How Does a CNC Router Work?

TLDR / Key Takeaways

- CNC routers use computer control to move a cutting tool along X, Y, and Z axes

- They read a program called G-code that tells the machine exactly where and how to cut

- CNC routers are commonly used for wood, aluminum, composite materials, plastics, and more

- Ideal for shops that need precision, repeatability, and scalable production

A CNC router works by following digital instructions that control the movement of a spindle and cutting tool. The machine removes material from a workpiece along three axes to create precise parts, shapes, and designs. It is a fully automated routing process guided by G-code rather than manual operation.

What is a CNC Router?

A CNC router is a computer numerical control machine that automates cutting, shaping, drilling, and carving. It is often used for applications like cabinetry, sign making, prototyping, and general fabrication. Because the cuts follow computer instructions, the results are consistent and repeatable across multiple parts.

CNC routers are most common in woodworking shops and light industrial environments. They offer a larger cutting area than many CNC mills and are well-suited for sheet goods and large panels.

The Main Components of a CNC Router

|

Component |

What It Does |

|

Spindle |

Holds and rotates the cutting tool at high speeds |

|

Gantry and Axes System |

Moves the tool head precisely in X, Y, and Z directions |

|

Machine Bed |

Supports and secures the workpiece during cutting |

|

Motors and Drives |

Control the motion and accuracy of each axis |

|

Controller |

The computer hardware and software that read the G-code and direct machine movement |

Advanced machines may include automatic tool changers that allow multiple bit types to be swapped without manual intervention

How Does a CNC Router Work Step by Step?

CNC routing is an automated cutting process that turns a digital file into a finished part with precision and repeatability. Here is what the workflow looks like from start to finish:

1. A Digital Design is Created

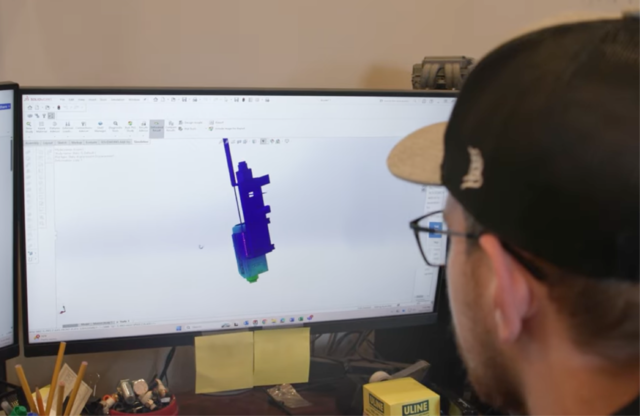

Every CNC routing project begins in CAD (Computer Aided Design) software. The operator draws a 2D layout or 3D model that represents the exact shape and dimensions of the final part. This digital file becomes the blueprint for the cutting process.

2. The Design is Converted Into Machine Instructions

Next, the design is imported into CAM (Computer Aided Manufacturing) software. Toolpaths are created to show the machine where and how to cut, including depth, speed, and bit selection. The CAM software exports G-code, which is the language CNC routers use to move the spindle with precision.

3. Material is Secured to the Work Surface

The operator places material on the router bed and locks it in place using clamping hardware or a vacuum hold-down system. Proper fixturing ensures the sheet will not shift during cutting and helps maintain tight tolerances.

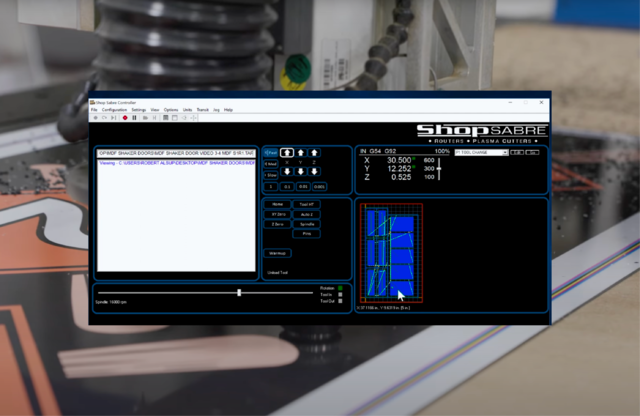

4. The Machine is Set Up for the Job

The operator loads the correct cutting tool into the spindle, sets zero points for the X, Y, and Z axes, and uploads the G-code file to the CNC controller. A quick safety check confirms that everything is positioned correctly.

5. The Router Follows the Programmed Motion

Once started, the CNC router uses servo or stepper motors to guide the spindle along the X, Y, and Z axes. The cutting tool rotates at high speed to remove material exactly where the instructions specify. Depending on the project, the process may include profiling, pocketing, drilling, engraving, or 3D contouring.

6. The Finished Part is Removed and Finalized

When the cut is complete, the part is removed from the table. Some materials are ready to go immediately, while others may need light sanding, polishing, or assembly. Any remaining dust or chips are cleaned from the workspace before the next job runs.

Why Do Businesses Use CNC Routers?

CNC routers are popular among manufacturers because they provide:

- Precise and repeatable results

- Faster production with less manual labor

- Larger cutting areas for full sheet processing

- The ability to scale up from prototypes to volume runs

- Lower cost compared to heavy-duty CNC mills

Industries that rely heavily on CNC router technology include cabinet shops, sign manufacturers, furniture makers, packaging companies, and custom fabrication services.

Ready to Upgrade Your Shop with CNC Routing?

If you are exploring CNC routers for your business, ShopSabre delivers industrial performance without the industrial price tag. Every ShopSabre CNC router is engineered, built, and supported in the USA, giving you the precision, reliability, and service that growing shops count on.

From hobby startups to full-scale manufacturing, our machines help you take on more projects and produce better parts with confidence.

Explore the ShopSabre lineup and find the CNC router that fits your workflow today.

Frequently Asked Questions About CNC Routers

What is the difference between a CNC router and a CNC mill?

A CNC router typically has a larger working area and is optimized for wood, plastics, and aluminum with fast cutting speeds. Mills are built for harder metals like steel and offer tighter tolerances but smaller work envelopes.

What software is needed for CNC routing?

You need CAD software to design the part and CAM software to create toolpaths and G-code. Many systems also include machine control software to operate the router.

Can a CNC router cut metal?

Yes. Most CNC routers can handle softer metals such as aluminum and brass. For thick or hardened steels, a CNC mill or fiber laser is recommended.

Do CNC routers require a lot of training?

Basic operation is easy to learn. Shops usually get comfortable after a short training period with CAD, CAM, and machine setup processes.

How accurate are CNC routers?

Accuracy depends on build quality and components. Industrial routers like ShopSabre machines provide high repeatability that is suitable for precision manufacturing.