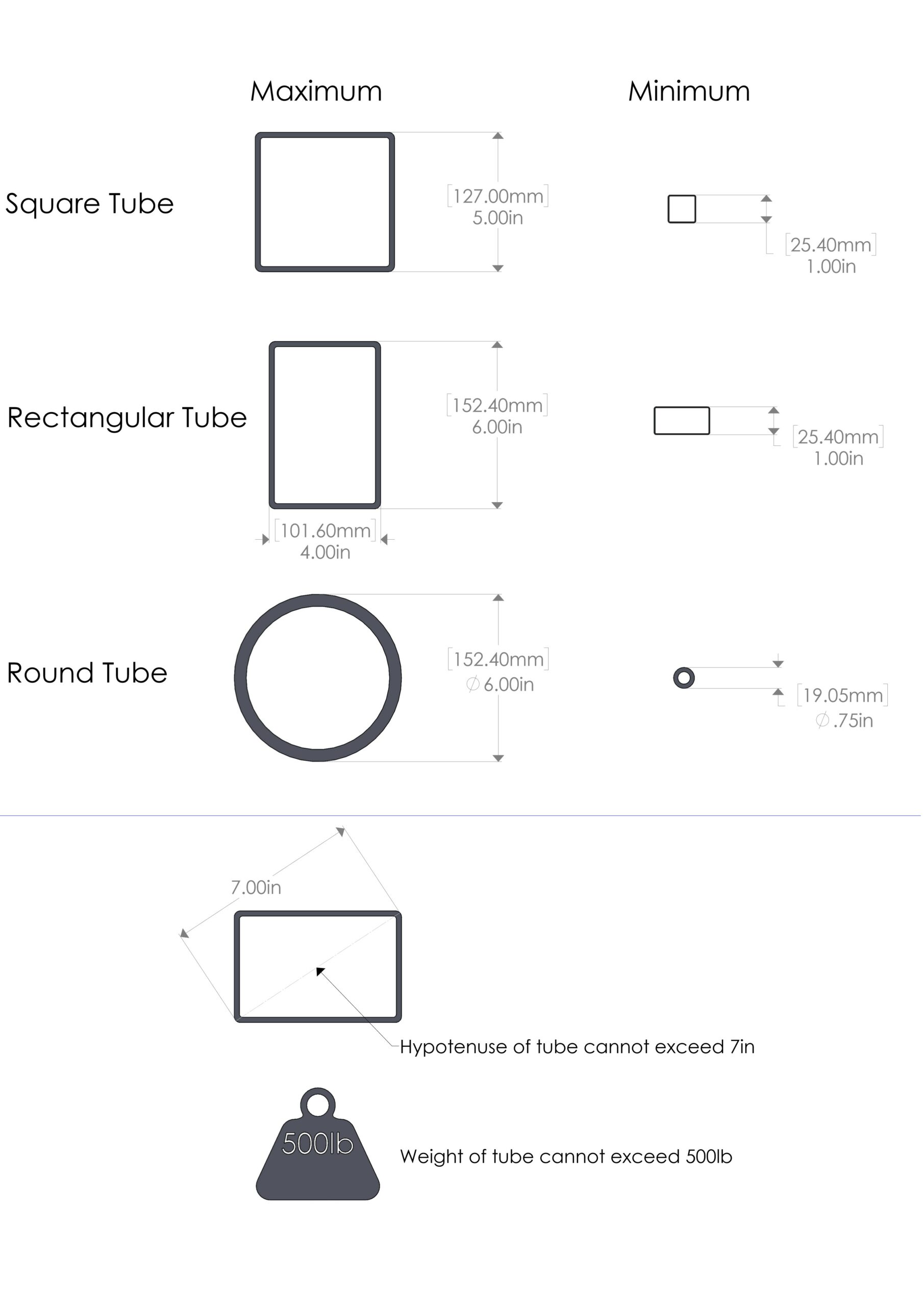

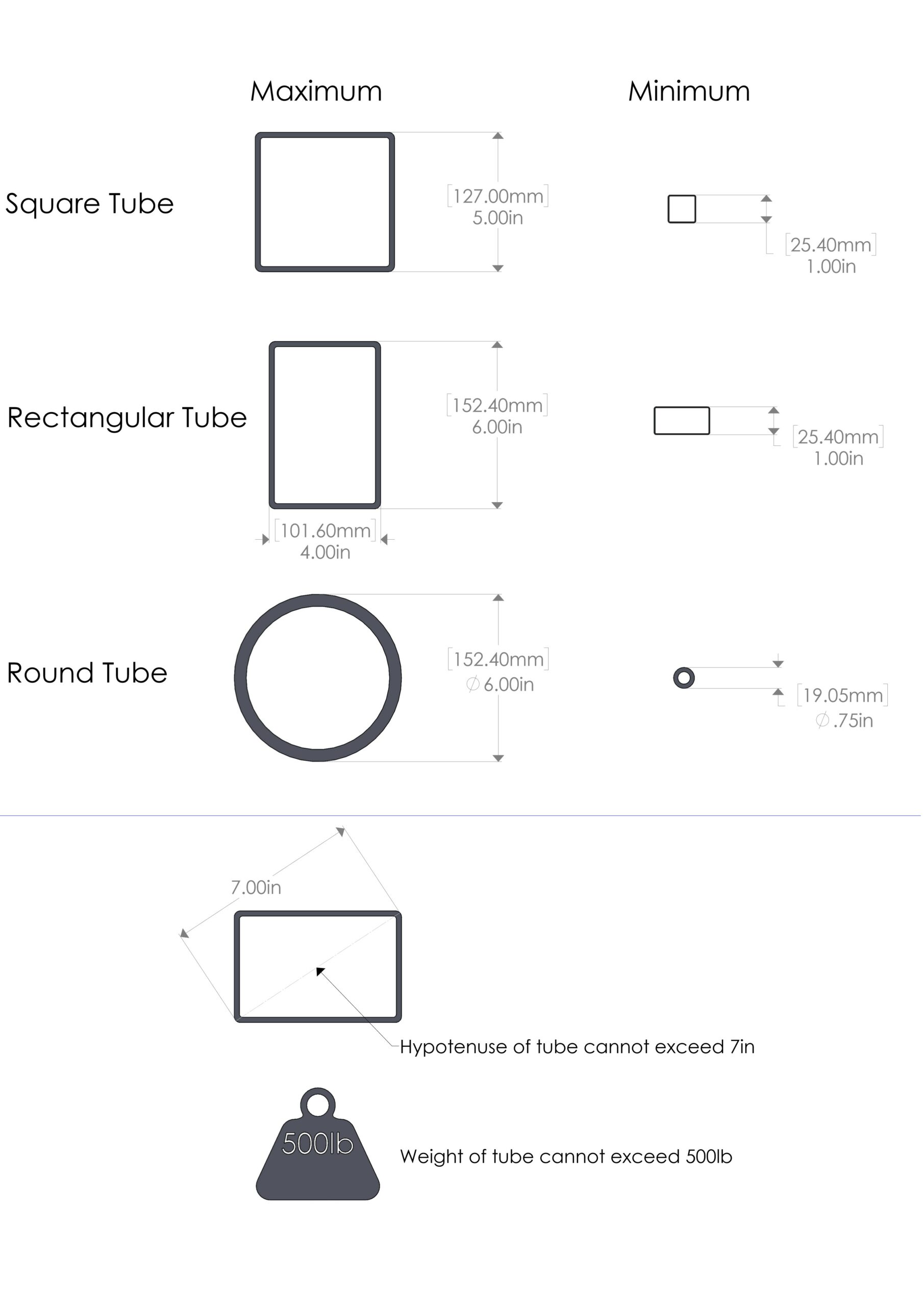

Dimension limits diagram

ShopSabre TC Series Features

Dimension limits diagram

ShopSabre TC Series Details

Finance Calculator

Finance Calculator