Laser vs Plasma Cutting

If you’re stuck trying to decide between laser vs plasma cutting, you’re not alone; we get this question all the time.

The short answer? It depends on what you’re cutting, how precise you need it, and what your budget is when looking for a CNC machine.

Let’s break down plasma cutting vs laser cutting so you know exactly which one fits your job—and your shop.

What’s the Difference Between Laser and Plasma Cutting?

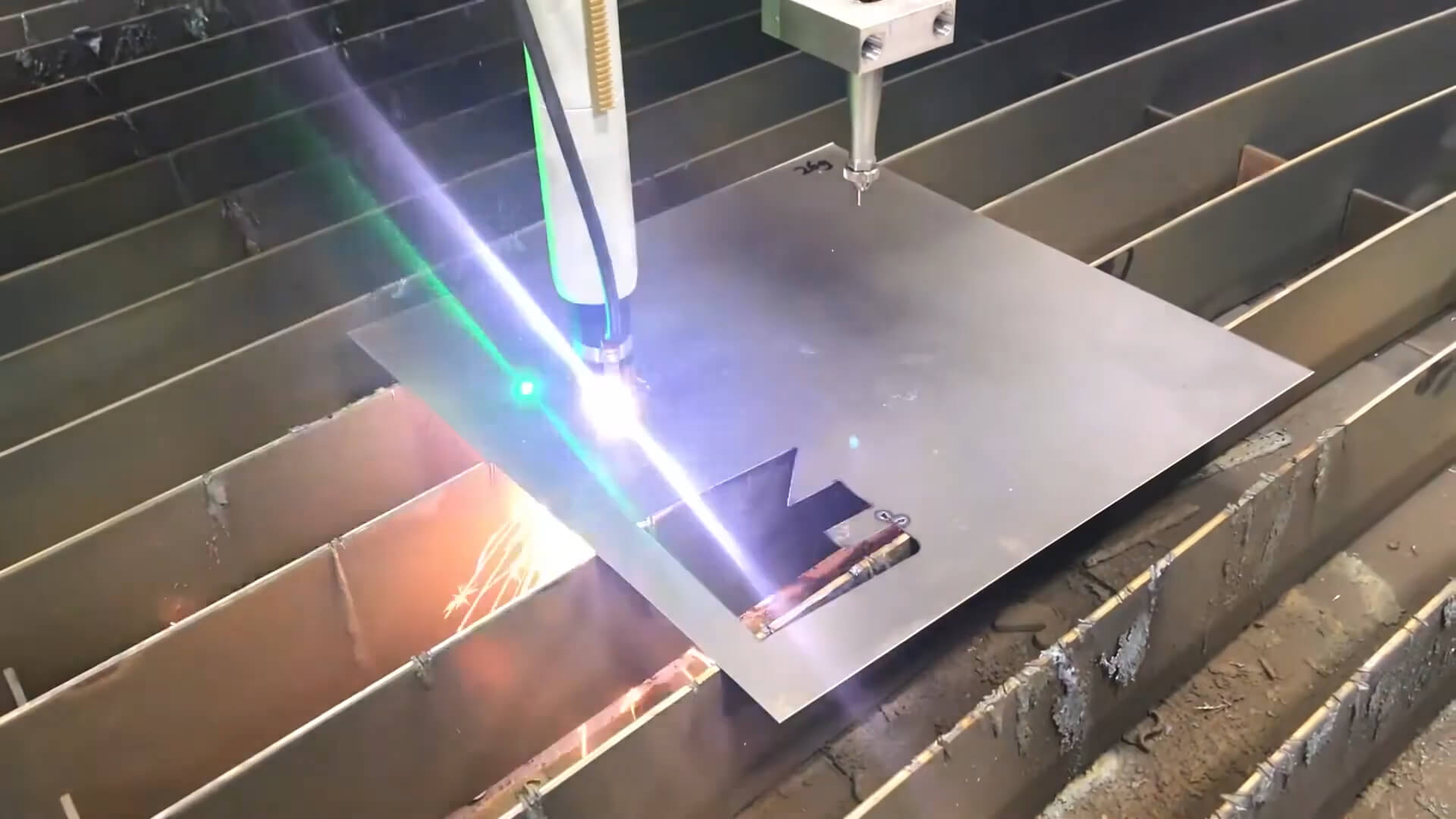

At the core, both processes use high temperatures to cut through metal, but the heat source is what sets them apart:

- Laser cutting uses a focused, high-powered beam of light (typically a fiber laser in today’s CNC machines) to melt or vaporize material. Think precision—tight tolerances, sharp corners, and fine detail.

Plasma cutting relies on an electrical arc and compressed gas to create ionized plasma, hot enough to blast through electrically conductive metals. It’s fast, powerful, and excels at cutting thicker materials with a lower upfront cost.

When to Use Laser Cutting

Laser cutting is your go-to when precision matters. It’s ideal for:

- Tight tolerances (±0.002″–0.005″, depending on material and setup)

- Thin to moderately thick metal (typically up to 1″ on a 6kW+ system)

- Intricate shapes, small holes, and tight inside radii

- Minimal post-processing or secondary finishing

- Marking and engraving of metal and non-metal materials (with appropriate setups)

While fiber lasers are optimized for metals, they can also, in some cases, process some non-metals (e.g., plastics or composites), though important to note that CO₂ lasers are typically better suited for cutting non-metals such as plastics, composites, wood, acrylic, and ceramics.

The downside? Laser systems cost more to purchase and operate, especially when cutting thicker materials or requiring high-speed nitrogen cutting. However, the edge quality, repeatability, and precision can reduce downstream labor and waste.

When to Use Plasma Cutting

If you’re working with thicker metals and prioritize speed and affordability over surgical precision, plasma is a strong option:

- Cuts through thicker metals efficiently (commonly 1″–1.5″, and up to 2″ with high-amperage systems)

- Faster cut speeds on thicker materials than lasers

- Lower upfront and operating costs compared to fiber lasers

Plasma is limited to electrically conductive materials, such as mild steel, stainless steel, aluminum, brass, and copper, and does not handle non-metal materials.

Edge quality is good for many fabrication jobs, but some parts may require post-cut grinding or cleanup, especially for cosmetic or precision applications.

Laser vs Plasma: Side-by-Side Comparison

|

Feature |

Laser Cutting |

Plasma Cutting |

|

Cutting Method |

Focused laser beam |

Ionized gas (plasma arc) |

|

Material Compatibility |

Metals, some plastics/composites (fiber), wood/acrylic with CO₂ |

Conductive metals only |

|

Max Thickness (approx.) |

Up to 1”+ (with high-power fiber) |

Up to 1.5”- 2”+ (depends on amperage) |

|

Precision |

Very high (±0.002″ – 0.005”) |

Moderate (±0.010″–0.030″) |

|

Speed |

Slower on a thick plate, faster on a thin gauge |

Fast on a thick plate |

|

Initial Investment |

Higher |

Lower |

|

Maintenance Needs |

Lower (fewer consumables, sealed beam) |

Moderate (electrodes, nozzles, shields) |

|

Finish Quality |

Clean edges, minimal dross |

May require cleanup, more dross |

Shop Environment: What to Expect

Let’s talk shop.

CNC lasers require a cleaner, more controlled environment. Dust, temperature swings, and voltage instability can impact performance, especially over time. Clean air, stable power, and temperature control help protect sensitive components and optics.

Plasma machines, on the other hand, are built tougher—ideal for gritty, high-output metal shops. They tolerate fluctuating conditions and dirty air better, making them a better fit for rougher environments.

That said, every ShopSabre system—laser or plasma—is built to work in real-world conditions. We design our machines for welders, fabricators, and production shops—not for lab coats and rubber gloves.

But if you’re investing in a high-precision laser, it deserves an environment where it can perform at its best. Think of it like a performance car—it’ll run on the street, but it truly shines on the track.

Which One’s Better?

The truth is, it depends on what you’re cutting, how thick it is, and how clean you need it to be.

Here’s a quick recap of when to use each method:

- Choose a CNC laser if you’re cutting thin to medium-thickness parts with tight tolerances or detailed geometry.

- Choose a CNC plasma if you’re cutting thick metal quickly and don’t need ultra-fine detail.

There’s no one-size-fits-all answer in the laser vs plasma debate. Each method has its strengths, and the right choice usually comes down to your project’s demands—precision, speed, material, and budget.

How ShopSabre Can Help

At ShopSabre, our CNC plasma and laser cutting systems are built like tanks and dialed for performance. Whether you’re cutting quarter-inch aluminum all day or building heavy equipment brackets out of thick plate, we’ve got a machine that’ll make your life easier and your shop more profitable.

Still not sure which one’s right for your workflow? Give us a call or check out episodes 53 and 189 of the official Talkin Shop podcast—we dive into the real-world pros and cons of CNC laser vs plasma from the shop floor perspective.