Best CNC Plasma Table: How to Choose the Right Machine for Your Shop

If you are searching for the best CNC plasma table, you are likely balancing more than just price. Accuracy, reliability, software freedom, long-term support, and real-world performance all matter, especially in a business environment where downtime costs money.

The challenge is that there is no single “best” CNC plasma table for everyone. The best CNC plasma cutter depends on how you plan to use it, what materials you cut, how often you run it, and how much flexibility you need as your business grows.

This guide breaks down what actually matters when evaluating top CNC plasma tables, what separates professional-grade machines from budget shortcuts, and how to determine the best CNC plasma table for your operation.

What is a CNC Plasma?

A CNC plasma table is a computer-controlled cutting system designed to cut conductive metals using a plasma arc. The table provides a stable cutting surface, while a gantry system moves the plasma torch precisely across the material based on programmed toolpaths.

Most CNC plasma tables include:

- A welded steel table with slats and either a water table or a downdraft system

- Linear motion rails and a rigid gantry

- Motor-driven axes for X, Y, and Z movement

- A CNC controller that executes the cutting program

- Torch height control for consistent cut quality

The quality of each of these components plays a direct role in cut accuracy, consumable life, and overall machine longevity.

Why Plasma Cutting Works So Well with CNC Tables

Plasma cutting is well-suited for CNC automation because it delivers fast, consistent cuts across a wide range of metal thicknesses. A plasma arc uses ionized gas to melt metal, while the arc pressure blows molten material away from the cut.

This process allows CNC plasma tables to:

- Cut mild steel, stainless steel, aluminum, brass, and copper

- Handle both thin sheet metal and thicker plate

- Achieve high cut speeds compared to oxyfuel

- Reduce secondary operations like grinding

For most fabrication shops, plasma provides the best balance of speed, cost, and versatility.

What Makes the Best CNC Plasma Table?

When evaluating the best CNC plasma table for your shop, focus on these core factors rather than the surface-level marketing claims.

Frame and Gantry Construction

Rigid steel construction matters. Welded, stress-relieved steel frames resist vibration and flex, which directly improves cut accuracy and edge quality. Lightweight bolt-together frames may reduce upfront cost, but they often sacrifice long-term precision.

Motion Control and Motors

High-quality CNC plasma tables use industrial-grade motors with encoder feedback. This allows the machine to maintain accuracy at higher speeds and reduces the chance of lost steps or positional errors during long runs.

Integrated Torch Height Control

Torch height control is not optional if you care about the quality of your cuts. Integrated THC systems automatically adjust torch height during cutting, maintaining proper arc voltage and consistent edge angularity. Integrated systems outperform external add-on units by simplifying operation and improving reliability.

Software Freedom and At-Machine Control

Some machines lock users into proprietary software ecosystems. Others allow you to run non-proprietary CAD and CAM software directly on the machine.

At-machine software freedom allows you to choose tools like Fusion 360, SheetCAM, ProNest LT, or EnRoute based on your workflow instead of vendor restrictions.

Support, Training, and Warranty

A CNC plasma table is a long-term investment. Strong technical support, training resources, and a comprehensive warranty often matter more than small price differences.

Best CNC Plasma Table for the Money

Many buyers are searching for the best CNC plasma table for the money, meaning they want professional performance without paying for unnecessary extras.

Value comes from:

- Industrial-grade components

- Software flexibility

- Long-term reliability

- Ongoing support and training

Machines that deliver these fundamentals consistently outperform cheaper tables that cut corners on structure, electronics, or torch height control.

What About The Best CNC Plasma Table for Garage Shops?

Garages are a common spot for plasma tables, or really any CNC machine, when we talk about hobby or small business use. The best CNC plasma table for garage use need to provide adequate footprint, power, and over-all usability.

Garage-friendly plasma tables typically:

- Fit within 4×4 or 4×8 cutting areas

- Operate on standard shop power

- Use water tables for fume control

- Offer simple setup and intuitive controls

These machines are popular with small fabrication shops, metal workers, and business owners scaling up from manual cutting.

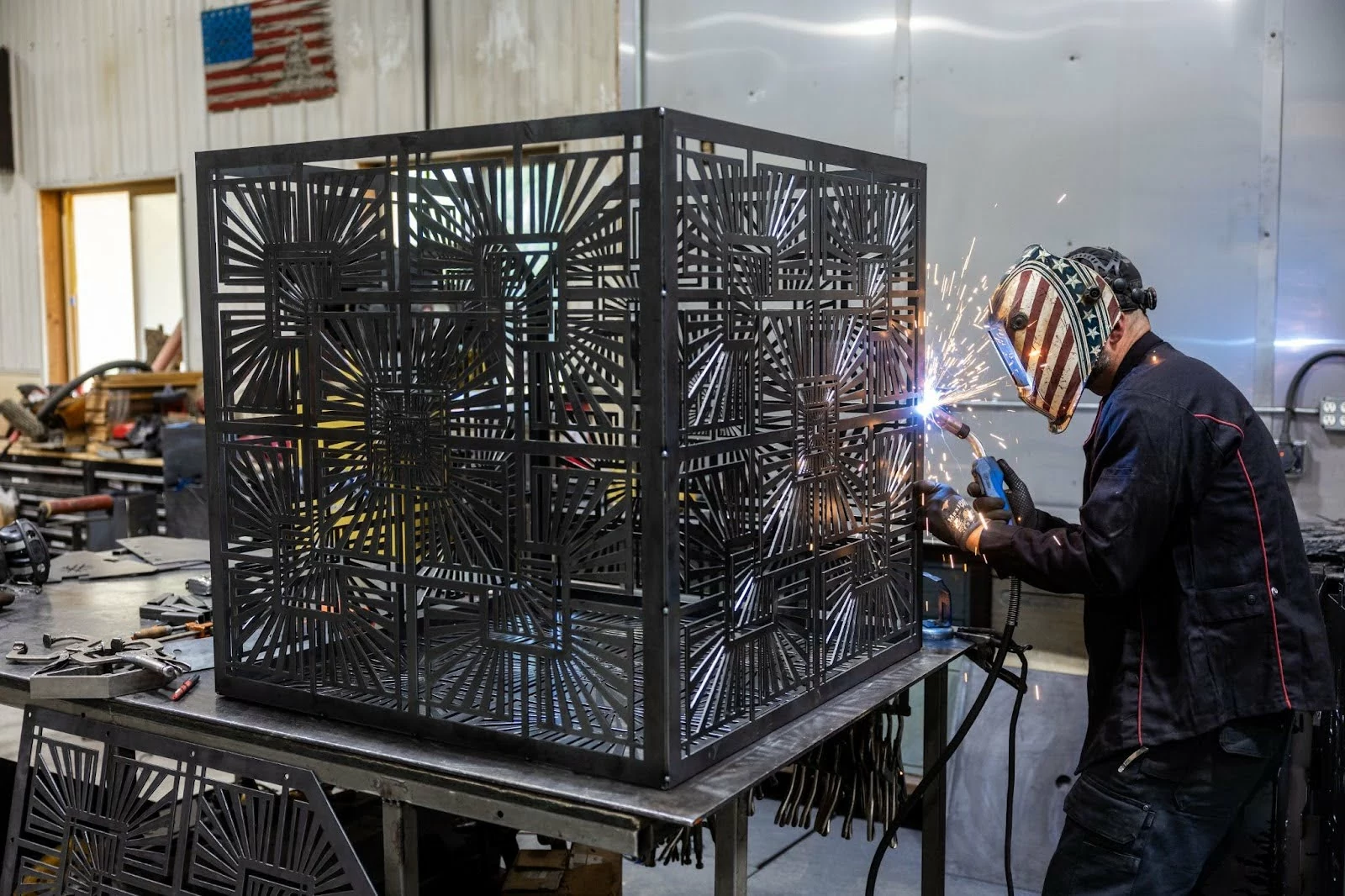

What Can You Make with a CNC Plasma Table?

CNC plasma tables are used across industries ranging from hobby fabrication to full-scale manufacturing.

Common applications include:

- Structural brackets and mounting plates

- Metal signage and decorative art

- Automotive parts and repair components

- Agricultural equipment parts

- Custom enclosures and panels

The ability to cut repeatable shapes quickly makes CNC plasma a non-negotiable for shops that truly value efficiency and consistency in their work.

Top CNC Plasma Tables from ShopSabre

The SideKick CNC Plasma

The SideKick CNC Plasma is designed to deliver industrial performance at an entry-level price point. It is engineered, built, and supported in the USA and is intended for both light and full-time production use.

Key advantages include:

- Fully welded, stress-relieved steel frame and gantry

- Closed-loop brushless motors with encoder technology

- Integrated torch height control for consistent cut quality

- Multiple size option, including SideKick 4, 8, 10, and 12

- Optional router functionality for added versatility

This machine is well-suited for fabrication shops, automotive businesses, educational facilities, and manufacturers that need flexibility without sacrificing precision.

ShopMaster Series CNC Plasma

The ShopMaster Series CNC Plasma is built for shops that need serious cutting power, long run times, and industrial reliability without stepping into six-figure pricing. Designed and manufactured in the USA, the ShopMaster is engineered to support demanding production schedules, including multi-shift operation and heavy-duty material cutting.

Key advantages include:

- Welded, non-suspension structural steel frame that keeps weight at floor level for maximum rigidity

- Industrial structural tube steel gantry engineered for precision and long-term durability

- AC digital closed-loop servo motors with glass encoders on X, dual Y, and Z axes

- Integrated digital torch height control with Ohmic Touch and Touch Distance Control

- Direct-drive planetary gearing on the XY-axis and ball screw-driven Z-axis

- Integrated 24-inch water table with pneumatic air bladder for fast water level adjustment

- Optional automated zone-controlled downdraft system for high-production environments

- Rapid cutting speeds up to 2,500 IPM for efficient throughput

- Compatible with Hypertherm XPR and Thermal Dynamics UltraCut systems for HD plasma cutting

The ShopMaster Series is well suited for manufacturing plants, fabrication shops, automotive operations, and industrial users that need consistent accuracy, clean cuts, and equipment that can keep up with demanding workloads day after day.

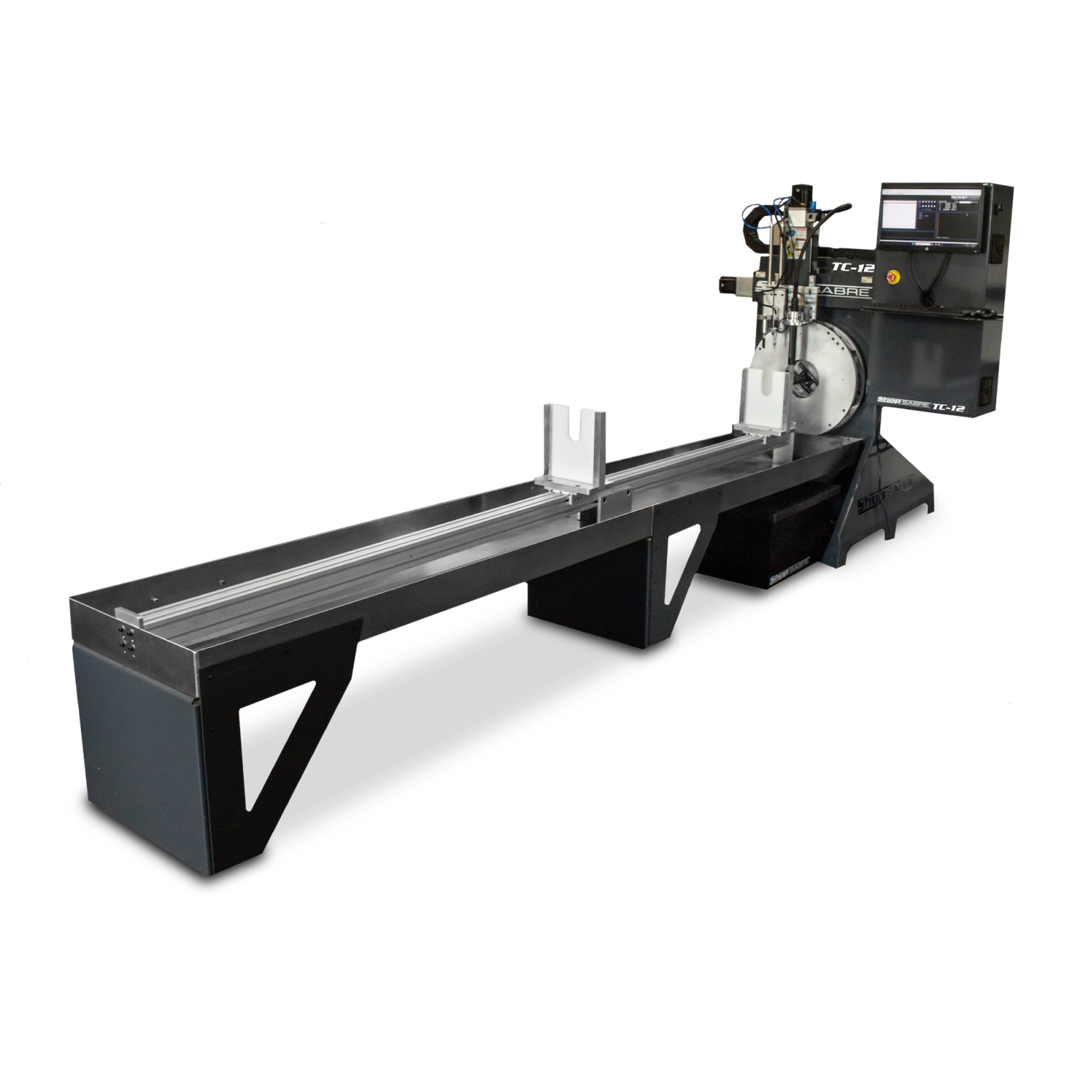

Honorable Mention: ShopSabre Tube Cutter (TC) Series

The ShopSabre Tube Cutter Series is purpose-built for precision tube and pipe cutting. Proudly engineered and manufactured in Lakeville, Minnesota, the TC Series delivers industrial reliability backed by lifetime support and training.

This system allows shops to cut round, square, and rectangular tubing from a single machine, making it ideal for decorative metalwork, motorsports fabrication, automotive and off-road builds, exhaust systems, and general pipe fabrication.

Available configurations include:

- TC-12 for up to 12-foot tube processing

- TC-24 for up to 24-foot tube processing

- Choice of round-only chuck or advanced chuck for round, square, and rectangular tube

Standard and highlighted features include:

- Industrial-grade frame with steel 8-inch tailstock supporting up to a 7-inch hypotenuse passthrough

- Onboard computer system with ShopSabre controller and Windows operating system

- Hypertherm Rotary Tube Pro software included for optimized tube cutting workflows

- Torch collision detection for enhanced safety and reduced downtime

- Laser sight for fast and accurate XY zeroing

Optional upgrades include:

- 4-jaw chuck for expanded tube shape capabilities

- Marking package with marker pen and scribe for engraving and layout marking

- Hypertherm plasma cutter compatibility with Powermax 45, 65, 85, and 105 models

- SabreCool water cooling and water table options in 4-foot and 12-foot sizes to reduce heat distortion, extend consumable life, and improve fume control

For shops looking to streamline tube fabrication and expand cutting capabilities beyond flat sheet metal, the ShopSabre TC Series offers a powerful and scalable solution.

Common Mistakes When Choosing a CNC Plasma Table

Overvaluing Price Alone

The cheapest CNC plasma table often costs more over time due to maintenance, downtime, and poor cut quality.

Ignoring Software Flexibility

Proprietary software limitations can slow production and restrict growth.

Skipping Torch Height Control

Lack of integrated THC leads to poor edge quality, increased consumable wear, and inconsistent results.

Underestimating Support Needs

Reliable technical support and training resources save time and reduce frustration.

How to Decide Which CNC Plasma Table Is Right for You

Ask yourself:

- What materials and thicknesses do I cut most often?

- How many hours per week will the machine run?

- Do I need room to grow into higher production?

- Do I want software flexibility or a locked system?

- What level of support do I expect after purchase?

Answering these questions clearly makes it much easier to identify the best CNC plasma cutter for your needs.

Making the Right CNC Plasma Table Investment

The best CNC plasma table is the one that fits how you actually work, not just what looks good on a spec sheet. Solid construction, reliable torch height control, the freedom to run the software you prefer, and dependable support will matter every day you use the machine.

It doesn’t matter if you’re running parts in a small shop, growing a fabrication business, or bringing more cutting in-house, a well-built plasma table shows its value quickly through cleaner cuts, fewer mistakes, and less downtime.