The truth about rack and pinion drive systems in CNC

Metal cog tooth wheel and rack

In the earlier days of CNC, rack, and pinion drive systems were the go-to standard for lower-cost routing systems. Technology has come a long way since then, as we’ve seen ball screw technology become much more popular in terms of powering CNC machines.

Still, there exists a broad range of misinformation in the industry today regarding rack and pinion drive systems, how they work, and how they compare to ball screw technology in terms of producing high-quality results.

At ShopSabre, our in-house team of expert engineers has extensive experience in both rack and pinion drive systems and ball screw technology, using rack and pinion on several applications, including our SideKick and ShopMaster plasmas and our RC Series router.

Here is a closer look at how rack and pinion drive systems work, their advantages and shortcomings, and how they compare to ball screw technology.

How a rack and pinion drive system works

As the name suggests, there are two key components to a rack and pinion drive system the rack and the pinion.

The rack is a set of teeth that bolts onto the side of the frame of the CNC machine.

The pinion is a cog or gear that meshes with the rack.

As the pinion turns, the machine moves.

One of the key shortcomings of rack and pinion machines is that the fit between the rack and the pinion can’t be perfectly tight or the machine will lock up. Instead, there needs to be about .003-.005 of play on both ends, which is known as backlash and can be difficult to eliminate.

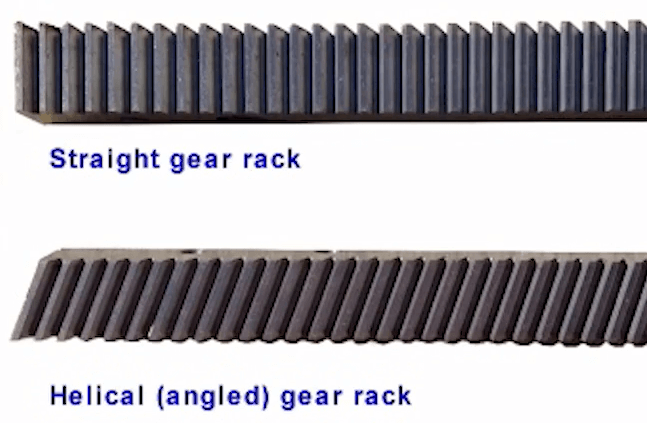

Straight gear rack vs. Helical gear rack

When dealing with machines priced at under $60,000, there are generally two rack and pinion technology options straight gear rack and helical gear rack.

The helical gear rack differs in that it is angled with more teeth, creating a smoother, lower-friction movement. The design is also a little bit quieter, has a higher uptime, and is built to travel the full distance of the machine without any concerns of screw whip.

Operators may be able to get by with a smaller helical gear rack due to the larger contact area, but this comes with a significant tradeoff as it creates side forces that cause wear on associated components. This leads to increased maintenance on things like planetary drives in the long term. Smaller machining on the front end can also cause issues, as racks are fairly soft and often wear out much more quickly than ball screw systems.

Compensating for variability

Rack and pinion systems lend themselves to an increase in variability, which is an issue in precision machining where tolerances need to be extremely tight. To compensate, many operators teach the machine to control the variability, which works fine until backlash occurs. In most cases, this becomes inevitable as something you simply need to live with when using a rack and pinion system. It might matter on some projects and might not matter on others depending on the application, but is in any case something operators just have to accept.

At ShopSabre, our solution is to avoid using rack and pinion technology on our machine tool-grade routers, instead opting for the improved toughness, precision, and overall performance of ball screws. There are several machines we do use rack and pinion on, such as CNC plasmas where the torch already creates so much variability or lower-cost machines that cant afford the use of a more expensive drive system.

Still, for projects in need of improved resistance to wear and tear, improved precision, and greater cut forces and machine movements, we recommend utilizing a machine with ball screw technology.

Experience CNC the way it was meant to be with ShopSabre

At ShopSabre, our in-house engineering talent has extensive expertise in motion control and always aims to provide hobbyists and shop owners alike with unmatched precision, efficiency, and versatility. Whatever your goals, we are dedicated to helping you produce outstanding results at a fraction of the labor and cost.

Here are a few of the reasons ShopSabre can develop and produce such revolutionary CNC technology:

- Experienced in-house engineering talent

- The ability to fabricate and test designs on-site from start to finish

- The ability to place the designs into production in-house

Shop our unmatched collection of CNC routers and CNC plasmas in Minneapolis today to experience CNC the way it was meant to be.