The truth about ball screw technology in CNC routers

Ball screw technology vs. rack and pinion is one of the more common comparisons in the world of CNC, with both opposing viewpoints changing over time as technology has evolved.

While ball screw technology has come a long way over the past couple of decades, there are still a lot of widespread misconceptions about it and how it pertains to CNC work.

Here’s a breakdown of how ball screw technology works and why it delivers better results for your CNC router.

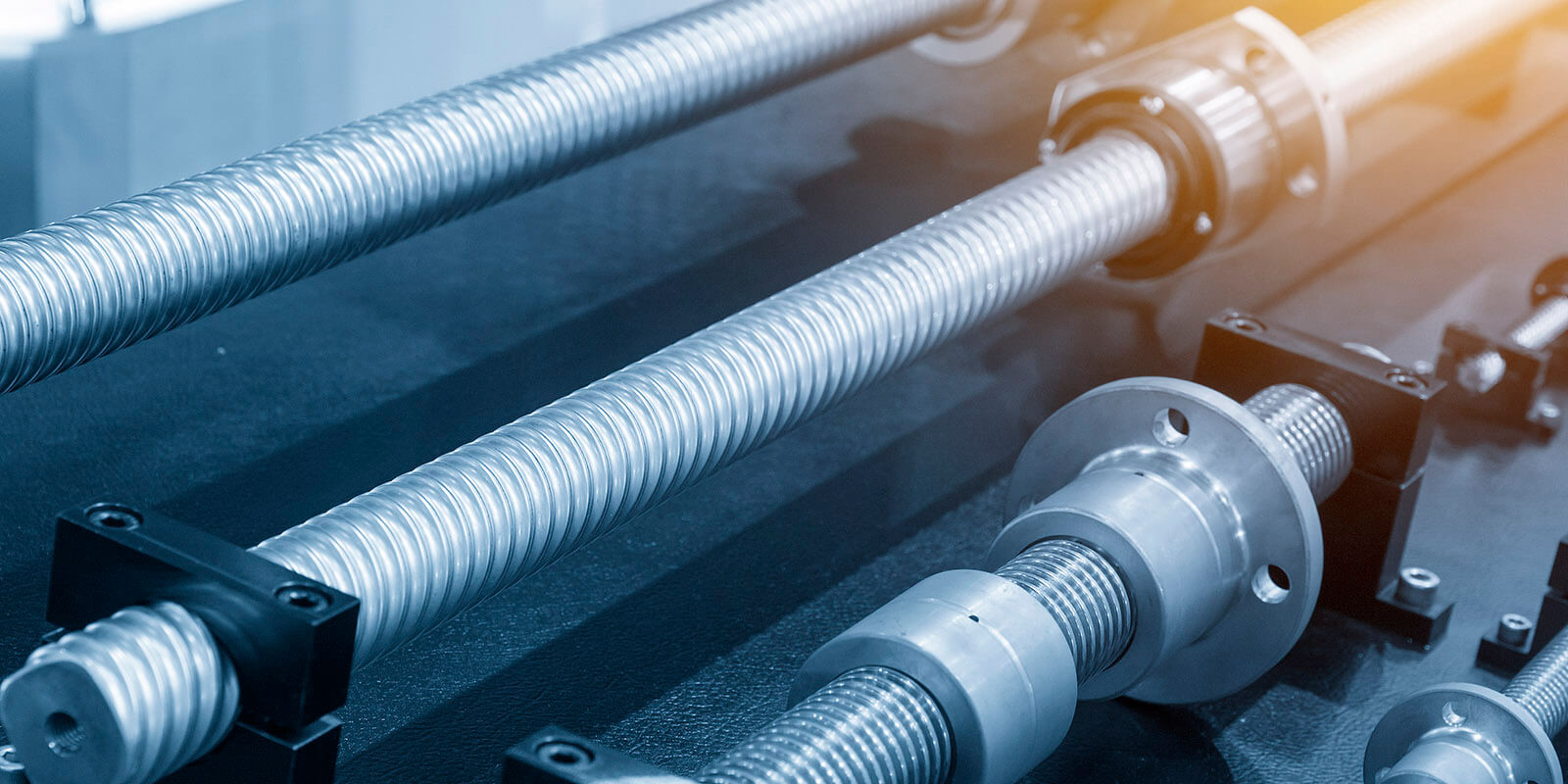

How ball screw technology works

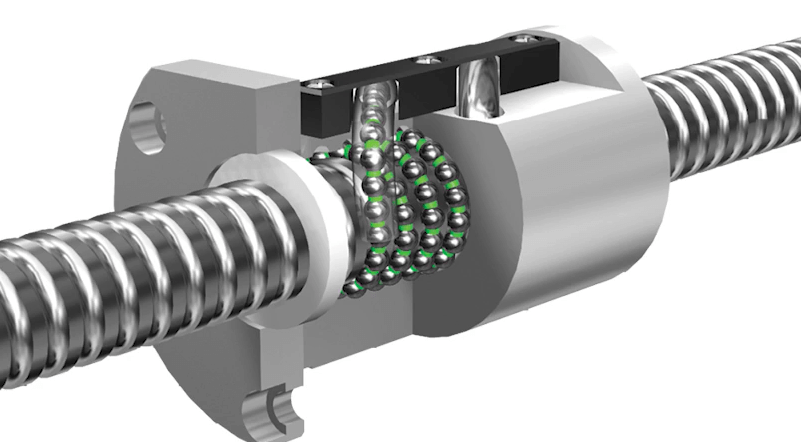

To understand ball screw technology, we need to start with two key components: the ball screw and the ball nut. Between these two, there are tiny ball bearings that circulate in tracks. As the screw turns, the bearings also turn freely.

The reason the bearings can move freely is that they’re oversized by a few microns, preventing any unwanted play. This is known as preload and is the reason there is no backlash in ball screw systems. (Backlash is any clearance or lost motion in a mechanism caused by gaps between the parts.)

The growth of ball screw

Until 20 years ago, it was highly common to turn ball screws (and we still do it on the shorter axis). This worked fine for the most part until high-speed machining came along from the machine control industry as they learned how to process things more quickly.

In the old system, there were frequent problems with ball screw whipping. The new ball screw technology keeps the screws stationary and rotates the ball nut, allowing machines to operate as efficiently as they want.

No-backlash benefit

During the manufacturing process, it’s common for even the highest-precision components to have some variability. But another one of the great things about ball screws is that this variability doesn’t create any issues.

Because there’s no backlash in ball screw systems, it’s very easy for the machine control to compensate for variability, delivering the same level of precision all over the table. This is made possible because of the lack of backlash. The presence of backlash changes everything, and once it’s there, it’s very difficult to correct.

Produce better parts with ball screw technology from ShopSabre

By and large, a ball screw CNC machine is going to produce better parts, operating in a way that is more precise and with fewer issues.

While they may be more expensive to produce on the front end due to the need for a properly designed frame and properly spaced components, the result is a highly precise and magnificent machine tool that is worth the investment.

Ball screw machines also last a long time. Many operators think they can save some money by investing in a rack and pinion machine, but this is often not the case. A typical ball screw may last 15 years, while a rack and pinion system will almost always wear out much sooner.

This is one of many reasons we use ball screw technology on all of our ShopSabre machine tool-grade CNC routers. Our in-house engineering talent has extensive expertise in motion control and always aims to provide hobbyists and shop owners alike with unmatched precision, efficiency, and versatility. Whatever your goals may be, we are dedicated to helping you produce outstanding results at a fraction of the labor and cost.

Our Industrial Series (IS) and SeriesCNC routers provide an industrial capability for a fraction of the price, while our SideKick CNC plasmas deliver professional quality at an entry-level cost.

Here are a few of the reasons ShopSabre can develop and produce such revolutionary CNC technology:

- Experienced in-house engineering talent

- The ability to fabricate and test designs on-site

- The ability to place the designs into production in-house

These are just a few of the advantages of being an American machine tool manufacturer. We offer commercial financing on our CNC equipment to help meet the needs of your budget.

Shop our unmatched collection of CNC routers and CNC plasmas in Minneapolis today to experience CNC the way it was meant to be.