How to Choose the Best CNC Router for Your Cabinet Shop

If you’re running a cabinet shop, your CNC router is the heart of your production. Whether you’re building custom kitchen cabinets, bathroom vanities, or high-volume cabinet runs for commercial spaces, choosing the best CNC router for your cabinet shop can make or break your workflow, margins, and customer satisfaction.

So, how do you choose the right machine? That depends on the kind of shop you run, the materials you work with, and how far you want to grow.

Let’s break it all down, from machine size and speed to software, support, and maintenance.

What is a CNC Router? (& Why Cabinetmakers Rely on Them)

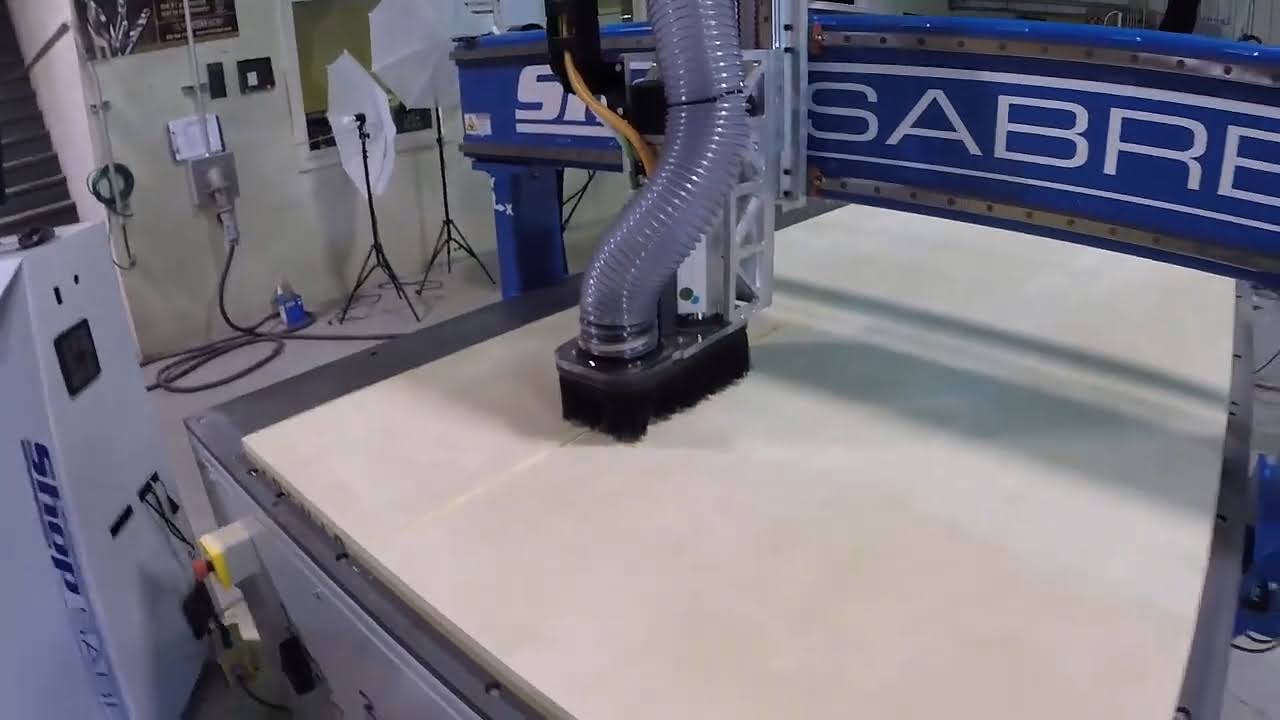

A CNC router (short for Computer Numerical Control router) is a computer-controlled cutting machine that can carve, drill, and shape wood, plastics, and even composites with pinpoint accuracy. In cabinetmaking, CNC routers handle repetitive cuts and complex shapes faster, cleaner, and more precisely than manual methods.

Instead of measuring and cutting each part by hand, you create your cabinet designs in CAD/CAM software, and the CNC router takes it from there, delivering precise cuts and repeatable results every single time. That means faster turnarounds, fewer mistakes, and the ability to take on more jobs with fewer hands.

Whether you’re a one-man custom shop or running a high-output production floor, the best CNC router for cabinet shops should make your life easier, not more complicated.

Key Factors to Consider When Choosing a CNC Router for Cabinets

Not all routers are the same. Here’s what really matters when picking the right one for your shop:

1. Size and Work Area

Think about the size of sheet goods you regularly process. Most cabinet shops work with 4′ x 8′ plywood or MDF sheets, so a machine that can comfortably handle those dimensions — ideally with some extra space — is a must.

Tip: Right-size your machine, buying smaller than you need can lead to having to buy an entirely new machine in a short time—buying too big of a machine can lead to production challenges such as vacuum hold down.

2. Speed and Production Capability

Speed isn’t just about how fast the router moves — it’s about how quickly and cleanly it completes a job without sacrificing quality.

Look at features like:

- Rapid traverse speed (how fast the machine moves between cuts)

- Cutting feed rate (how fast the machine moves when making you money)

- Spindle horsepower at 100% duty—don’t fall into the marketing gimmicks

- Tool Change Processes—Look for automatic tool changers (ATCs) that minimize downtime between operations, especially on jobs with multiple tool paths.

These directly impact your shop’s output. If you’re planning to grow your shop or add a second shift, invest in a machine that can keep pace.

3. Accuracy and Repeatability

Cabinetmaking requires tight tolerances, especially for box construction, face frames, MDF doors, dovetail drawers, and drawer slides. A quality CNC router should deliver precise cuts every time, not just on Day 1, but for years to come. This depends on:

- Rigid frame construction

- Closed Loop (Servos) vs. Open Loop Motors (Steppers)

- Ball screw vs. rack-and-pinion drives

Accuracy affects how everything fits together, today, and in the future after hours of run time. All of which impacts your customers satisfaction and business profit line.

4. Software Compatibility

A CNC machine is only as good as the software that runs it. For cabinet shops, that means seamless compatibility with design software like:

- Vectric VCarve or Aspire

- Cabinet Vision

- KCD

- Cabinet Pro

- Fusion 360

- Mozaik

The best CNC routers for cabinet shops should integrate with the software you already use (or plan to). Be cautious of proprietary programs that leave you handcuffed.

5. Material Compatibility

Most cabinet shops primarily cut plywood, MDF, particleboard, and hardwoods. But, what if you need to expand into Live Edge, Solid Surface, Plastics, or even Foam inserts? Make sure your machine can handle the materials you plan to cut, not just today, but down the line.

Higher-end routers offer better quality spindles, upgraded vacuum gold down systems, and more efficiency, all of which help when working with more advanced jobs.

6. The Cost of a CNC Router for Cabinet Shops

CNC routers can range from just over $10,000 to well north of $100,000 — so how do you know what’s worth paying for?

In general, the more rigid, powerful, and production-ready the machine is, the higher the price tag. But it’s not just about size or spindle speed. The cost of a CNC router is tied to everything from the quality of components and motor type to software compatibility, support, and long-term reliability.

For cabinet shops, it’s important to think about the total cost of ownership, not just the sticker price. A cheaper machine may save you money upfront, but cost you in downtime, maintenance, or bad cuts down the line. On the other hand, a precision-built machine like a ShopSabre may be a more manageable investment up front, and it’ll pay for itself in output, accuracy, and years of reliable service.

The Right machine, oftentimes, has a better ROI.

If you’re wondering why CNC machine prices vary so widely — and what you’re really paying for — this breakdown of what contributes to pricing variances in CNC machines is a great place to start.

Don’t Forget Maintenance and Support

The best CNC router for a cabinet shop isn’t just about features — it’s also about how long the machine will last and who will support you when things go sideways.

Look for:

- U.S.-based support staff

- Training materials and onboarding assistance

- Easy access to replacement parts

- Preventative maintenance recommendations

ShopSabre shines here, offering top-tier customer support and maintenance guidance. Our routers are also known for low long-term ownership costs compared to imported machines.

Whatever you choose, investing in the best CNC router for your cabinet shop means better quality, greater consistency, and the ability to confidently take on more jobs.

If you’re just starting to research your CNC workflow, check out our article on how to build cabinets for insight into the design-to-cutting process.